Oil-based ink for engineering blueprint printing and preparation method thereof

An engineering blueprint and oil-based technology, which is applied to inks, applications, household appliances, etc., can solve the problems that cannot meet the wide-format printing requirements of engineering blueprints, difficult to recycle, waste of resources, and other problems, so as to prolong the preservation time of archives and the use of materials Environmental protection, high printing definition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

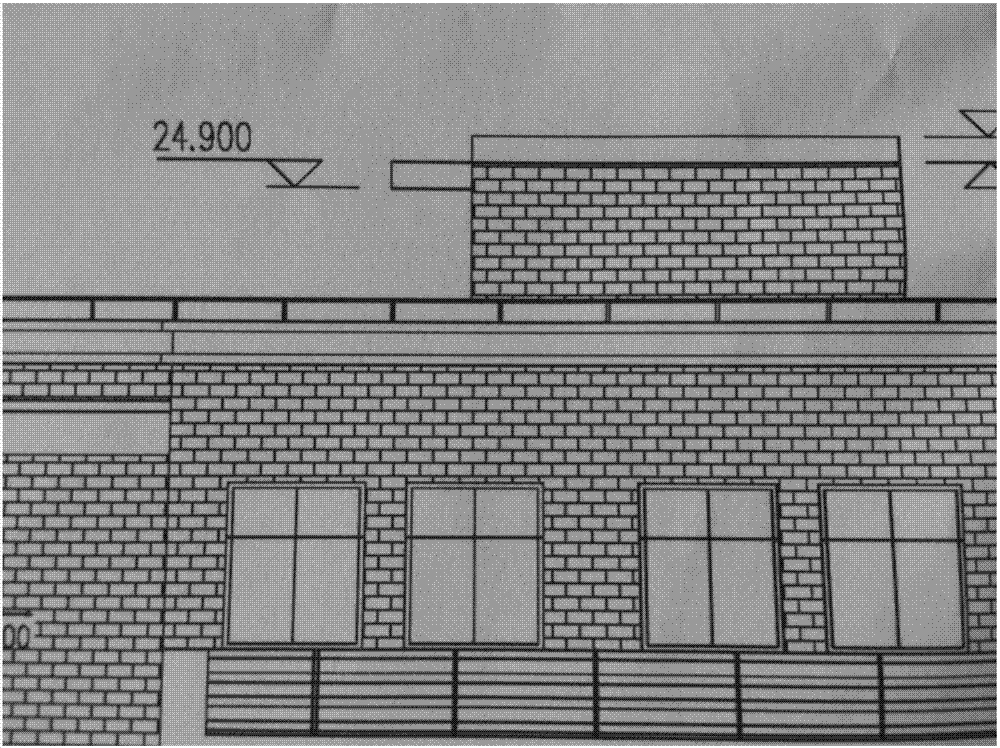

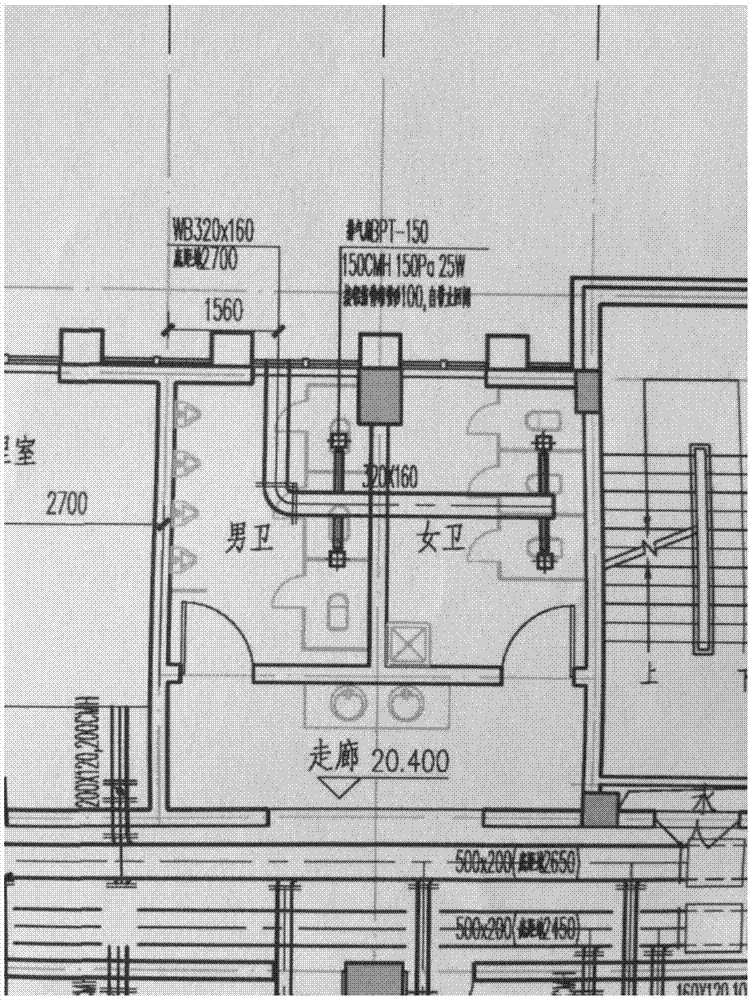

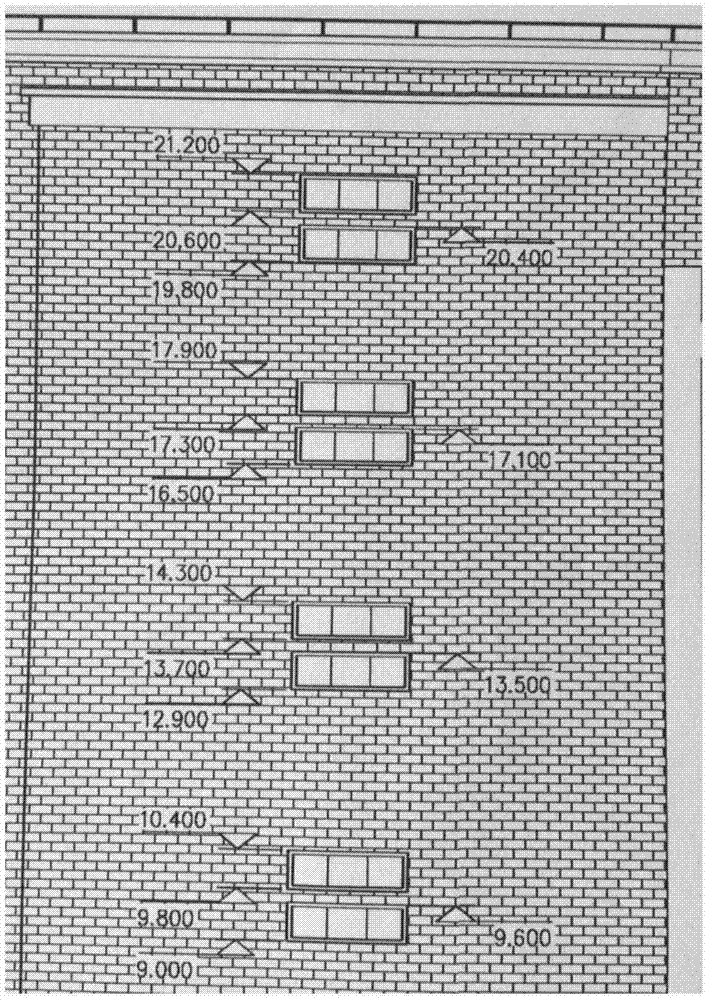

Image

Examples

preparation example Construction

[0032] The preparation method of oil-based ink of the present invention comprises the following steps:

[0033] 1) Put the above components except the pigment into the dispersion tank in turn, and stir for 20 minutes at 200-500r / min until the material is uniform;

[0034] 2) Slowly add the pigment under the stirring state of 200r / min. After the mixing is completed, adjust the rotation speed to 800-1200r / min and disperse for 30-60min until the mixture is uniform;

[0035] 3) Send the dispersed mixed solution to a sand mill to grind until the particle size D50 is less than 150nm, and send the ground mixed solution to a centrifuge for centrifugation to remove impurities. The specific parameters of the centrifuge are set as: flow rate 20-50L / h , the rotation speed is 5000~20000r / min, and then filtered with 0.5μm filter paper, that is.

Embodiment 1

[0037] An oil-based ink for engineering blueprint printing, which includes the following components by mass percentage:

[0038]

[0039] The preparation method of this oil-based ink is as follows:

