Comprehensive test system for harmonic reducer

A harmonic reducer and comprehensive test technology, which is applied in the direction of machine gear/transmission mechanism testing, etc., can solve the problems that cannot completely cover various tests, and achieve the effect of realistic simulation of working conditions and high test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

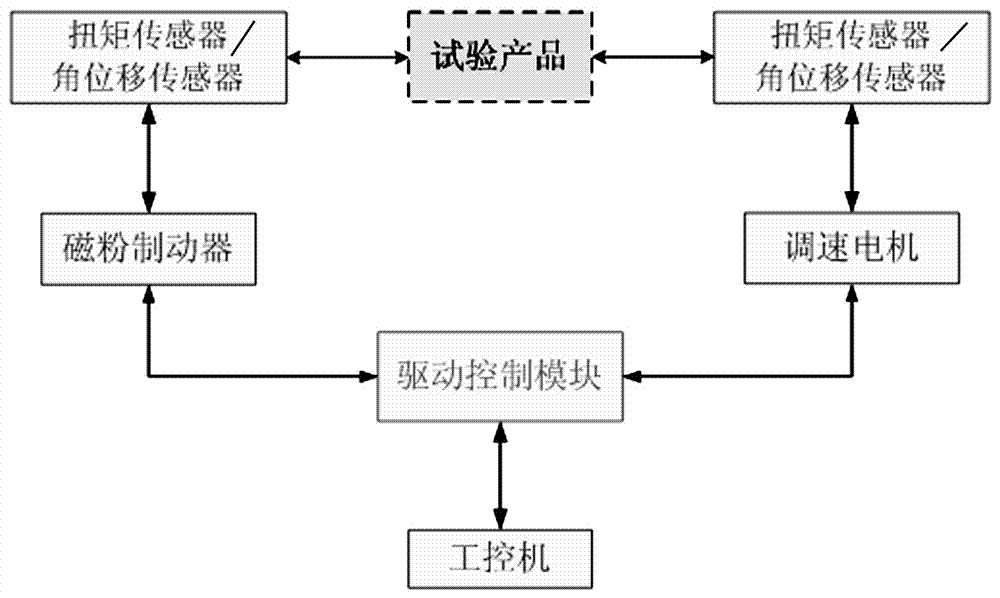

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

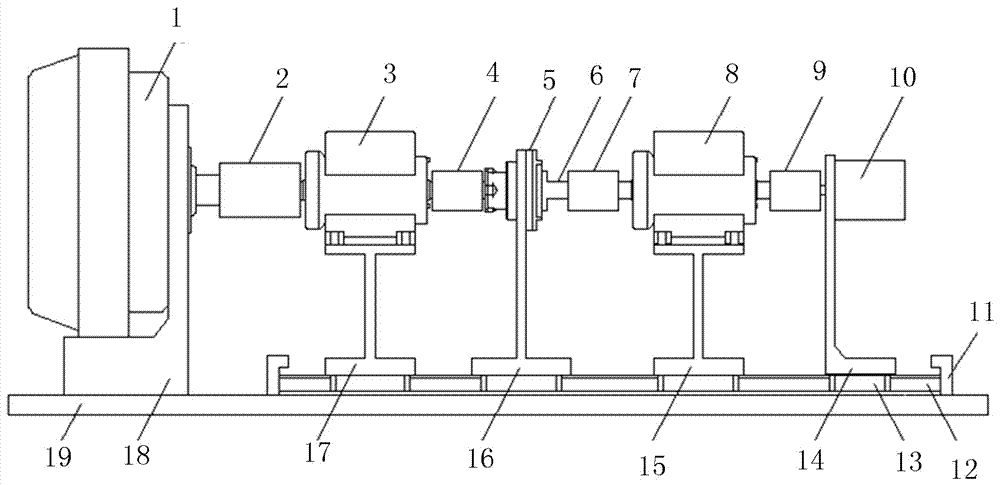

[0022] Such as figure 2 As shown, in the test related to bearing capacity, the magnetic powder brake 1 is fastened on the magnetic powder brake support 18, the magnetic powder brake support 18 is fixed on the test platform 19, and the magnetic powder brake 1 is connected with the torque sensor 1 3 through the shaft coupling 1 2 . The torque sensor I 3 is connected to the output end of the harmonic reducer 5 through the coupling II 4. The input end of the harmonic reducer 5 is connected with the connecting shaft 6, and is connected with the torque sensor ΙΙ 8 through the shaft coupling III 7, and the torque sensor ΙΙ 8 is connected with the speed regulating motor 10 through the shaft coupling IV 9. The speed regulating motor 10 is fastened on the motor support 14, and the motor support 14 is fixed on the horizontal slider 13. Described torque sensor ΙΙ 8, harmonic speed reducer 5, torque sensor Ι 3 are respectively fastened with torque sensor support ΙΙ 15, reducer support 1...

Embodiment 2

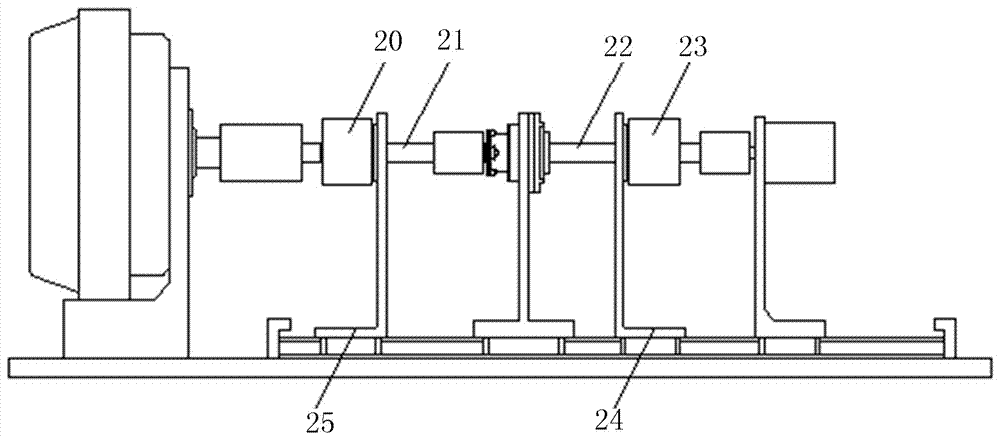

[0024] Such as image 3 As shown, in the accuracy test, only the torque sensor needs to be replaced by the photoelectric encoder, and the structure of the rest of the device remains unchanged, which can be used for the accuracy test. The specific embodiment is that the photoelectric encoder Ι 20, the photoelectric encoder Ι 23, the photoelectric encoder support Ι 25, and the photoelectric encoder support Ι 24 are respectively fixed on the horizontal slider to form a new slider unit, And get final product that link to each other with corresponding shaft coupling by connecting rod Ι 21, connecting rod Ι 22, other structures are with embodiment 1.

[0025] When the test system is working, the torque sensor collects the torque and speed at the input and output ends of the reducer in real time, and the photoelectric encoder collects the angular displacement at the input and output ends of the reducer in real time, and then transmits the measured data to the industrial computer thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com