A kind of cationic modifier for textile pretreatment and its synthetic method

A technology of cationic modifier and synthesis method, which is applied in the field of cationic modifier for textile pretreatment and its synthesis. It can solve the problems of small molecular weight, insufficient adsorption force of cloth surface, damage to fiber performance, etc., and achieve good uniformity and uniformity. The effect of good degree and good fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

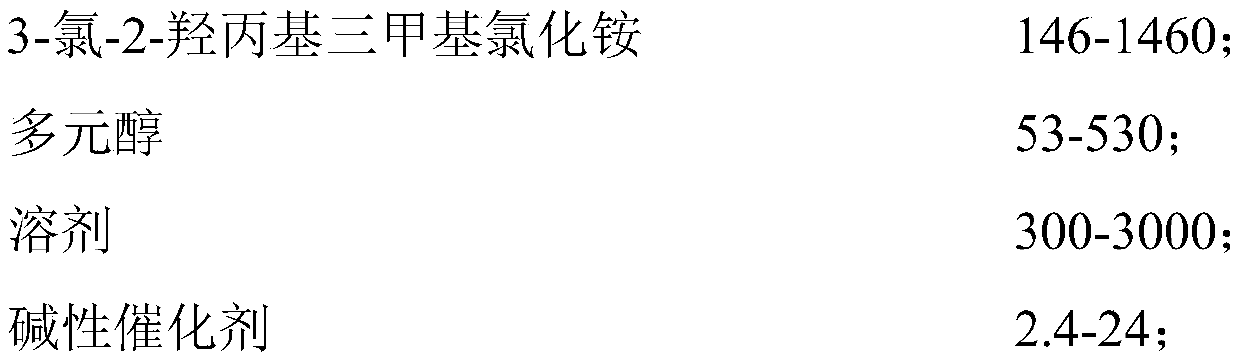

[0033] In the first step, add materials in the three-necked flask according to the following ratio:

[0034]

[0035] Start stirring, heat to 60°C and react for 8 hours, then cool down for use.

[0036] In the second step, add 250 parts of diphenylmethane diisocyanate into the three-necked flask, then add 100 parts of the product reacted in the first step, add the metal catalyst dibutyltin dilaurate and heat to 80°C to initiate the reaction. After 4 hours of reaction, Then add 100 parts of the reaction product of the first step, and continue to react for 4 hours.

[0037] The third step is to dilute and stir evenly according to the following ratio:

[0038]

Embodiment 2

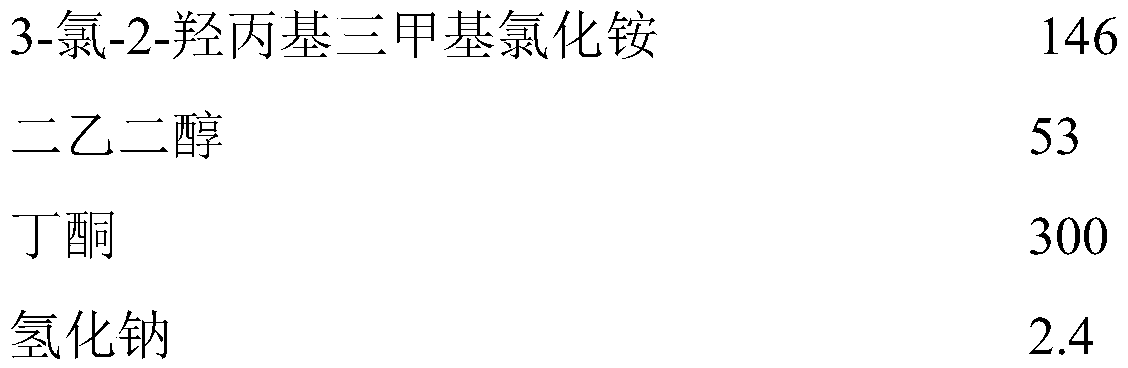

[0040] In the first step, add materials in the three-necked flask according to the following ratio:

[0041]

[0042] Start stirring, heat to 80°C and react for 12 hours, then cool down for use.

[0043] In the second step, add 400 parts of toluene diisocyanate into the three-necked flask, then add 150 parts of the product of the first step reaction, add a metal catalyst and heat to 80°C to initiate the reaction, and after 4 hours of reaction, add 150 parts of the first step reaction product part, continue to react for 4 hours.

[0044] The third step is to dilute and stir evenly according to the following ratio:

[0045]

Embodiment 3

[0047] In the first step, add materials in the three-necked flask according to the following ratio:

[0048]

[0049] Start stirring, heat to 70°C and react for 5 hours, then cool down for use.

[0050] In the second step, add 250 parts of diphenylmethane diisocyanate and 150 parts of methyl isocyanate in the three-necked flask, then add 100 parts of the product of the first step reaction, add metal catalyst dibutyltin dilaurate and heat to 80 ℃ to initiate the reaction, after 4 hours of reaction, add 100 parts of the reaction product of the first step, and continue the reaction for 4 hours.

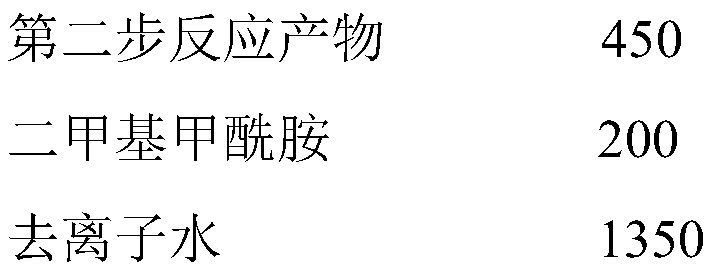

[0051] The third step is to dilute and stir evenly according to the following ratio:

[0052]

[0053] The application comparison report of the cationic modifier prepared in each of the above examples and the international leading Japanese product of the same kind, AROMAFIX PT, is as follows:

[0054] Test process:

[0055] ① Pretreatment

[0056] Cationic Modifier X%(O.W.F)

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com