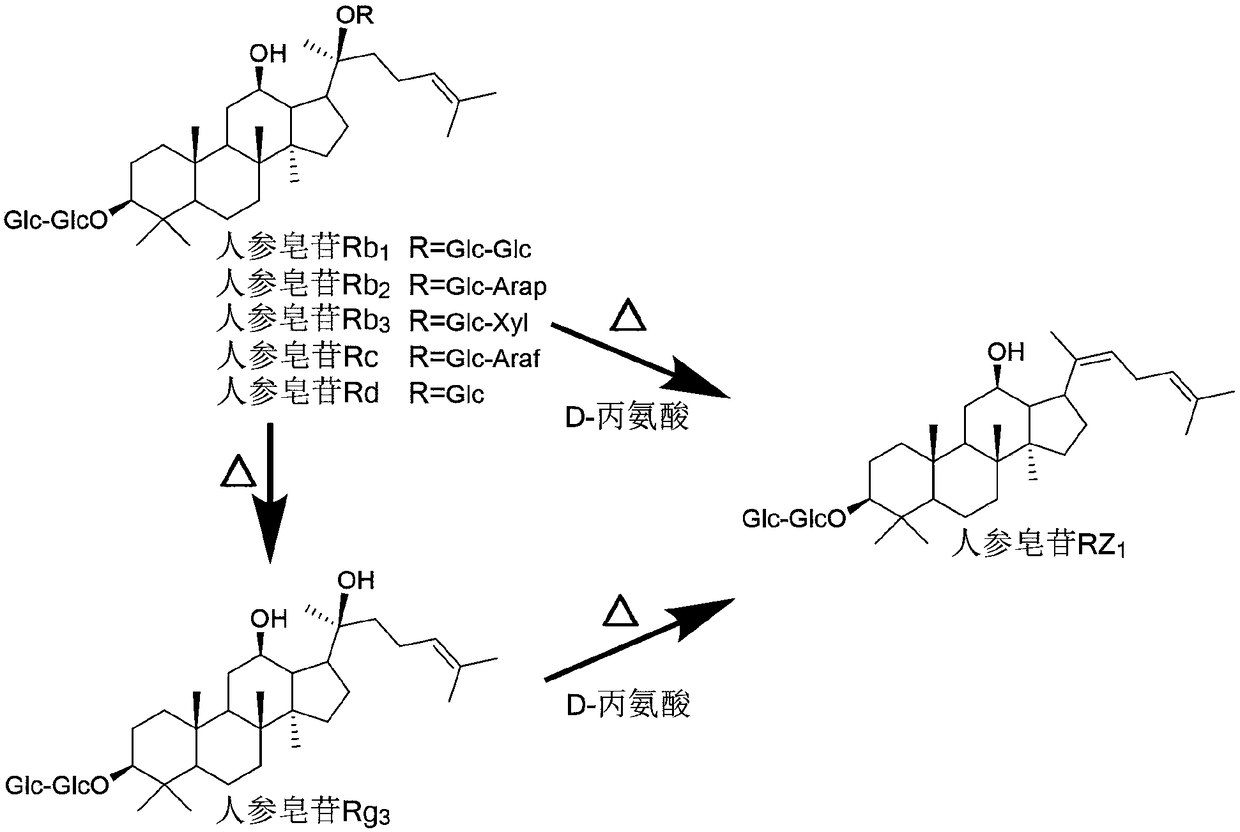

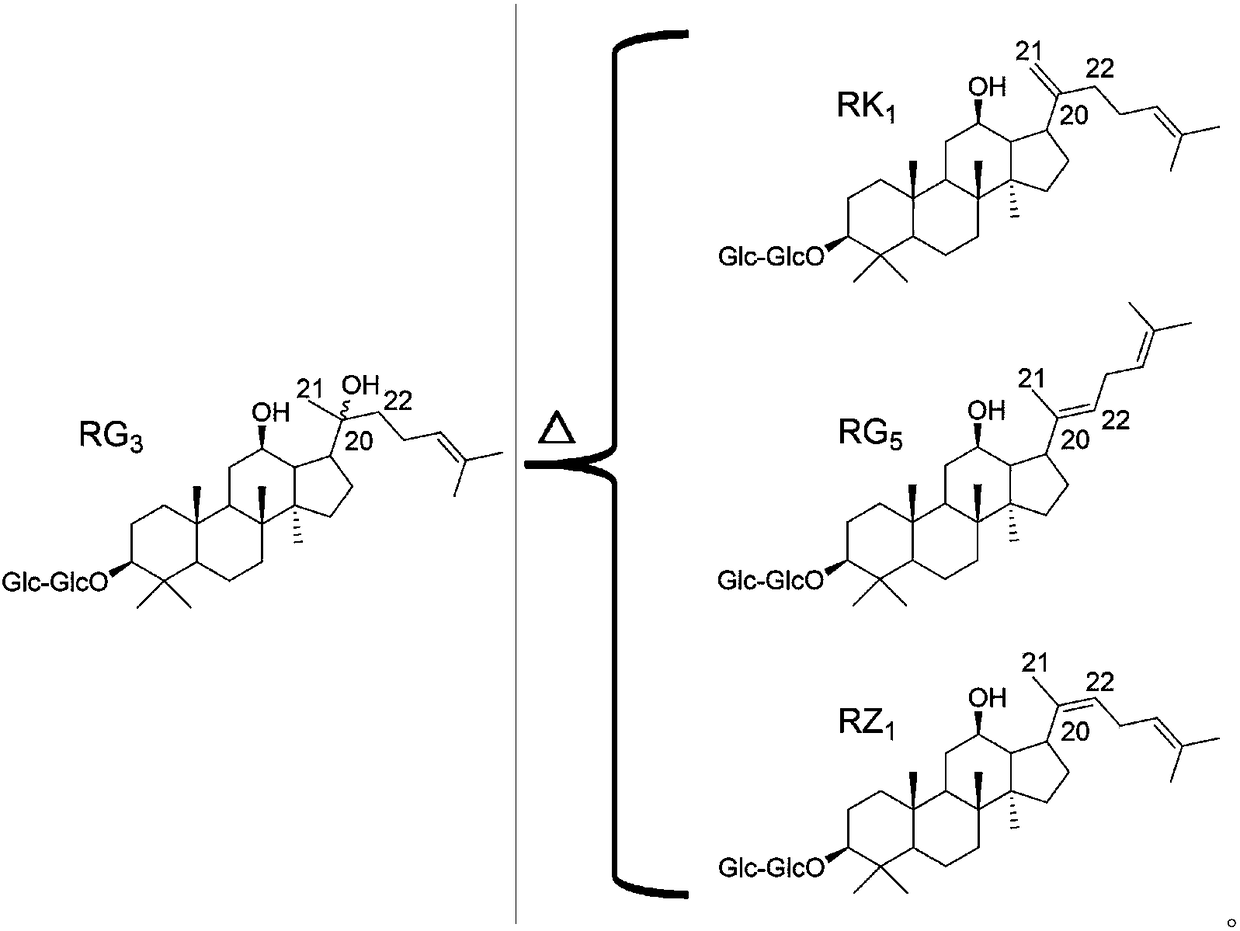

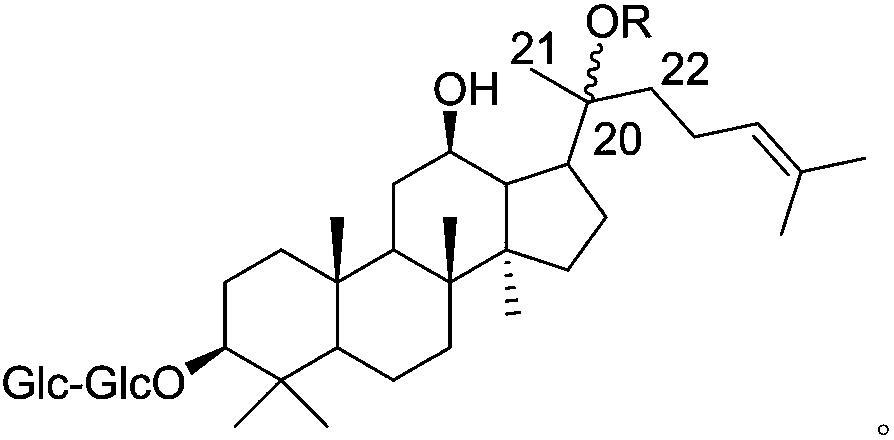

A method for preparing ginsenoside rz1 based on biogenic degradation pathway

A technology of ginsenoside and RZ1, which is applied in the field of preparation of ginsenoside RZ1 based on biogenic degradation pathways, can solve the problems of limiting the research on the pharmacological effects of ginsenoside RZ, low content, and difficult separation of standard products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: Ginsenoside Rb 1 Preparation of Ginsenoside RZ by Thermal Degradation 1

[0027] 1. Preparation of raw material solution

[0028] Ginsenoside Rb 1 Standard product (Shaanxi Huikangyuan Biomedical Technology Co., Ltd., purity > 98%) and D-alanine (Bailingwei Technology Co., Ltd., purity 99%) are dissolved in 30% ethanol aqueous solution to make ginsenoside Rb 1 The mass concentration is the solution of 5mg / mL, and the molar concentration of D-alanine is Rb 1 25% of the molar concentration.

[0029] 2. Thermal degradation method

