SCR (selective catalytic reduction) flue gas denitration reactor

A denitrification reactor and reactor technology, applied in the field of flue gas denitrification, can solve problems such as unbalanced thermal expansion of the reactor, and achieve the effects of coping with high temperature of flue gas, solving unbalanced thermal expansion, and reducing abrasion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings.

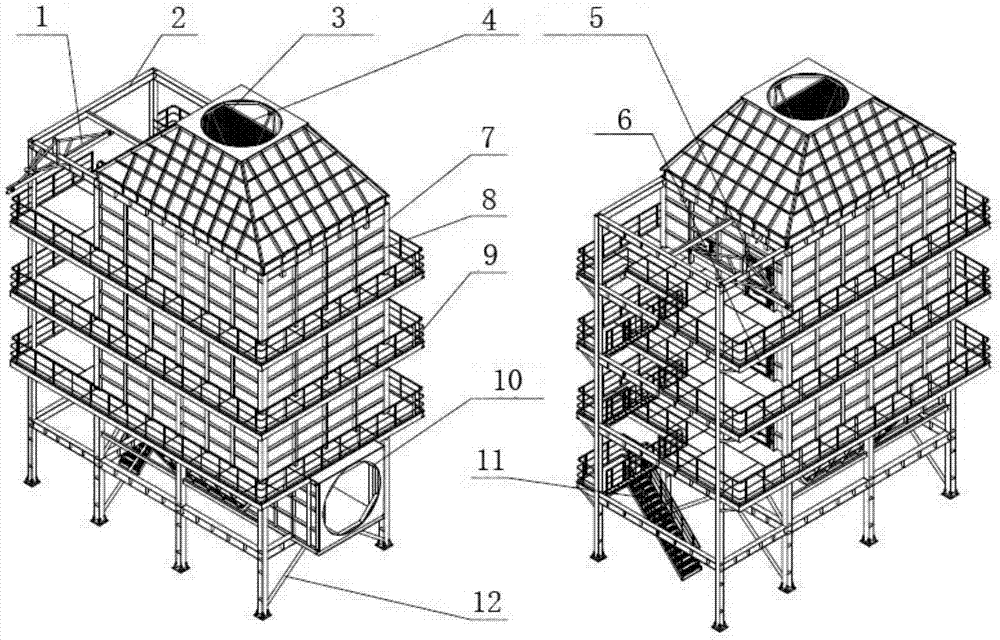

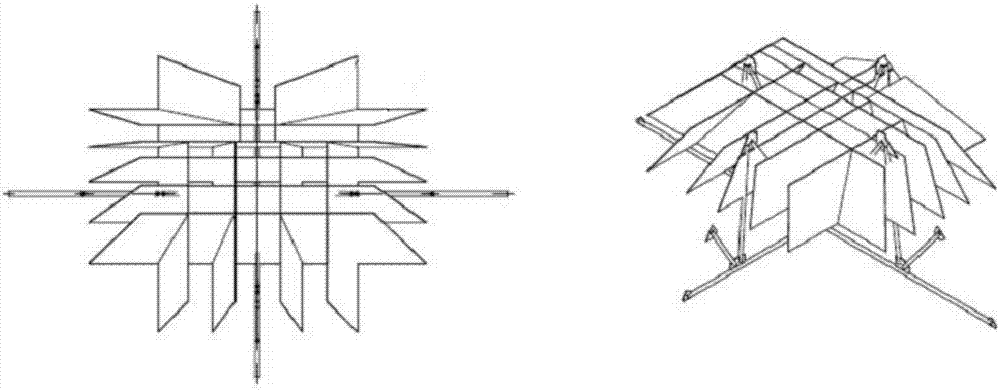

[0022] Exemplary SCR flue gas denitrification reactor of the present invention such as figure 1 As shown, it is vertical, filled with catalyst inside, including crane beam 1, beam 2, rectification grid 3, deflector plate 4 (15-40 pieces), catalyst transfer door 5, manhole door 6, column 7 (material It is alloy steel Q345B), wall plate 8, platform 9, flue assembly 10, inclined ladder 11, diagonal brace 12.

[0023] Columns 7 arranged in the vertical direction, beams 2 arranged in the horizontal direction, diagonal braces 11 connected between the columns 7 at the bottom for reinforcement, and wall panels 8 laid flat between the columns 7 and the beams 2 (for SCR method flue gas denitrification The reactor is sealed to isolate the external environment) to form the outer wall of the reactor, which is used to fix and protect the denit...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap