Preparation and application of a spark plasma sintered aluminum matrix composite material for hydrogen production

A technology of discharge plasma and aluminum-based compounding, which is applied in the energy field, can solve the problems of degraded hydrogen desorption performance and high corrosion resistance of equipment, and achieve the effects of improving hydrogen production performance, being easy to carry safely, and improving the poor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

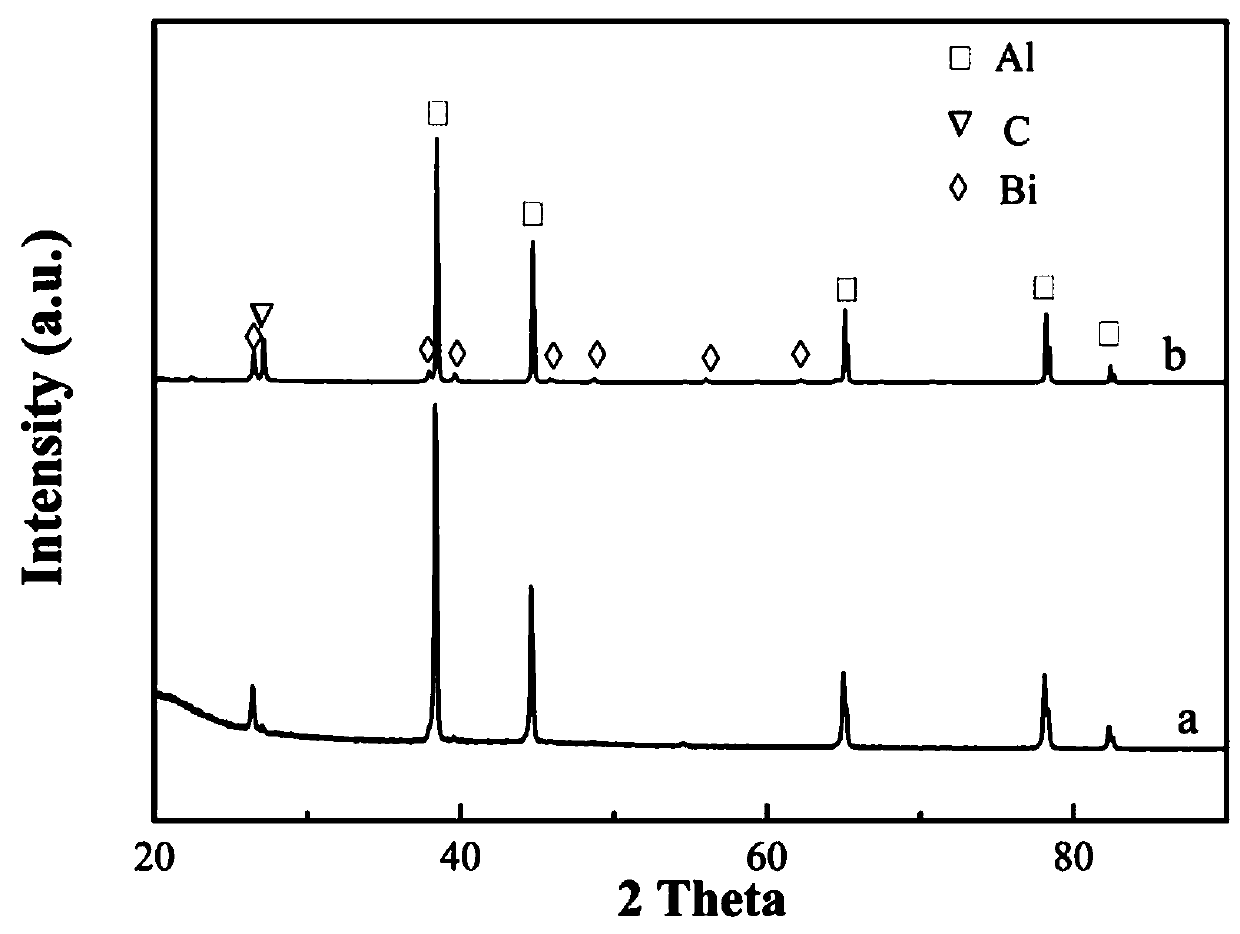

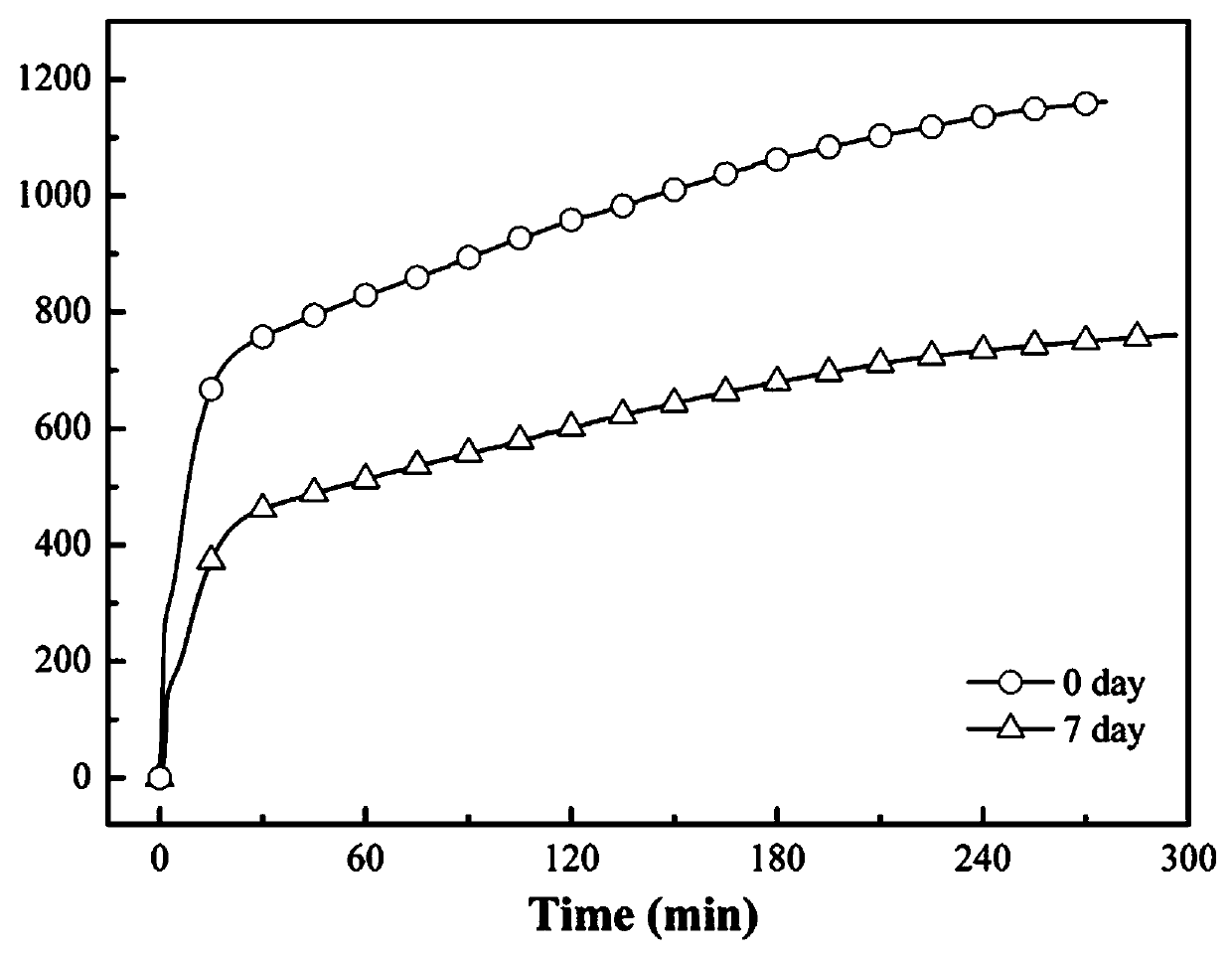

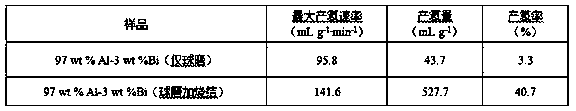

[0028] An aluminum-based composite hydrogen-producing material sintered by spark plasma, comprising the steps of:

[0029]Step 1) Ball milling process, under the protection of argon environment, according to the mass ratio of Al powder, Bi powder and carbon material is 2.85:0.09:0.06, weigh 2.85 g micron-sized Al, 0.09 g Bi and 0.06 g carbon material mixed powder A total of 3 g was added to the ball mill jar, and then about 60 g of balls were added at a ball-to-material ratio of 20: 1, sealed, and then the ball mill jar was put into the ball mill for ball milling. The ball milling speed was 50 r / min, and the ball milling time was 30 minutes. min, to obtain a homogeneously mixed aluminum matrix composite hydrogen production material. Among them, the carbon materials are carbon nanotubes (CNTs), graphene (G), graphene oxide (GO), activated carbon (AC) or graphite (GR);

[0030] Step 2) During the SPS sintering process, take out the uniformly mixed aluminum-based composite hydro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com