Tray stacking machine

A technology of a piling machine and a sliding block is applied in the field of agricultural machinery, which can solve the problems of increasing labor costs, and achieve the effect of saving labor costs, facilitating industrial production, and reducing labor requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further illustrate the technical means adopted by the present invention and the technical effects achieved, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

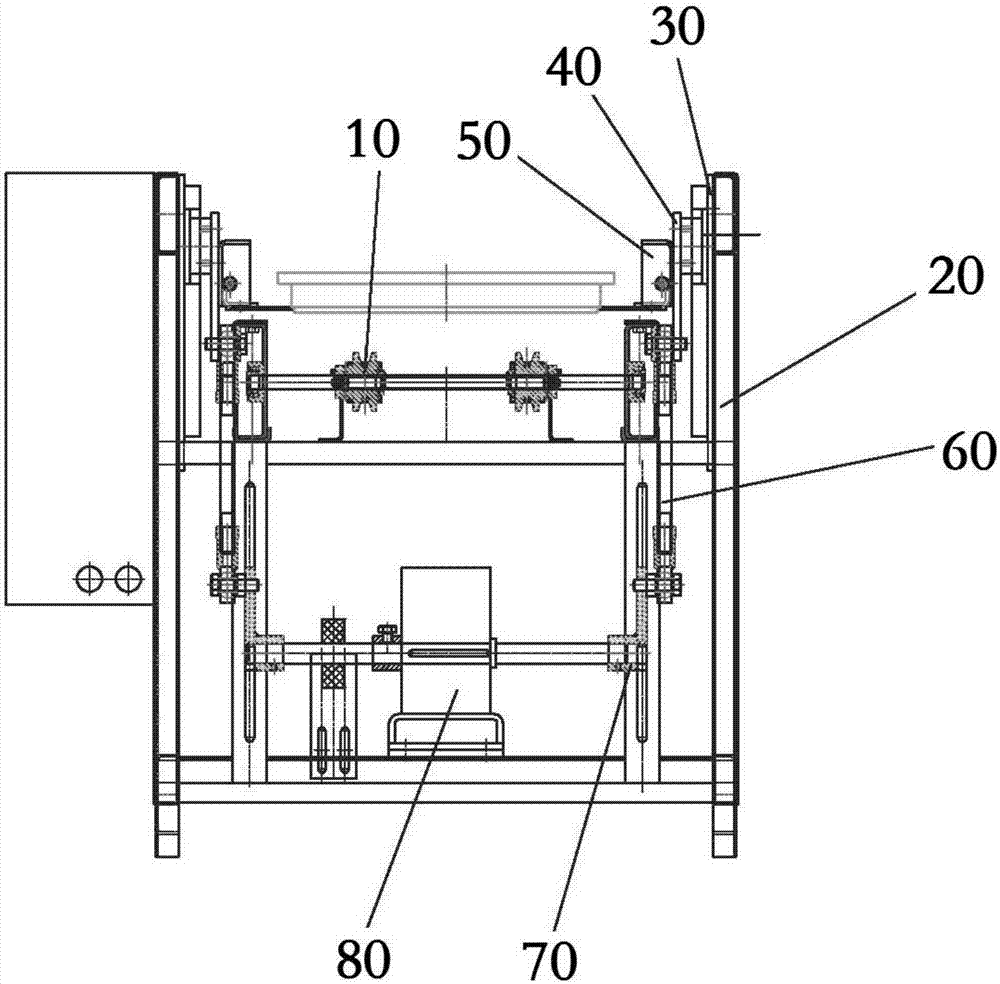

[0028] A kind of base plate machine of the present invention, refer to figure 1 , which includes a conveyor belt 10, a fixed baffle 20, a slider guide rail 30, a slider 40, a support baffle 50, a connecting rod 60, a connecting crankshaft 70, and a motor 80. Wherein the conveyor belt 10 is arranged symmetrically and runs synchronously, and the fixed baffles 20 are arranged on the outsides of both sides of the conveyor belt 10 . The slider guide rails 30 are vertically fixed on the fixed baffles 20 on both sides, and are arranged symmetrically. The slider 40 is arranged on the slider guide rail 30 , it matches with the slider guide rail 30 , and can slide up and down on the slider guide rail 30 .

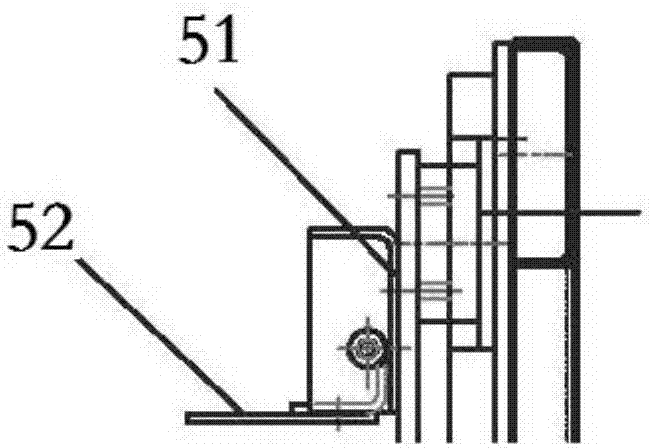

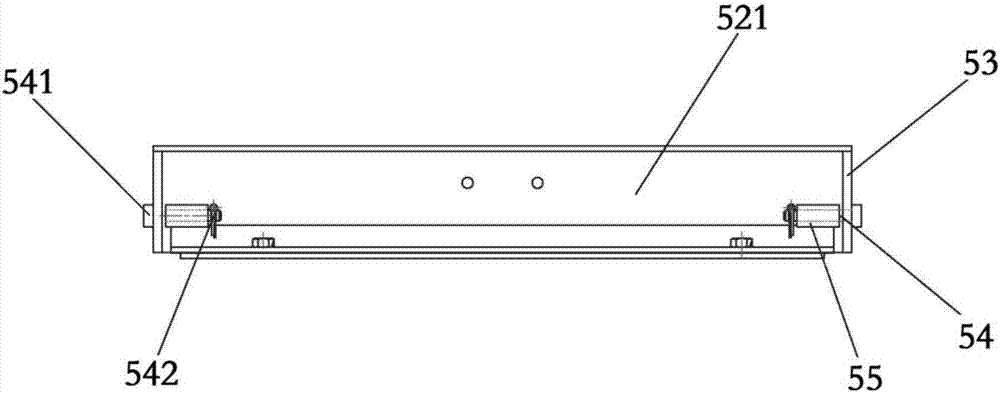

[0029] refer to figure 2 The support baffle 50...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap