Method for making molar rod

A molar stick and cowhide technology, applied in the field of pet toys, can solve the problems of pure cowhide with a single shape and color, poor dog grinding effect, and difficulty in arousing the dog's interest, etc., and achieves uniform appearance, good softening effect, and improved immunity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

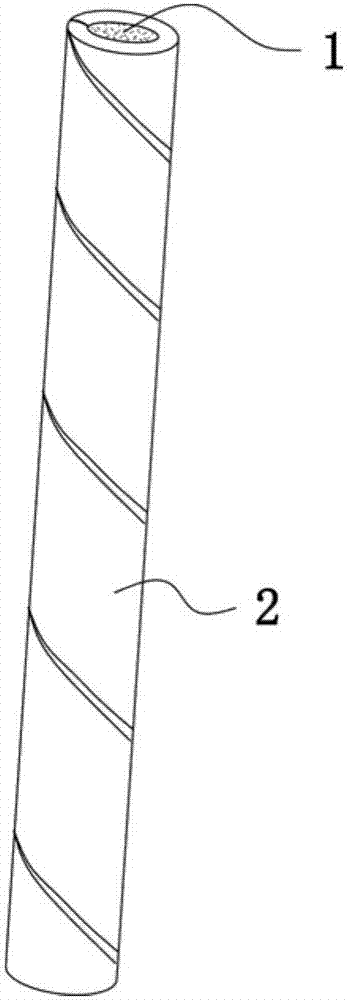

[0023] Such as figure 1 As shown, a method for manufacturing a molar stick includes an inner core 1 and a cowhide layer 2 arranged outside the inner core, and the cowhide layer 2 is spirally wound outside the inner core 1; The inner core includes the following components: 100 parts of corn modified starch, 5 parts of edible glycerin, 0.5 part of bone gum, 0.5 part of animal bone calcium powder, 1.5 parts of carrot, 0.3 part of hawthorn, 0.1 part of pet flavor powder, 1 part of dietary fiber , 0.1 part of whey protein, 0.3 part of blueberry juice, 0.01 part of food coloring and 0.01 part of food flavor; the taste of food flavor can be adjusted according to actual needs, such as mint, milk, strawberry, fennel, chicken, etc.; The specific manufacturing principle is the prior art, and will not be described in detail; modified starch is the prior art, and its characteristics and processing technology are all prior art. Corn modified starch is one of the types, and its characteristi...

Embodiment 2

[0031] Such as figure 1 As shown, a method for manufacturing a molar stick includes an inner core 1 and a cowhide layer 2 arranged outside the inner core, and the cowhide layer 2 is spirally wound outside the inner core 1; The inner core includes the following components: 50 parts of corn modified starch, 50 parts of potato modified starch, 10 parts of edible glycerin, 2 parts of bone gum, 1 part of animal bone calcium powder, 1 part of carrot, 0.5 part of hawthorn, 0.5 part of pet flavor powder 3 parts of dietary fiber, 0.5 part of whey protein, 0.4 part of blueberry juice, 0.05 part of food coloring and 0.05 part of food flavor; the taste of food flavor can be adjusted according to actual needs, such as mint, milk, strawberry, fennel flavor, chicken flavor, etc.; the specific manufacturing principle is the prior art, and will not be repeated; modified starch is the prior art, and its characteristics and processing technology are all existing technologies. The process is als...

Embodiment 3

[0039] Such as figure 1 As shown, a method for manufacturing a molar stick includes an inner core 1 and a cowhide layer 2 arranged outside the inner core, and the cowhide layer 2 is spirally wound outside the inner core 1; The inner core includes the following components: 100 parts of tapioca modified starch, 8 parts of edible glycerin, 1 part of bone gum, 0.8 part of animal bone calcium powder, 1.5 parts of carrot, 0.5 part of hawthorn, 0.3 part of pet flavor powder, 2 parts of dietary fiber , 0.3 parts of whey protein, 0.2 parts of blueberry juice

[0040] , 0.03 parts of food coloring and 0.03 parts of food flavoring; the taste of food flavoring can be adjusted according to actual needs, such as mint flavor, milk flavor, strawberry flavor, fennel flavor, chicken flavor, etc.; the specific manufacturing principle is the existing technology, no longer repeat Modified starch is prior art, and its characteristic, processing technology are prior art, and cassava modified starch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com