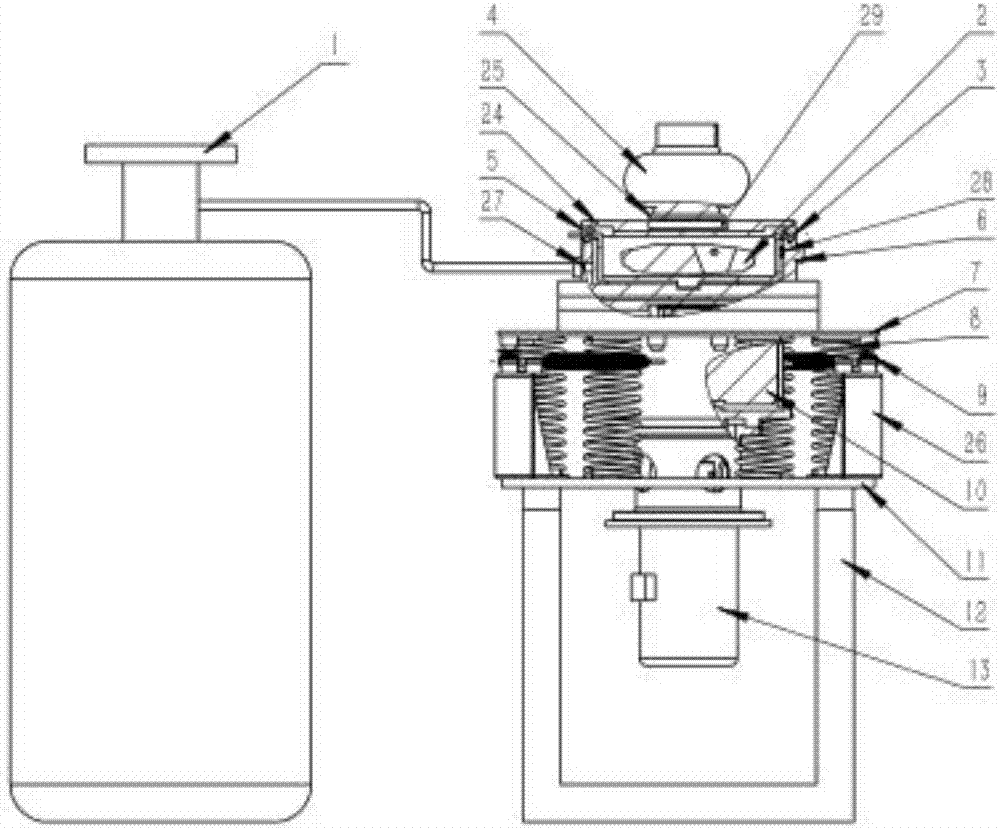

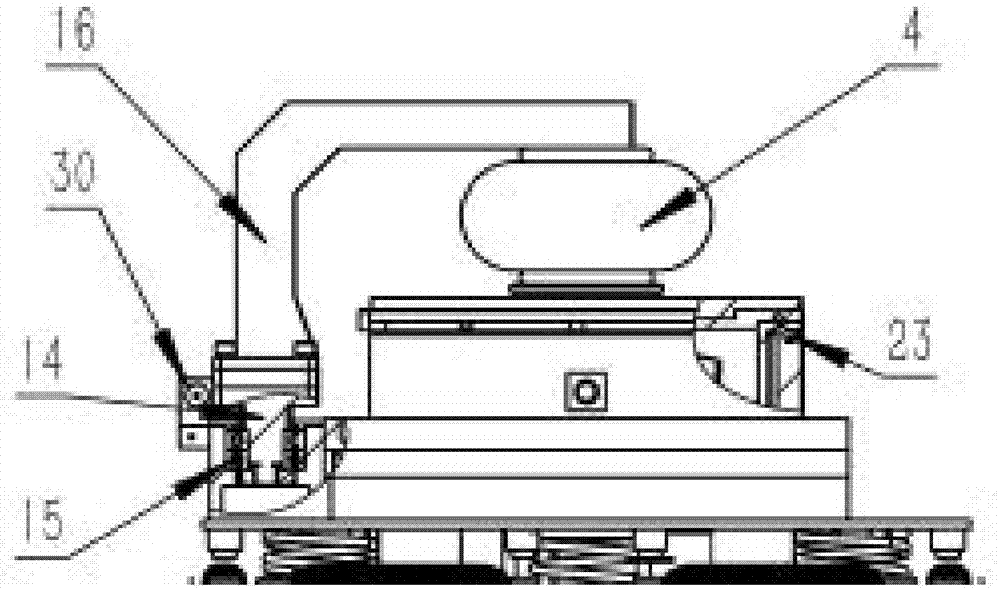

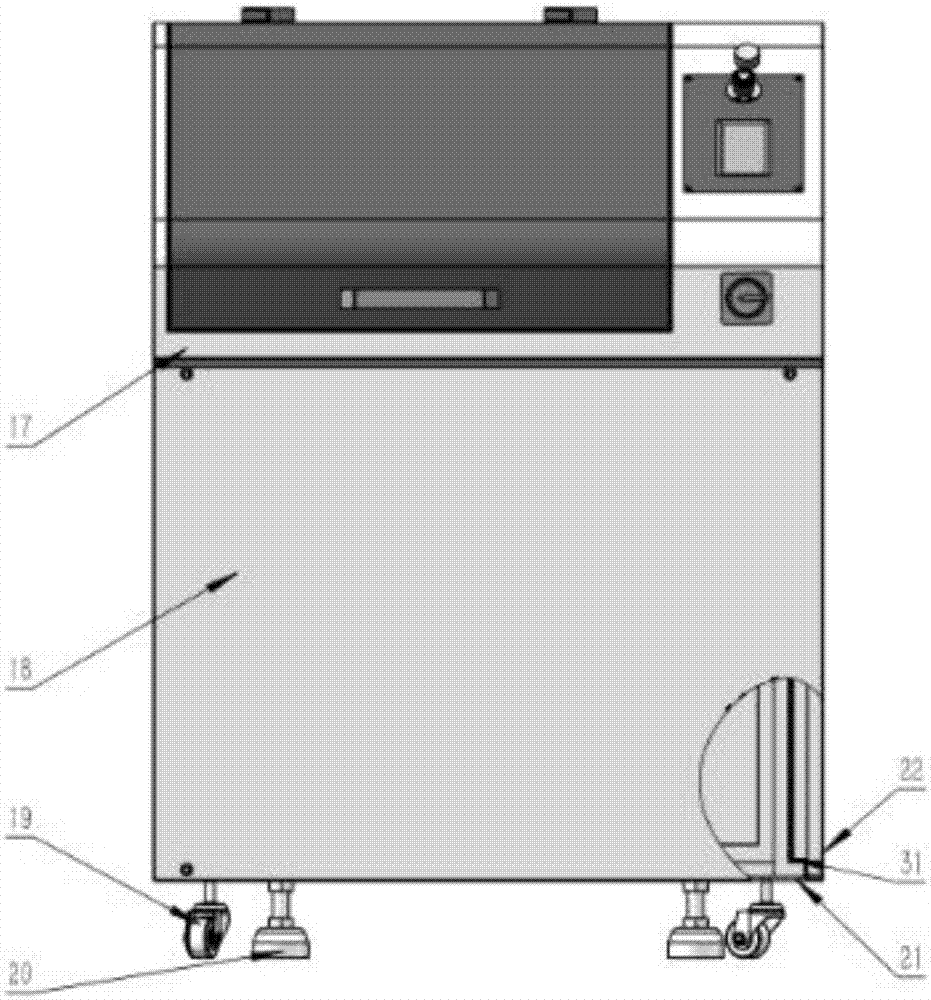

Automatic control and continuous freezing grinding machine

A freeze-grinding and grinding device technology, applied in the grinding field, can solve the problems of low utilization rate of coolant, inability to continuously freeze-grind, limited scope of application, etc., and achieve the effect of ensuring safe operation, clear structure and high grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] Example 1 Carried out grinding experiment at -170°C

[0072] Grinding candied dates food 500g. Food size: 10-20mm; Grinding box volume: 1200ml; Grinding component mass: 16kg; Spacer material: PTFE; Eccentric wheel mass: 11kg; Spiral tube material: PTFE; The time is 40min, the grinding speed is 1300r / min, and the size of the product obtained by grinding for 2min: ≤0.01mm.

Embodiment 2

[0073] Embodiment 2 Carry out -170 ℃ grinding experiment

[0074] Grind 500ml glutinous rice balls. Food size: 10-20mm; grinding box volume: 1200ml; grinding component mass: 16.5kg; spacer material: PTFE, eccentric wheel mass: 12kg; spiral tube material: PTFE, freezing medium: liquid nitrogen; The freezing time is 20 minutes, the grinding speed is 1350r / min; the size of the product obtained by grinding for 2 minutes: ≤0.01mm.

Embodiment 3

[0075] Embodiment 3 carries out -100 ℃ grinding experiment

[0076] Grind jujube and walnut 2kg. Food size: 10-20mm, grinding box volume: 3000ml; grinding component mass: 17.5kg; spacer material: PTFE; eccentric wheel mass: 16kg; spiral tube material: PTFE; freezing medium: liquid nitrogen; The freezing time is 20 minutes, the grinding speed is 1300r / min, and the grinding time is 2 minutes to obtain the product size: ≤0.07mm.

[0077] It can be seen from Examples 1 to 3 that the grinding temperature of the frozen grinder of the present invention can be reduced to -170°C, the amount of raw materials to be ground is greatly increased, and the grinding efficiency is high. It can also be ground after 2 minutes for tough raw materials. A small particle size product is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com