Corrosion inhibitor used for reforming device, and preparation method thereof

A reformer and corrosion inhibitor technology, which is applied in the fields of treatment equipment corrosion/fouling inhibition, petroleum industry, and hydrocarbon oil treatment, etc. Corrosion inhibition effect, slowing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

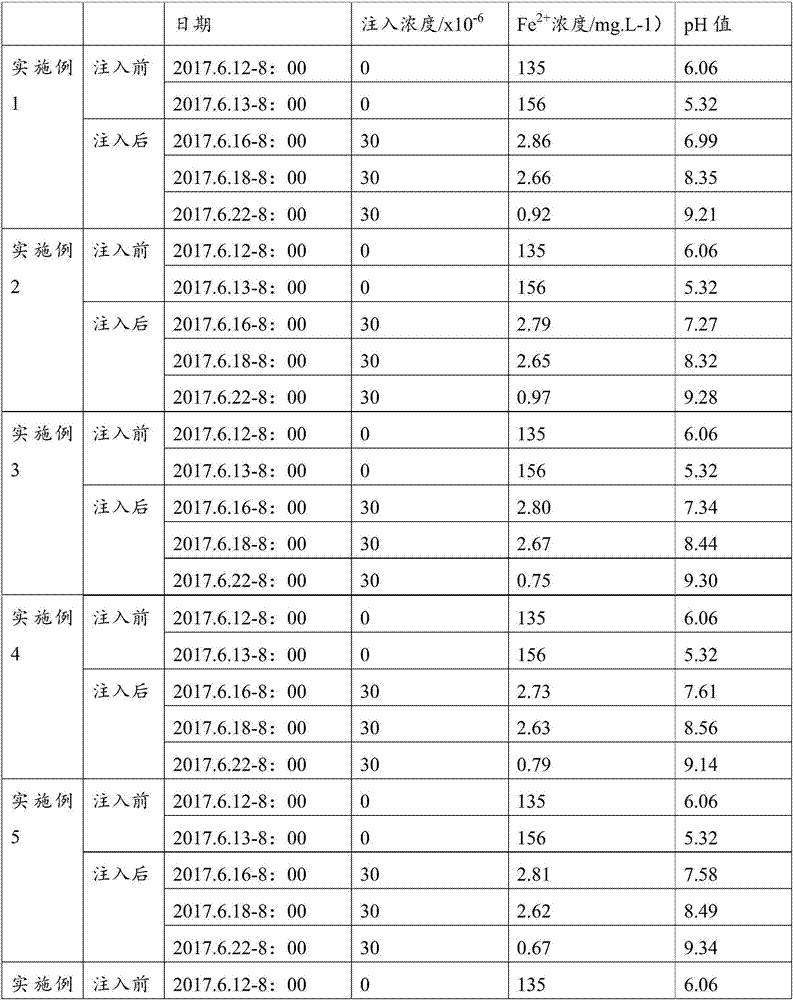

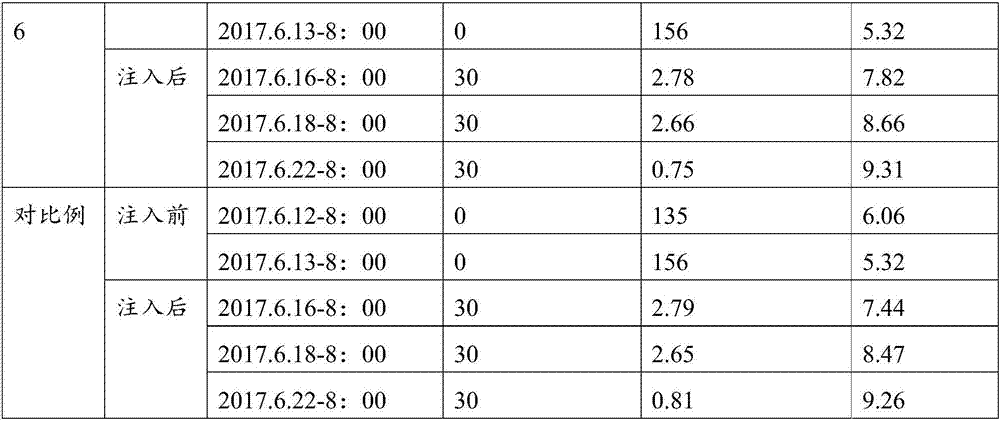

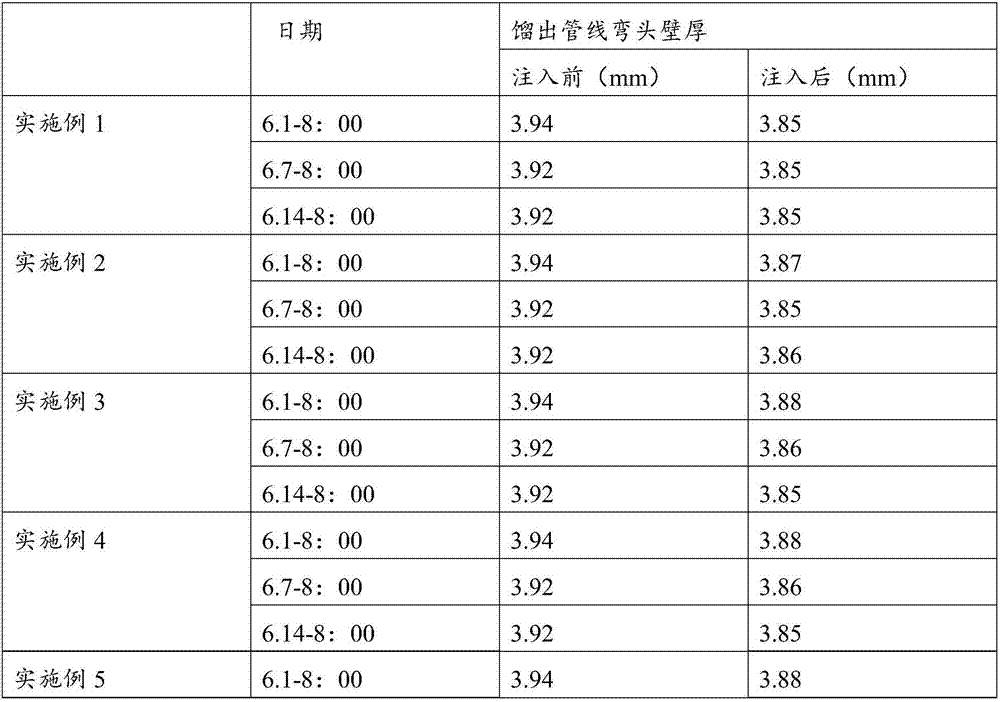

Examples

Embodiment 1

[0021] The corrosion inhibitor for reforming unit of the present invention includes an amine compounding agent, and the amine compounding agent is composed of 40% by weight of monoethanolamine, 40% by weight of diethanolamine and 20% by weight of triethanolamine.

[0022] The preparation method of corrosion inhibitor for reforming unit of the present invention comprises the following steps:

[0023] Take ethylene oxide and ammonia, the ratio of the amount of ethylene oxide to ammonia is 1:4, the reaction needs to be carried out under pressure, the operating pressure is 15Mpa, the temperature is 130°C, react for 2 hours, and then gradually Cool to room temperature to obtain the product amine complex agent, wherein monoethanolamine, diethanolamine and triethanolamine are respectively 40%, 40% and 20%.

Embodiment 2

[0025] The corrosion inhibitor for reforming unit of the present invention includes an amine compounding agent, and the amine compounding agent is composed of 50% by weight of monoethanolamine, 35% by weight of diethanolamine and 15% by weight of triethanolamine.

