Method for preparing hydrophobic silica aerogel cement-based heat-preservation material

A technology of hydrophobic silica and thermal insulation materials, which is applied in the field of preparation of hydrophobic silica airgel cement-based thermal insulation materials, can solve the problems of no effective methods for improvement, and achieve the effects of easy regulation of thermal insulation performance, easy molding, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

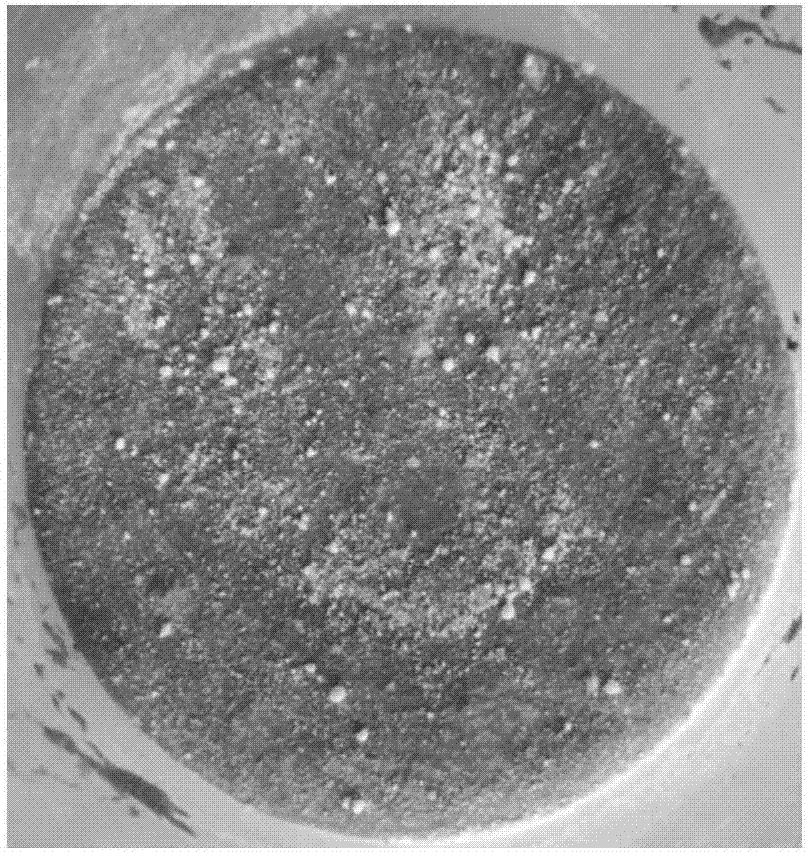

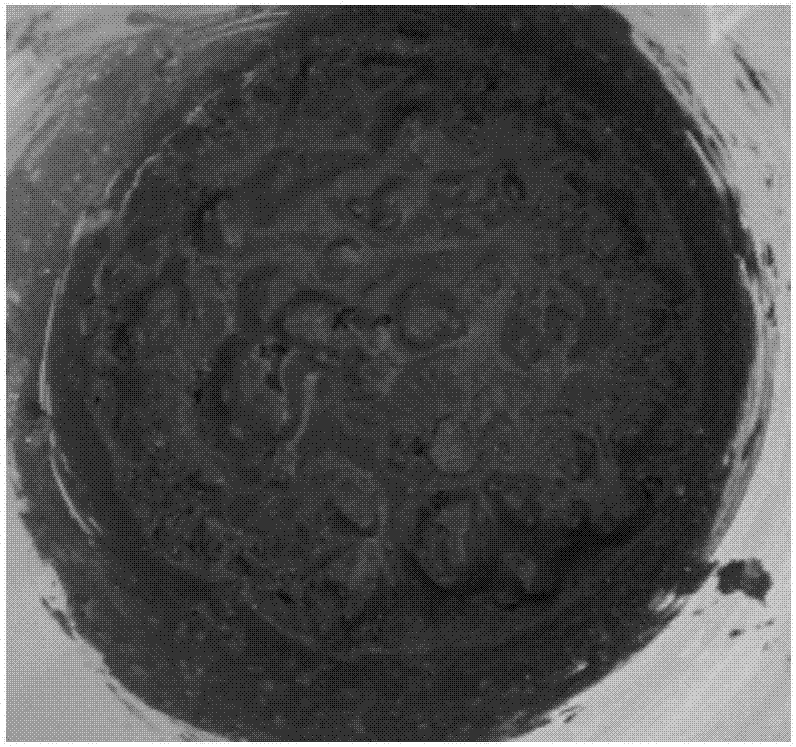

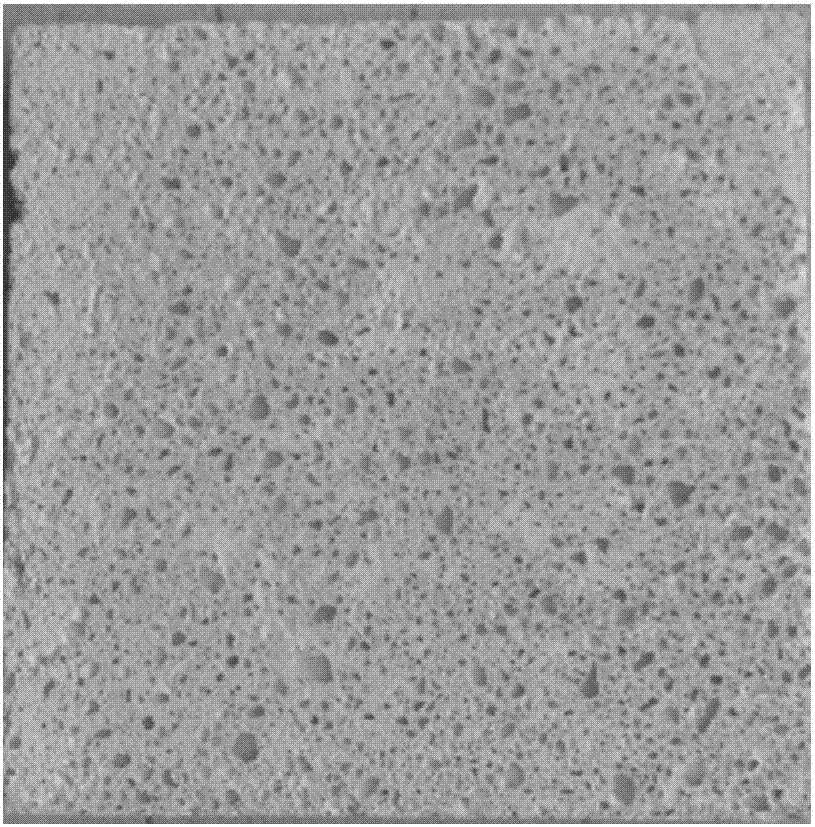

Image

Examples

Embodiment 1

[0042] (1) Add 200g of water and 6g of Span 20 into a 1L beaker, stir well to prepare a solution;

[0043] (2) Add 400g of P.O42.5R cement to the solution obtained in step (1), stir evenly, then add 8g of hydrophobic silica airgel powder, and stir until the hydrophobic silica airgel is covered by cement The slurry is infiltrated or wrapped to obtain the product, that is, hydrophobic silica airgel thermal insulation mortar.

[0044] After 28 days of mortar molding and curing, the measured thermal conductivity is 0.413W / (m·k), and the dry density is 1400kg / m 3 .

Embodiment 2

[0046] (1) Add 200g of water and 6g of Ameroxl OE-10 into a 1L beaker, stir well to prepare a solution;

[0047] (2) Add 400g of P.O42.5R cement to the solution obtained in step (1), stir evenly, then add 16g of hydrophobic silica airgel powder, and stir until the hydrophobic silica airgel is covered by cement The slurry is infiltrated or wrapped to obtain the product, that is, hydrophobic silica airgel thermal insulation mortar.

[0048] After 28 days of mortar molding and curing, the measured thermal conductivity is 0.340W / (m·k), and the dry density is 1300kg / m 3 .

Embodiment 3

[0050] (1) Add 400g of water and 6g of Span 20 into a 1L beaker, stir well to prepare a solution;

[0051] (2) Add 400g of P.O42.5R cement to the solution obtained in step (1), stir evenly, then add 24g of hydrophobic silica airgel powder, and stir until the hydrophobic silica airgel is covered by cement The slurry is infiltrated or wrapped to obtain the product, that is, hydrophobic silica airgel thermal insulation mortar.

[0052] After 28 days of mortar molding and curing, the measured thermal conductivity is 0.266W / (m·k), and the dry density is 1220kg / m 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Dry density | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com