Water mist dust removal system

A dust removal system, water mist technology, applied in the direction of dispersed particle separation, chemical instruments and methods, combined devices, etc., can solve the problems of high energy consumption, difficult dust removal, low dust removal efficiency of dust collectors, etc., to reduce operating costs, The effect of saving consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

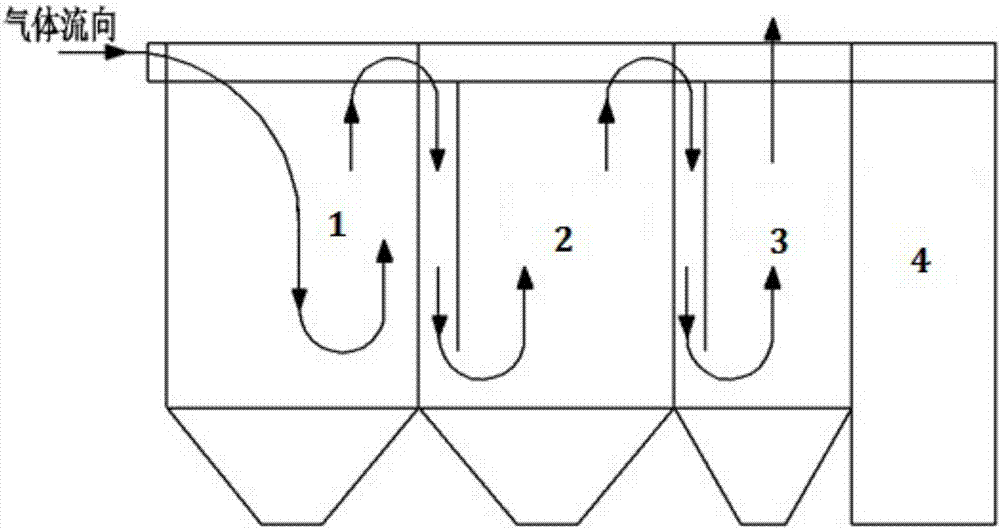

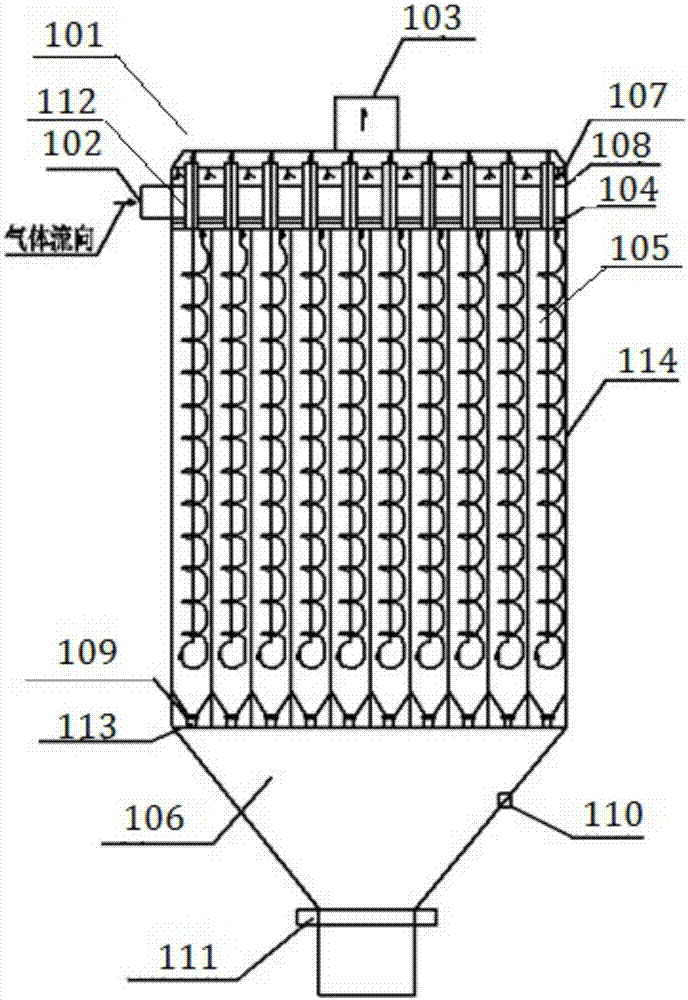

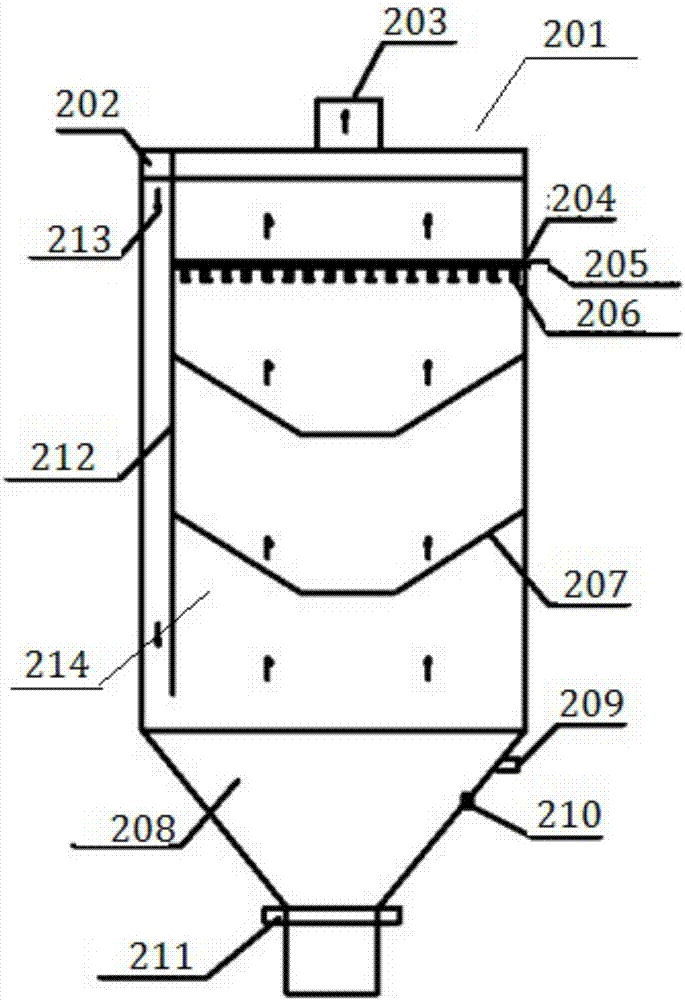

[0038] An energy-saving water mist dedusting system is disclosed in the embodiment. Through structural design, the system comprehensively utilizes the principles of centrifugal separation and water mist dedusting, adopts hierarchical settings, and is respectively equipped with a centrifugal separation device, a water mist dedusting device, and a demisting device. Humid (saturated), high temperature (not higher than 130°C) gas flows through each area in turn, and the large particles and fine particles of dust in the gas are sequentially removed under the action of different principles of gravity centrifugal separation, water film dust removal, and folding plate defogging. and moisture, to achieve a dust removal rate of more than 99% in high-temperature, high-humidity dusty gas, and clean and thorough separation of dust, gas, and water. The syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com