[0026] The preparation method of corrosion inhibitor for reforming unit of the present invention comprises the following steps: get oxirane and ammonia, ammonia is dissolved in water, the concentration in water is controlled at 50%, the amount of substance of oxirane and ammonia The ratio is 1:5, and the reaction needs to be carried out under pressure. Usually, the operating pressure is 16Mpa, the temperature is 150°C, the reaction is for 2 hours, and then gradually cooled to room temperature to obtain the amine complex agent, in which monoethanolamine 30%, di Ethanolamine 35%, triethanolamine 15%.

Embodiment 3

[0028] The corrosion inhibitor for reforming unit of the present invention includes an amine compounding agent and a synergist, and the weight ratio of the synergist to the amine complexing agent is 1:1;

[0029] The amine compounding agent is composed of 40% by weight of monoethanolamine, 45% by weight of diethanolamine and 15% by weight of triethanolamine;

[0030] The synergist includes glycerol and citric acid, and the weight ratio of glycerol and citric acid is 1:1.

[0031] The preparation method of corrosion inhibitor for reforming unit of the present invention comprises the following steps:

[0032] (1) Take ethylene oxide and ammonia, the ratio of the amount of ethylene oxide to ammonia is 1:4~5, the reaction needs to be carried out under pressure, usually the operating pressure is 15Mpa, the temperature is 150°C, the reaction 2 hours, then gradually cooled to room temperature to obtain an amine complex agent, wherein monoethanolamine was determined to be 40%, dietha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com