Self heat dissipation type long-life processing machine tool

A processing machine tool and self-radiating technology, which is applied to metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems that affect the service life of the equipment and the heat cannot be dissipated quickly, and achieve the effect of prolonging the service life and avoiding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below, the technical solution of the present invention will be described in detail through specific examples.

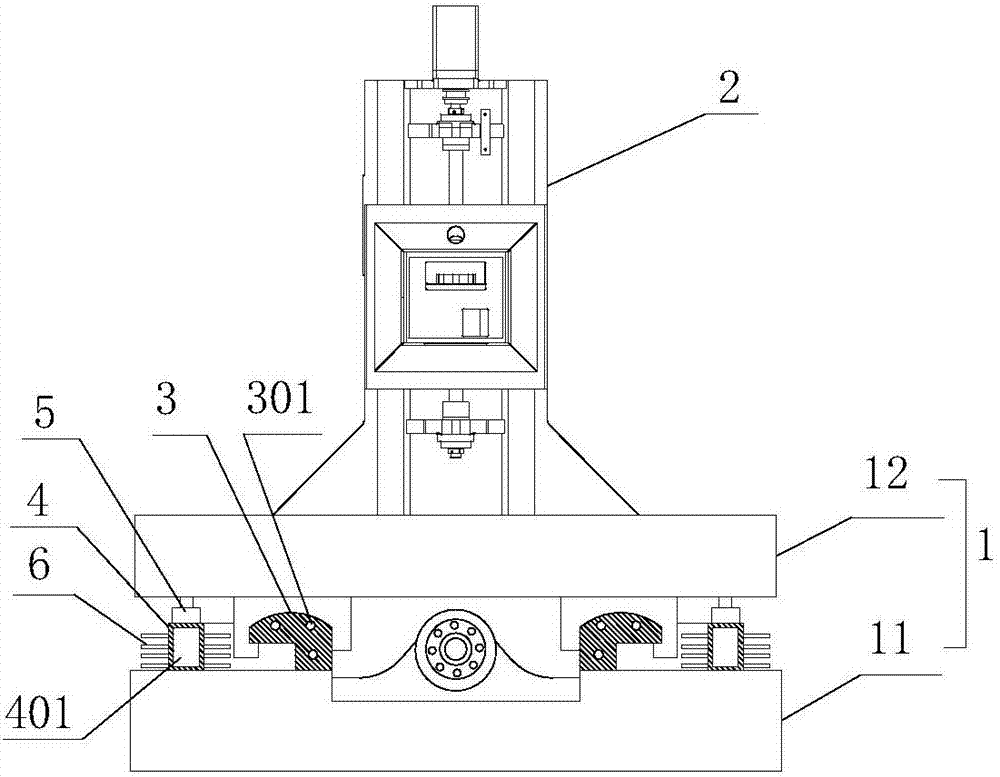

[0016] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a self-radiating high-life processing machine tool proposed by the present invention.

[0017] refer to figure 1 , a self-radiating high-life processing machine tool proposed by the embodiment of the present invention, comprising: a machine bed 1 and a column 2 located on one side of the machine bed 1, the machine tool bed 1 includes a base 11 and a worktable 12, the The base 11 is provided with a guide rail 3 integrally formed with it, the workbench 12 is located above the base 11 and is slidably mounted on the guide rail 3, and the side of the column 2 close to the machine bed 1 is provided with a column that can be moved up and down along the height direction of the column 2. A moving processing head in which:

[0018] On the base 11 and on one side of the guide rail 3, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com