Waste gas treatment device with anticorrosion function

A kind of exhaust gas treatment equipment and exhaust gas treatment technology, which is applied in the direction of cleaning methods and appliances, cleaning hollow objects, fixed filter element filters, etc., can solve the problems of inconvenient filter replacement, corrosion of garbage disposal boxes, etc., and achieve convenient disassembly and prevent Corrosion, easy to install and fix the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

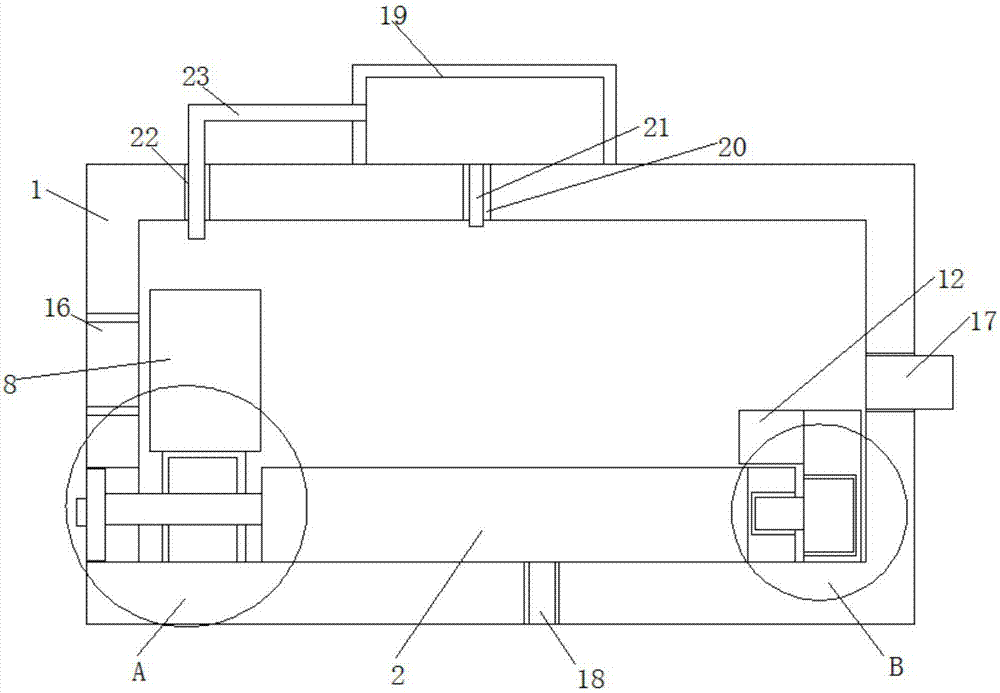

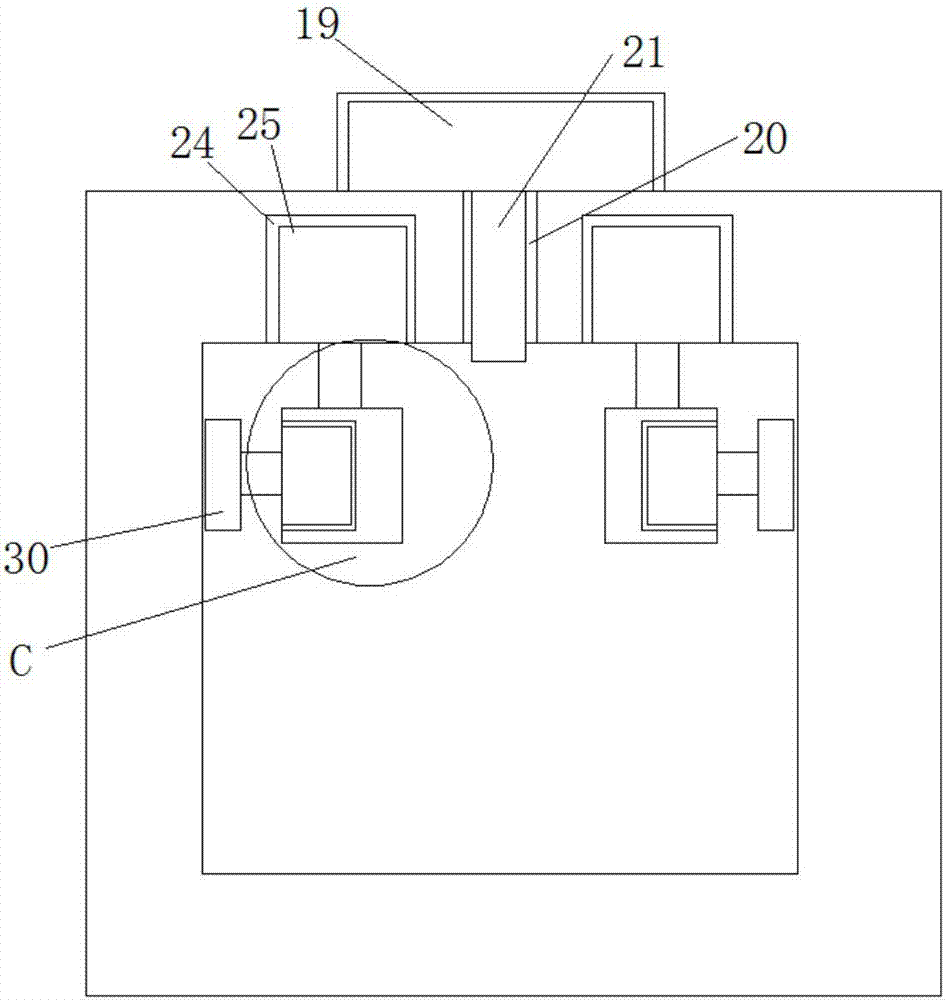

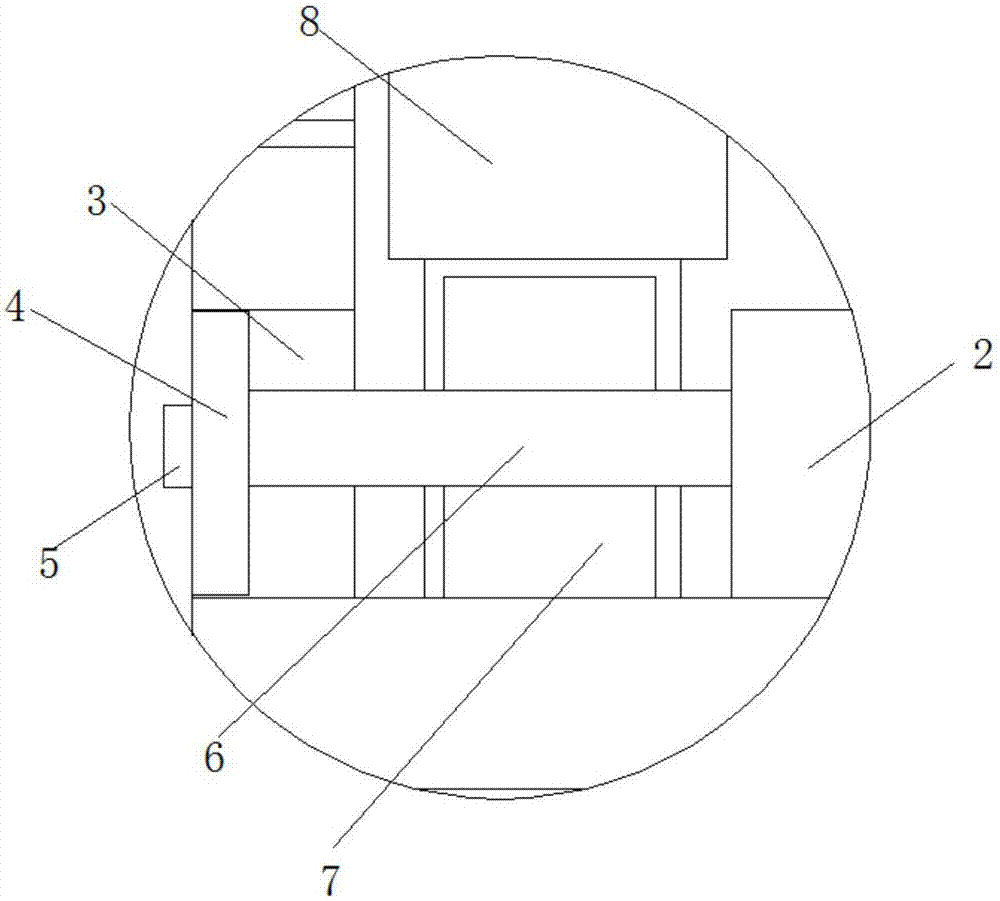

[0024] refer to Figure 1-5 , a kind of waste gas treatment equipment with anti-corrosion function, comprising a waste gas treatment box 1, a filter screen 2 is slidably installed on the bottom inner wall of the waste gas treatment box 1, and a through hole 3 is opened at the bottom of one side of the waste gas treatment box 1, and the through hole A baffle 4 is slidingly installed inside the 3, and a handle 5 is welded on the side of the baffle 4 away from the filter screen 2, and a moving column 6 is welded on the side of the filter screen 2 close to the handle 5, and the bottom inner wall of the exhaust gas treatment box 1 is welded There is a support pipe 7, the top of the support pipe 7 is fixedly equipped with a range hood 8, and the end of the moving column 6 close to the handle 5 extends into the through hole 3 and is welded with the baffle plate 4, and the side of the filter screen 2 away from the handle 5 is set There is an installation and fixing mechanism, and the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap