A method for treating gobs with steel pipe columns

A goaf and steel pipe column technology, applied in mining equipment, earth-moving drilling, mining equipment and other directions, can solve the problems of reduced pile stability and bearing capacity, increased construction cost and difficulty, and increased pull-down load, etc. The effect of improving efficiency, reducing treatment area and reducing material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

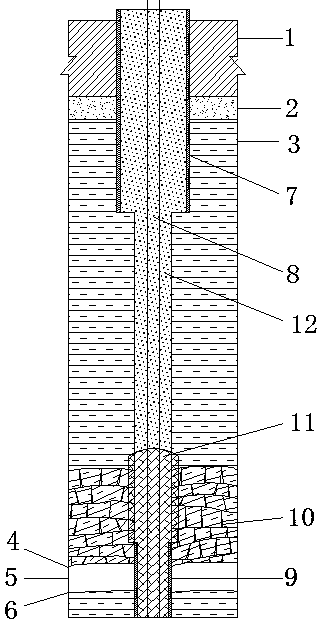

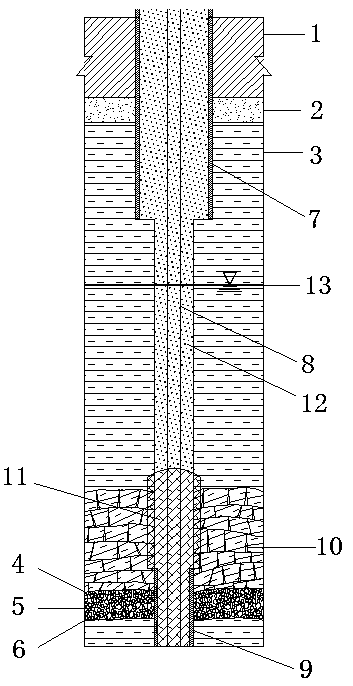

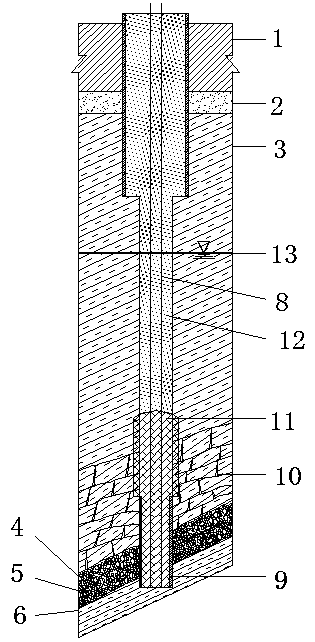

[0039] Embodiment 1, taking the steel pipe column treatment goaf construction method successfully applied to the construction site on the southeast side of Xuzhou Huaihai Art Exhibition and Trading Center as an example, the technical details of this construction method are introduced.

[0040] About 45 meters underground in this block is a 22-coal mined-out area, and the thickness of the original coal seam is about 1.0 meters. Drilling revealed that the core in the goaf area was broken, and the drill dropped by up to 10cm.

[0041] Such as figure 1 As shown, the structure of pile holes for goaf treatment is as follows: a φ168mm thin-walled steel pipe 1 is lowered into the soil layer 1 to protect the wall, and the hole diameter of the rock layer is φ146mm. The horizontal pile distance of each row is 2 meters, the row distance is 2 meters, and the pile holes of each row are staggered from the pile holes of the adjacent row, such as Figure 4 shown.

[0042] The seamless steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com