Subzero treatment device

A cryogenic treatment and cryogenic technology, applied in the field of low temperature, can solve the problems of poor temperature control accuracy, short life, high failure rate, etc., and achieve the effects of reducing energy consumption, simplifying the structure, and reducing the incidence of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

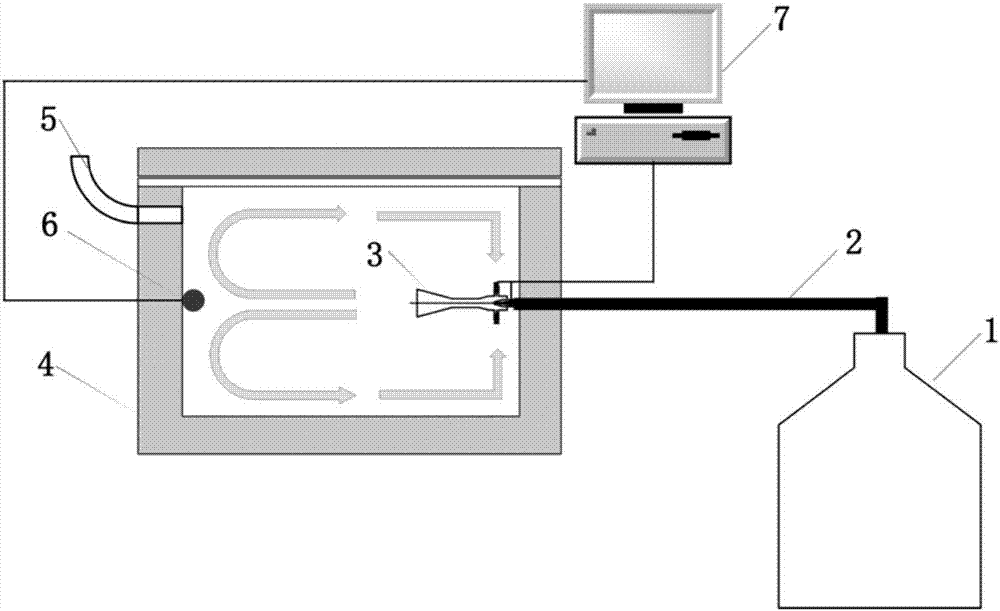

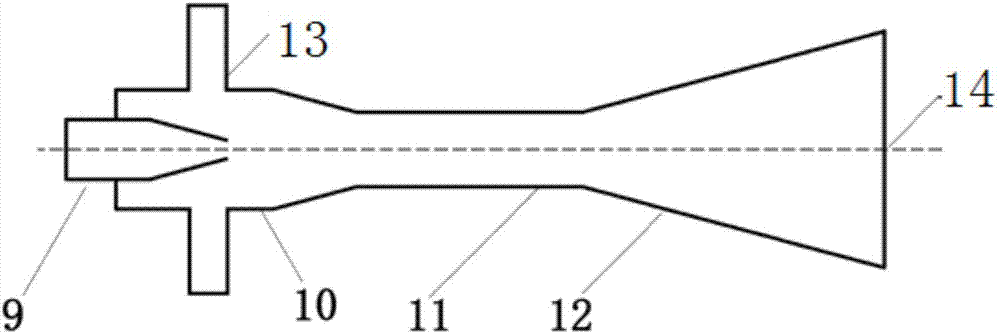

[0024] Please refer to figure 1 , a cryogenic treatment device provided in an embodiment of the present invention, comprising: a liquid nitrogen tank (1), a low-temperature infusion tube (2), a low-temperature regulating valve (3), a liquid-gas ejector (4), a cryogenic box Body (5), exhaust gas return line (6), temperature sensor (7) and controller (8). in:

[0025] The mouth of the liquid nitrogen tank (1) is connected to one end of the cryogenic infusion pipe (2), the low temperature regulating valve (3) is installed on the pipeline of the cryogenic infusion pipe (2), and the low temperature regulating valve (3) is The valve (3) is electrically connected to the controller (8), the other end of the cryogenic infusion tube (2) is connected to the liquid-gas ejector (4), and the liquid-gas ejector (4) Set in the cryogenic box (5), the side of the cryogenic box (5) opposite to the low-temperature infusion tube (2) is connected with the exhaust gas return line (6) , the temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com