Organic light-emitting device and light extraction assembly thereof

An organic light-emitting device and light-extracting layer technology, which is applied in the manufacturing of electric solid-state devices, semiconductor devices, semiconductor/solid-state devices, etc., can solve the problems affecting the life of OLED devices and the limited improvement of OLED light-extraction efficiency, and achieve excellent luminous efficiency. , Good blocking water and oxygen, long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

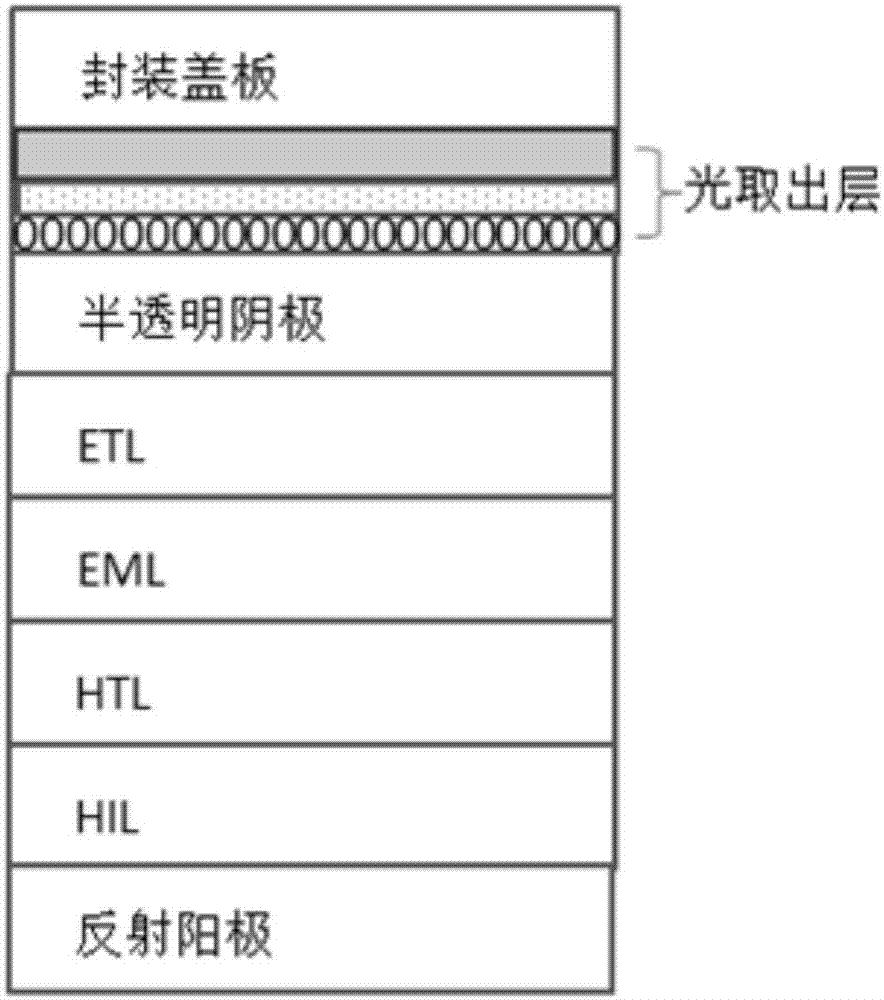

[0033] This embodiment is an organic light-emitting device, and its structural schematic diagram is as follows figure 1 As shown, the light extraction components used include:

[0034] An ITO substrate provided with a reflective anode;

[0035] A hole injection layer (HIL) deposited on an ITO substrate;

[0036] a hole transport layer (HTL) deposited over the hole injection layer;

[0037] An emissive layer (EML) deposited on top of the hole transport layer;

[0038] An electron transport layer (ETL) deposited on top of the emissive layer;

[0039] a translucent cathode deposited on top of the electron transport layer;

[0040] A light extraction layer deposited on the translucent cathode, and an encapsulation cover plate on the light extraction layer.

[0041] The above-mentioned light extraction layer includes:

[0042] The first light extraction layer deposited on the translucent cathode is made of spherical molecular material C60;

[0043] The second light extractio...

Embodiment 2

[0058] This embodiment is an organic light-emitting device, its structure and preparation method are similar to Embodiment 1, the difference is that its light extraction layer includes:

[0059] The first light extraction layer deposited on the translucent cathode is made of spherical molecular material C70;

[0060] The second light extraction layer deposited on the first light extraction layer is made of planar organic molecule TPBI and inorganic metal oxide V 2 o 5 , where the inorganic metal oxide V 2 o 5 The doping ratio is 90%;

[0061] The third light extraction layer deposited on the second light extraction layer is made of inorganic metal oxide WO 3 .

Embodiment 3

[0063] This embodiment is an organic light-emitting device, its structure and preparation method are similar to Embodiment 1, the difference is that its light extraction layer includes:

[0064] The first light extraction layer deposited on the translucent cathode is made of spherical molecular materials, specifically C70 and C60 with a weight ratio of 1:1;

[0065] The second light extraction layer deposited on the first light extraction layer is made of planar organic molecule mCP and inorganic metal oxide WO 3 , where the inorganic metal oxide WO 3 The doping ratio is 10%;

[0066] The third light extraction layer deposited on the second light extraction layer is made of inorganic metal oxide WO 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com