Formula of regulating seat material and processing method thereof

A technology of adjusting seat and formula, which is applied in the field of equipment materials, can solve the problems of low tensile strength, fast corrosion rate, low heat distortion temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

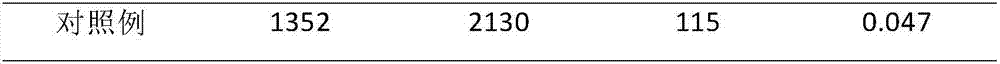

Examples

Embodiment Construction

[0012] In the first embodiment of the present invention, the adjustment seat of the present invention is manufactured according to the above steps, and in parts by weight:

[0013] Step 1: Add 1650 parts of ultrapure water with a conductivity of 3.43us / cm into the reactor, start the stirrer in the reactor at a speed of 92rpm, start the heating pump to raise the temperature in the reactor to 95°C, and then add 2,2'-(3,3'-Dioxy-1,1'-biphenyl-4,4'-bisazo)bis[N-(2-methoxyphenyl)-3-oxo- Butanamide] 153 parts, cyano-(3-phenoxyphenyl) methyl-3-(2,2-dioxyethenyl)-2,2-dimethylcyclopropane carboxylate 135 parts, 3 -85 parts of phenoxyphenyl-2,2-dimethyl-3-(2,2-dichlorovinyl)-1-cyclopropanecarboxylate, stir until completely dissolved, adjust the pH value to 3.36, and The rotation speed of the stirrer was adjusted to 189rmp, the temperature was 151°C, and the esterification reaction was carried out for 15 hours.

[0014] The second step: take 136 parts of (3-phenylchlorophenyl)methyl-3-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com