[0040] Put the above components except the pigment Paliogen L6360 into the dispersion tank in turn, adjust the speed to 500r / min, stir for 20min until the material is uniform; slowly add the pigment PaliogenL6360 under the stirring state of 200r / min, adjust the speed after the mixing is completed Disperse at 1200r / min for 45 minutes until evenly mixed; transport the dispersed mixed solution to a sand mill for grinding until the particle size D50 is less than 150nm, and transport the ground mixed solution to a centrifuge for centrifugation to remove impurities. The specific parameters of the centrifuge are set It is: the flow rate is 35L / h, the rotation speed is 12000r / min, and then filtered with 0.5μm filter paper.

Embodiment 2

[0042] An oil-based ink for engineering blueprint printing, which includes the following components by mass percentage:

[0043]

[0044] The preparation method of this oil-based ink is as follows:

[0045] Put the above components except the pigment Paliogen L6360 into the dispersion tank in turn, adjust the speed to 200r / min, stir for 20min until the material is uniform; slowly add the pigment PaliogenL6360 under the stirring state of 200r / min, adjust the speed after the mixing is completed Disperse at 800r / min for 30min until evenly mixed; transport the dispersed mixed solution to a sand mill for grinding until the particle size D50 is less than 150nm, and transport the ground mixed solution to a centrifuge for centrifugation to remove impurities. The specific parameters of the centrifuge are set It is: the flow rate is 40L / h, the speed is 15000r / min, and then filtered with 0.5μm filter paper.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com