Laminated spiral type dewatering machine capable of inputting mud from tail end

A dehydrator and screw technology, which is applied in water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, sludge treatment, etc., can solve the problems of overall assembly impact, high processing difficulty and low precision, etc. Achieve the effect of low cost, low processing difficulty and high filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

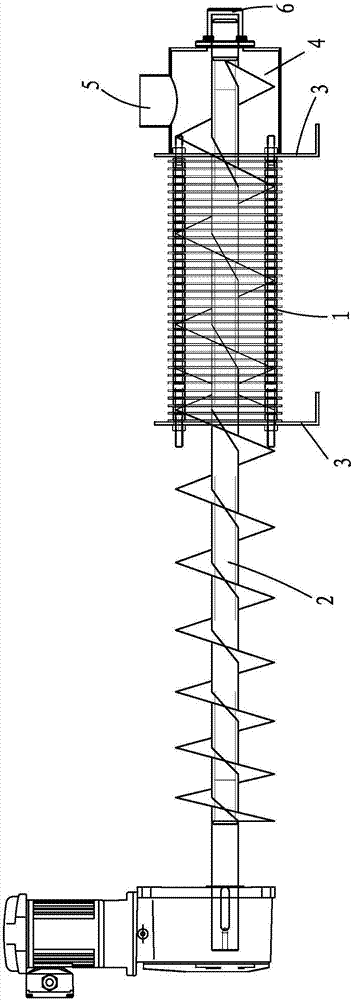

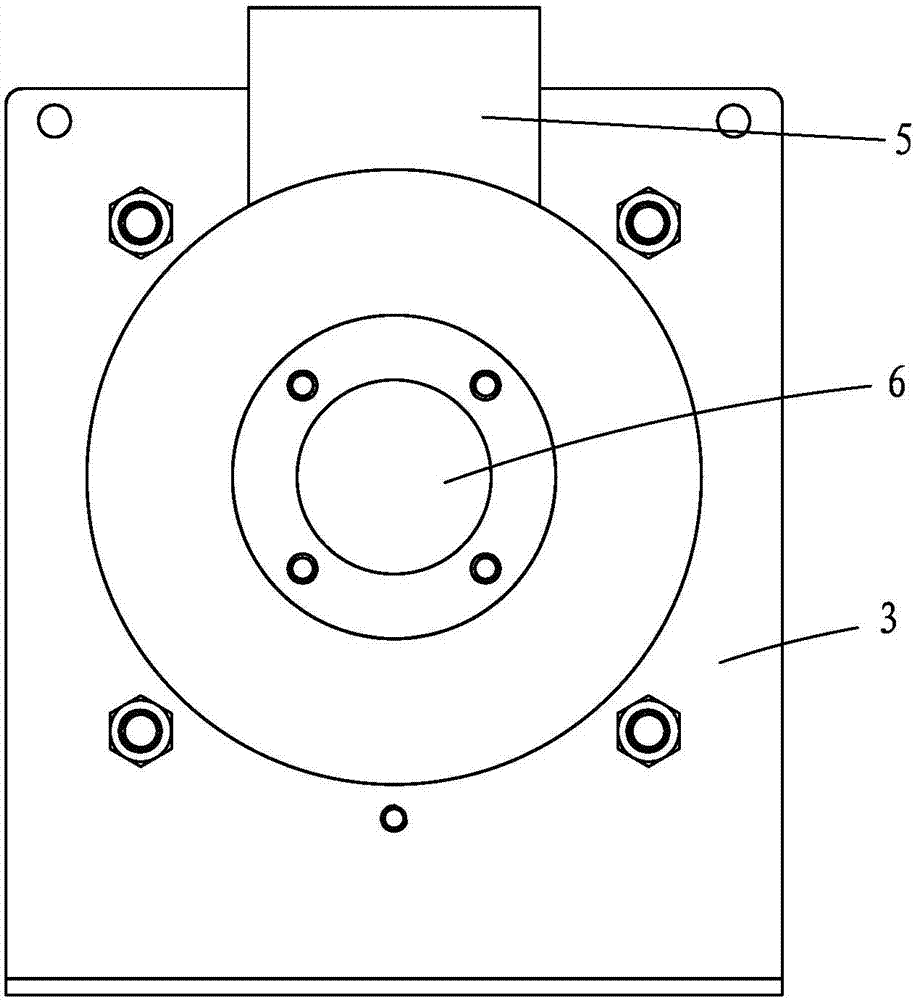

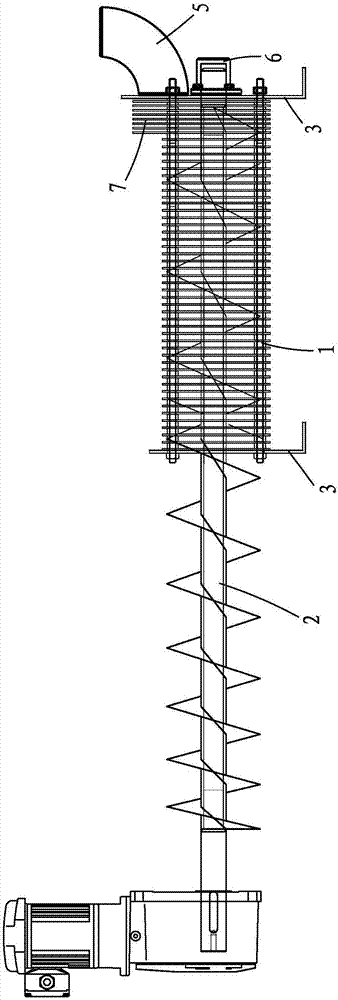

[0024] like Figure 3 to Figure 6 As shown, a stacked spiral dehydrator with mud feeding at the tail end, including a solid-liquid separation part 1 with fixed rings and movable rings staggered, and a screw shaft 2 passing through the solid-liquid separation part 1, located in the dehydration The mud outlet (not shown) at the head end of the machine main body, the mud inlet 5 at the tail end of the dehydrator main body; the solid-liquid separation part 1 is supported by a plurality of support plates 3; the tail end of the screw shaft 2 is supported by a The shaft sleeve 6 is supported; the shaft sleeve 6 is fixedly arranged on the support plate 3 at the tail end of the main body of the dehydrator; the mud inlet 5 is located on the support plate 3 at the main end of the dehydrator and above the shaft sleeve 6; The mud inlet 5 is connected to the solid-liquid separation part 1 through a mud inlet structure 7 .

[0025] The mud inlet structure 7 includes a complex fixed ring 71 ...

no. 2 example

[0027] like Figure 7 to Figure 10 As shown, the difference from the first embodiment is that the tail end of the double screw shaft is used to enter the stacked spiral dehydrator.

[0028] The mud inlet structure part in the present invention can also be filtered, and the length of the mud inlet structure is shorter than the length of the prior art sleeve, therefore, the dehydrator with the same length screw shaft has high filtration efficiency in the present invention; no additional welding of the sleeve is required, The processing difficulty is small; the cost is low.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com