Phase change heat storage header type condensation radiant panel

A phase-change heat storage and radiant panel technology, which is applied in the heating method, heat storage equipment, heat exchanger type, etc., can solve the heat loss, affect the operation efficiency of the air source heat pump system in winter and indoor thermal comfort, and cannot take into account the summer. Air conditioning and refrigeration problems, to achieve the effect of reducing resistance, slowing down the phenomenon of hot lines, reducing energy consumption and energy loss in transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, and the described specific embodiments are only for explaining the present invention, and are not intended to limit the present invention.

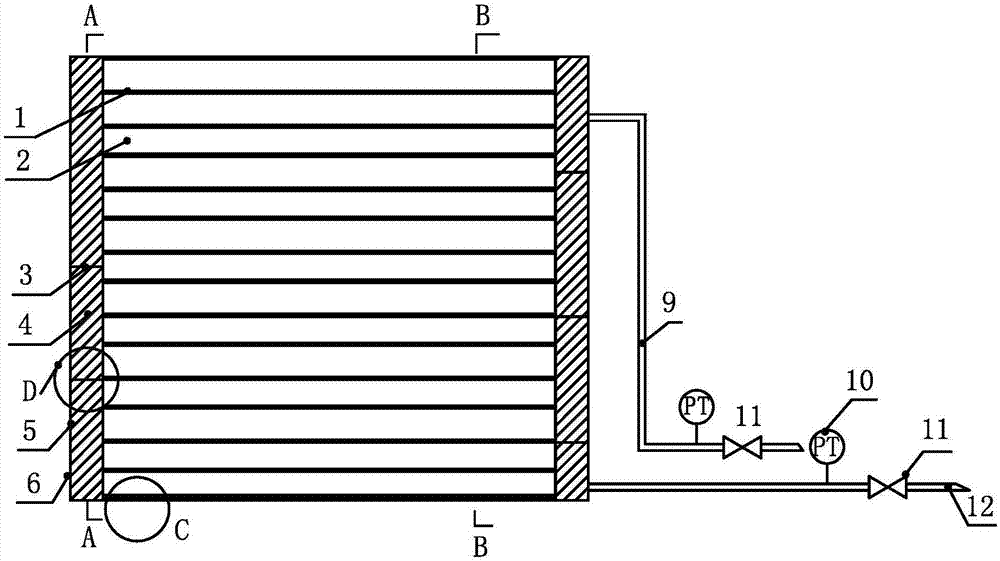

[0021] As shown in Figure 1(a), a phase-change heat storage collector-type condensing radiant panel proposed by the present invention includes a heat supply pipeline and a header-type radiant panel, and the heat supply pipeline includes a heat supply dry pipe 9 and heat recovery main pipe 12, the heat supply main pipe 9 and the heat recovery main pipe 12 are equipped with temperature and pressure sensors 10 and control valves 11; Between the heat recovery dry pipes 12 .

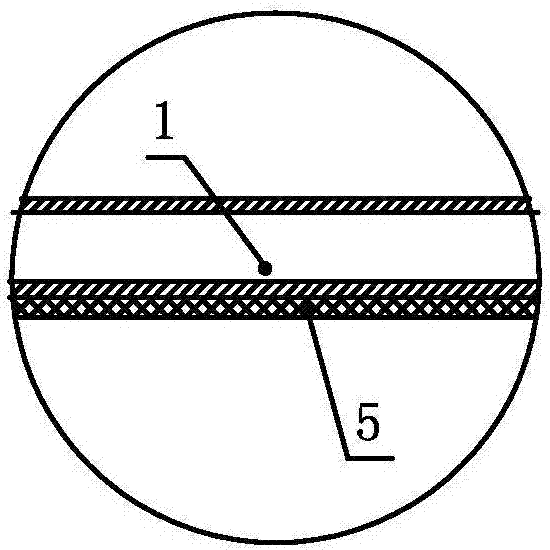

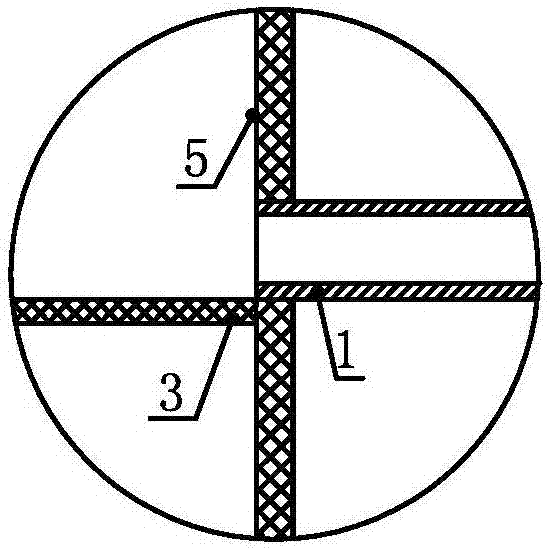

[0022] As shown in Figure 1(a), the header-type radiant panel includes a galvanized steel plate shell 5, and the two ends of the galvanized steel plate shell 5 are separated by galvanized steel plates to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com