A kind of hydrophilic strong alkali resistant color fixing agent and preparation method thereof

A technology of strong alkali resistance and color-fixing agent, which is applied in dyeing, textiles and papermaking, etc. It can solve the problems of large influence of fabric color change, general color fixing effect, and decline of color fixing effect, so as to improve the color fastness of fabrics, Reduce the generation of floating color, color fixing effect and excellent effect of alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

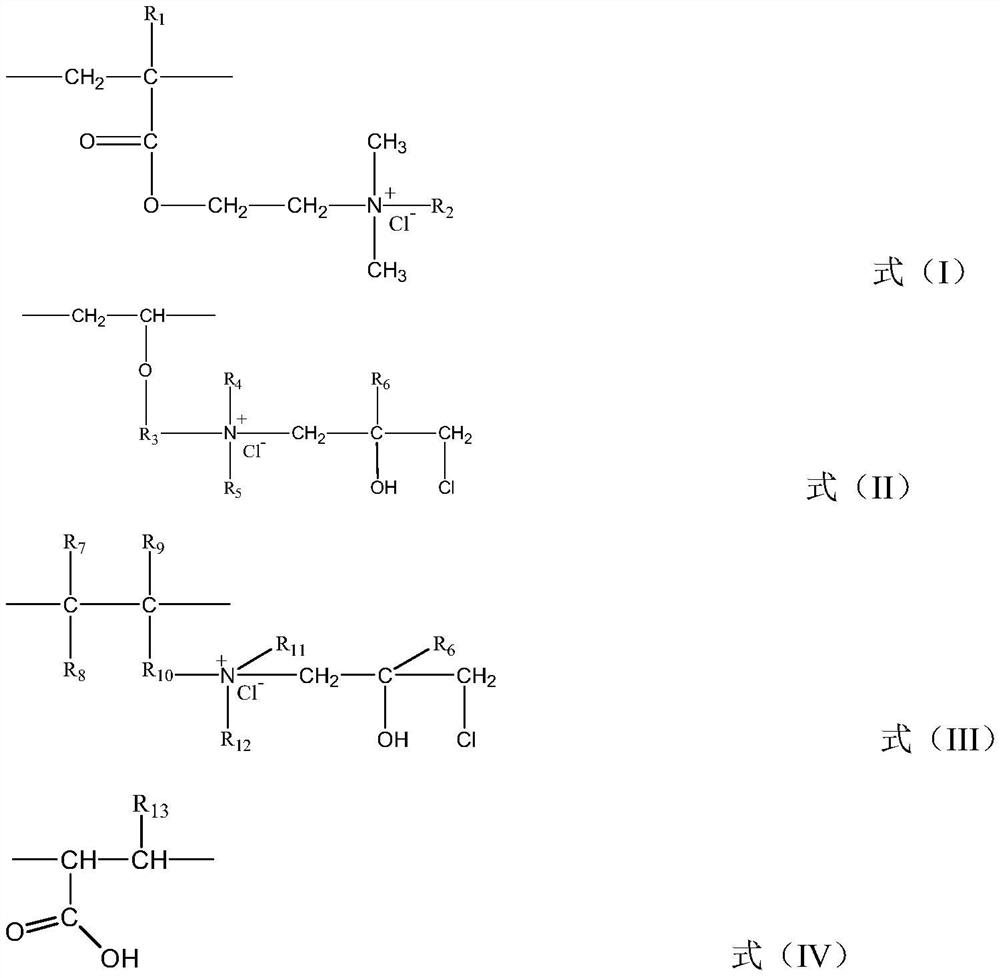

[0054] In a preferred embodiment of the present invention, the present invention provides a kind of preparation method of above-mentioned hydrophilic strong alkali resistant color fixing agent, this method comprises the following steps:

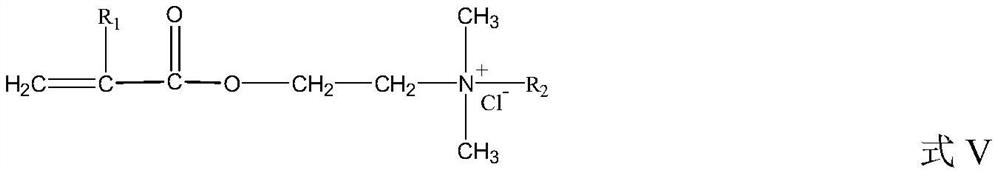

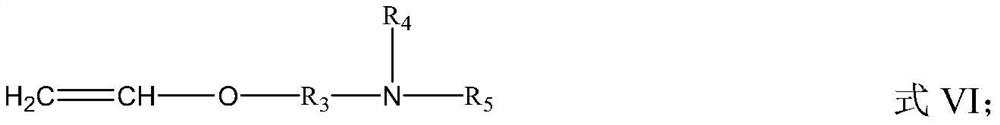

[0055] 1) The (meth)acryloxy quaternary ammonium salt cationic monomer represented by a molar formula (V), the amino-containing vinyl ether monomer represented by b molar formula (VI), and the c molar formula (VII) represented The enamine monomer, the unsaturated carboxylic acid monomer represented by d mole formula (VIII) and water (preferably deionized water) are added into the reactor for stirring. Stirring is preferably carried out at 40-80°C for 10-20 minutes. In the above monomer mixture, preferably based on the total weight of the monomers, 10-25% by mass of an acid agent and 20-60% by mass of water are optionally added. The above-mentioned acid agent is preferably a strong acid, more preferably an inorganic strong acid, such as hydro...

Embodiment 1

[0079] Add 30g of acryloyloxyethyltrimethylammonium chloride (80%; M=193.67; n=0.1239mol), 8g of 2-(diethyl Amine) ethanol vinyl ether (M=143; n=0.05594mol), 4.6g N-ethylmethylacrylamine (M=99.17; n=0.04638mol), 10g crotonic acid (M=86.09; n=0.1162mol ), 11g hydrochloric acid (37%; M=36.46; n=0.1116mol) and 26.4g deionized water, after stirring at 60°C for 10min, start to add 1% ammonium persulfate aqueous solution dropwise, after 1.5h dropwise, heat up to 80°C , keep warm for 2.5h, then lower the temperature to 40°C, adjust the pH value to 7-8 with NaOH, add 10g of epichlorohydrin (M=92.52; n=0.1081mol) dropwise, finish adding dropwise for 1.5h, and keep warm for 3h. Obtain hydrophilic and alkali-resistant color fixing agent 1. The application effect is shown in Table 1 and Table 2. The weight-average molecular weight of the hydrophilic and alkali-resistant color fixing agent 1 is 35,000.

Embodiment 2

[0081] Add 37g of methacryloyloxyethyltrimethylammonium chloride (75%; M=207.7; n=0.1336mol), 10g of 2-(di Ethylamine) ethanol vinyl ether (M=143; n=0.06993mol), 5g N-methyl-2-methylallylamine (M=85.15; n=0.05872mol), 8g crotonic acid (M= 86.09; n=0.09293mol), 12g hydrochloric acid (37%; M=36.46; n=0.1218mol) and 16g deionized water, after stirring at 70°C for 10min, start to add 1% ammonium persulfate aqueous solution dropwise, and the dropwise addition is completed after 1h. Raise the temperature to 75°C, keep it warm for 3h, then lower the temperature to 50°C, adjust the pH value to 7-8 with NaOH, add 12g of epichlorohydrin (M=92.52; n=0.1297mol) dropwise, finish adding dropwise for 2h, keep warm for 2.5h . Obtain hydrophilic strong alkali resistant color fixing agent 2. The application effect is shown in Table 1 and Table 2. The weight-average molecular weight of the hydrophilic and alkali-resistant color fixing agent 2 is 67,000.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com