[0030] The obtained raw material solution was transferred to a 100mL polytetrafluoroethylene-lined stainless steel reactor, and placed in a constant temperature oven for hydrothermal reaction at a reaction temperature of 170°C and a reaction time of 5 hours. After the reaction was completed, the reactor was taken out and cooled to room temperature.

[0031] Determination of Ginsenoside RZ in Thermal Degradation Products ...

Embodiment 2

[0039] Embodiment 2: Ginsenoside Rb 2 Preparation of Ginsenoside RZ by Thermal Degradation 1

[0040] 1. Preparation of raw material solution

[0041] Ginsenoside Rb 2 Standard substance (Shanghai Rongbai Biotechnology Co., Ltd., purity > 98%) and D-alanine (Bailingwei Technology Co., Ltd., purity 99%) are prepared by dissolving ginsenoside Rb with a volume percentage concentration of 30% ethanol solution 2 The mass concentration is the solution of 5mg / mL, and the molar concentration of D-alanine is Rb 2 25% of the molar concentration.

[0042] 2. Thermal degradation method

[0043] The obtained raw material solution was transferred to a 100mL polytetrafluoroethylene-lined stainless steel reactor, and placed in a constant temperature oven for hydrothermal reaction at a reaction temperature of 170°C and a reaction time of 5 hours. After the reaction was completed, the reactor was taken out and cooled to room temperature.

[0044] Determination of Ginsenoside RZ in The...

Embodiment 3

[0051] Embodiment 3: Ginsenoside Rb 3 Preparation of Ginsenoside RZ by Thermal Degradation 1

[0052] 1. Preparation of raw material solution

[0053] Ginsenoside Rb 3 Standard substance (Shanghai Valan Biotechnology Co., Ltd., purity > 98%) and D-alanine (Bailingwei Technology Co., Ltd., purity 99%) are prepared by dissolving ginsenoside Rb with a volume percentage concentration of 30% ethanol solution 3 The mass concentration is the solution of 5mg / mL, and the molar concentration of D-alanine is Rb 3 25% of the molar concentration.

[0054] 2. Thermal degradation method

[0055] The obtained raw material solution was transferred to a 100mL polytetrafluoroethylene-lined stainless steel reactor, and placed in a constant temperature oven for hydrothermal reaction at a reaction temperature of 170°C and a reaction time of 5 hours. After the reaction was completed, the reactor was taken out and cooled to room temperature.

[0056] Determination of Ginsenoside RZ in Therm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com