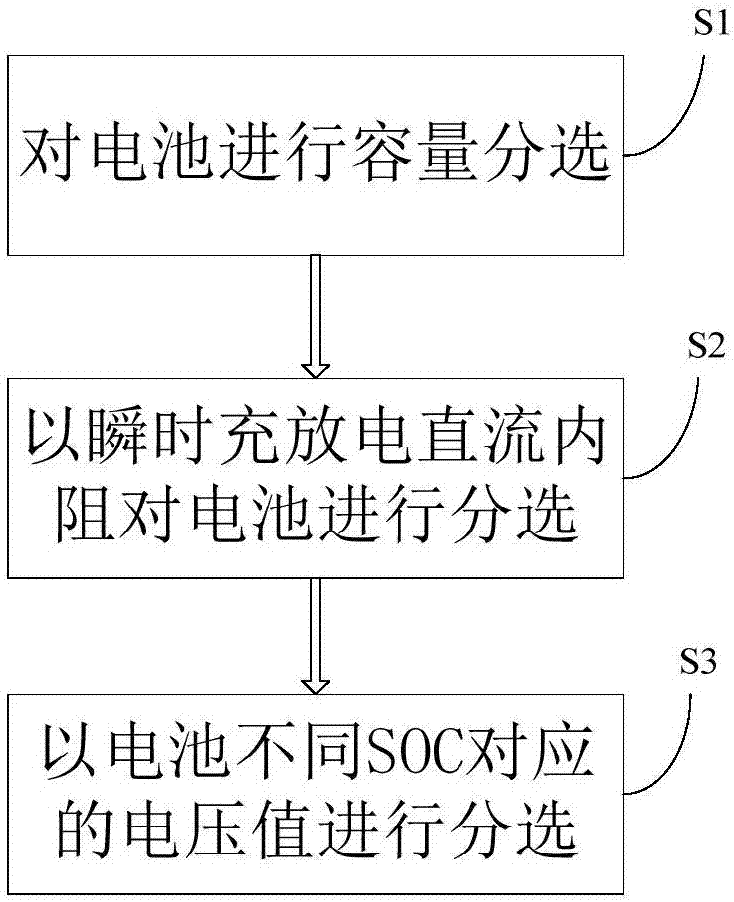

Sorting method of lithium ion power batteries

A power battery, lithium-ion technology, applied in the field of battery detection and sorting, can solve the problems of capacity limitation, inconsistency can not be eliminated, cycle life less than 200 times, etc., to reduce costs, efficient power supply, increase cycle life and charge and discharge performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

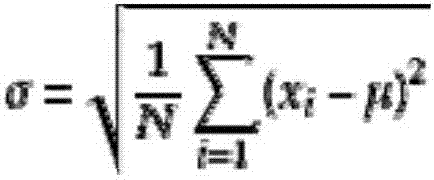

[0053] Specifically, the following uses lithium iron phosphate batteries as an example to introduce the method for sorting lithium ion power batteries of the present invention.

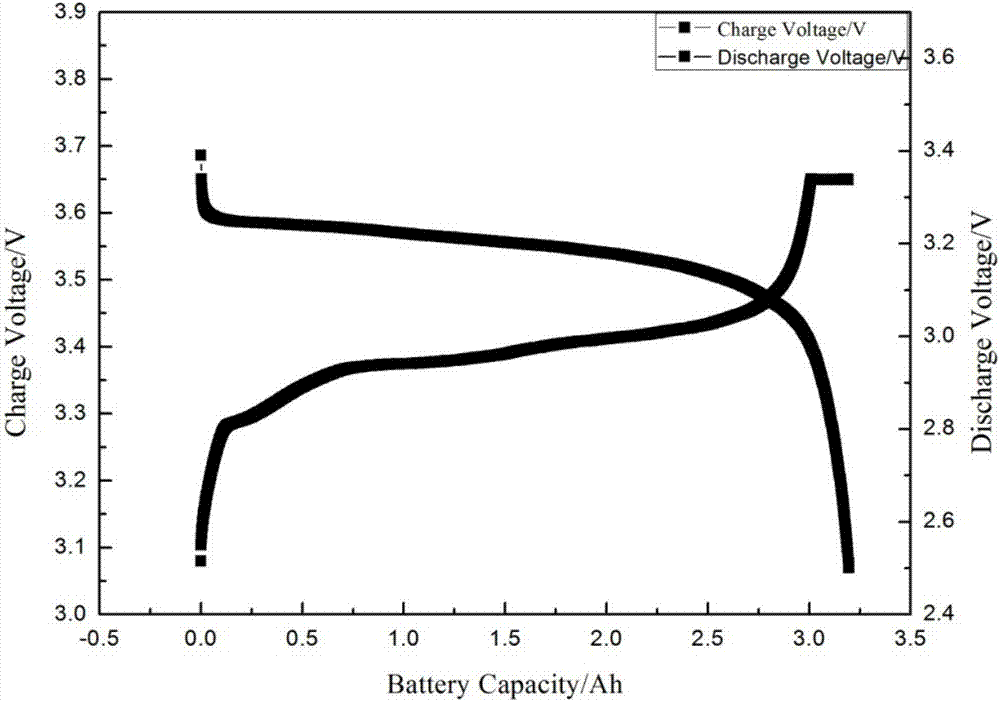

[0054] (1) Prepare one hundred 26650 lithium iron phosphate batteries with a rated capacity of 3Ah and a nominal voltage of 3.2V. Place the batteries in an environment of 25℃, 1 standard atmosphere, and 50% relative humidity, and keep them until the surface temperature of the battery is at 25℃±2℃, use the battery test system to test the battery charge and discharge cycle.

[0055] Work step settings:

[0056] The first step: shelve it for 10 minutes;

[0057] Step 2: Charge with 0.3C constant current to the battery cut-off voltage of 3.65V, then switch to 3.65V constant voltage charging, with a cut-off current of 0.05C;

[0058] The third step: put it aside, time 10 minutes;

[0059] The fourth step: constant current discharge, the discharge current is 0.5C;

[0060] Step 5: Cycle, from the beginning of the firs...

Embodiment 2

[0075] Example 2: (1) Prepare a 25Ah lithium iron phosphate battery with a rated capacity of 25Ah and a nominal voltage of 3.2V. Place the battery in an environment of 20°C, 1 standard atmosphere, and 40% relative humidity, and keep it until the surface temperature of the battery At 20℃±2℃, use the battery test system to test the battery charge and discharge cycle.

[0076] Work step settings:

[0077] The first step: shelve it for 10 minutes;

[0078] Step 2: Charge with 0.5C constant current to the battery cut-off voltage of 3.65V, then switch to 3.65V constant voltage charging, with a cut-off current of 0.05C;

[0079] The third step: put it aside, time 10 minutes;

[0080] Step 4: Constant current discharge, the discharge current is 1C;

[0081] Step 5: Cycle, from the beginning of the first cycle to the end of the fourth cycle, the number of cycles is three;

[0082] The sixth step: shelve it for 10 minutes;

[0083] Step 7: Charge the battery at a constant current of 0.5C to a cut-o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com