Method and device for making mobile phone card tray through MIM technology

A mobile phone card holder and process technology, which is applied in the direction of mechanical equipment, other manufacturing equipment/tools, turbines, etc., can solve the problems of uneven pressure in the cavity and affect the density consistency of different parts of the product, so as to improve the smoothness of the flow channel, Avoid uneven product density and promote fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

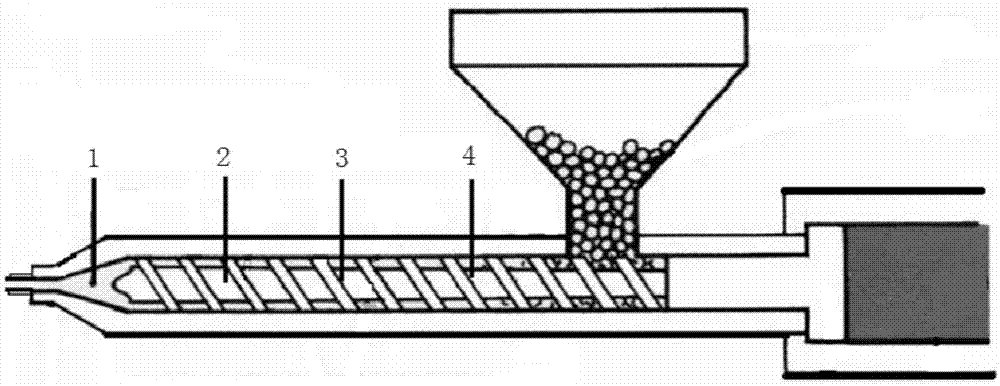

Image

Examples

example

[0037] 1. Select the Arburg 370S injection molding machine, install the Cato mold with chrome-plated runner on the mold base of the injection machine, and use the chrome-plated runner with the same diameter as the nozzle of the injection machine according to the diameter of the runner of the mold. Heat up the temperature (setting temperature 120°C).

[0038] 2. Turn on the heater of the barrel of the injection machine to heat in different zones. The temperature is set to 185°C in the first zone, 175°C in the second zone, 165°C in the third zone, and 155°C in the fourth zone.

[0039]The screw charging speed is 50r / min, the charging position is 50mm, the screw retreats to release the pressure by 2mm, and the screw rotates and retreats to the charging and metering completion position of 50mm (take the metering room in front of the front end check ring in the barrel as the origin, which is 0mm, 50r / Min rotate clockwise and add 50mm length of material to the metering chamber befo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com