Permanent magnet tuning mass damping device used for bridge expansion joint damage control

A technology of tuning mass damping and disease control, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as expansion joint damage, reduce the probability of distortion damage, and achieve the effect of simple and flexible installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

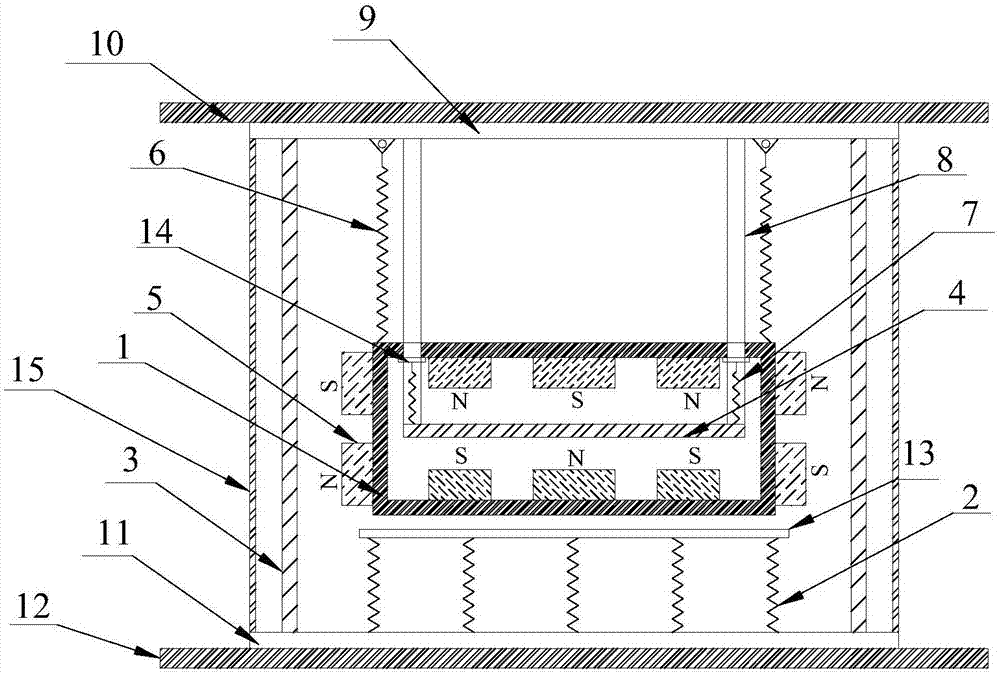

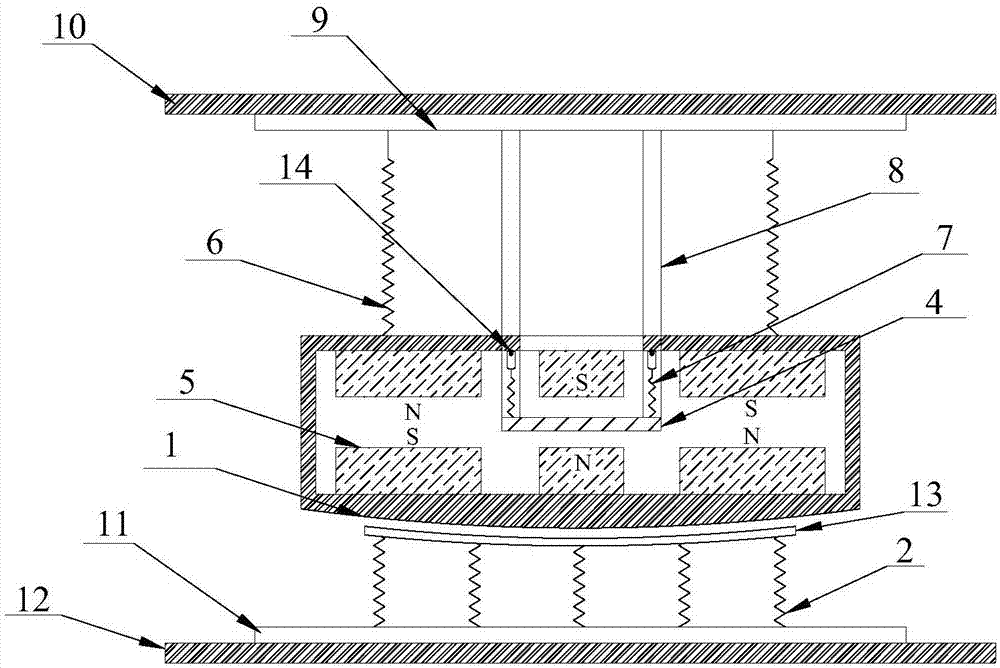

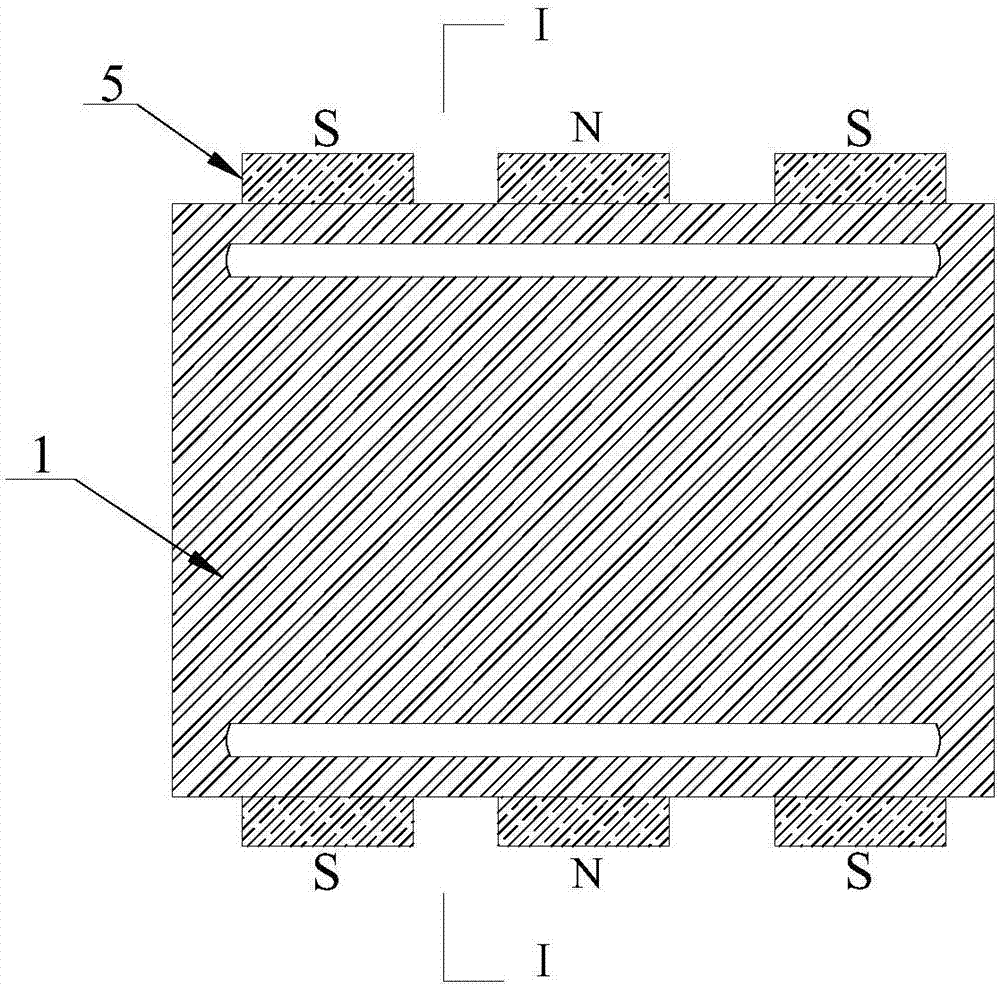

[0033] The upper fixed plate 9 of the damping device is connected to the top plate 10 at the end of the box girder, and the lower fixed plate 11 is connected to the bottom plate 12 of the box beam; The permanent magnet 5 is installed inside and outside the mass block 1 to form a whole, and is hinged to the upper fixed plate 9 through the spring II6; The top of the casing 8 is bolted to the upper fixing plate 9; the outer copper plate 3 and the magnetizer 15 are located outside the mass block 1, and the upper and lower ends of the outer copper plate 3 and the magnetizer 15 are respectively consolidated with the upper fixing plate 9 and the lower fixing plate 11 The curved plate 13 is located below the mass block 1, one end of the spring I2 is fixed to the lower fixed plate 11, and the other end is consolidated with the curved plate 13.

[0034] In order to prevent the mass block from vibrating vertically, the inner copper plate is vertically in contact with the permanent magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com