Production process method for converter steelmaking

A converter steelmaking and production process technology, applied in the manufacture of converters, etc., can solve problems such as carbon-oxygen reaction instability, splashing, and back-drying, and achieve the goals of improving steelmaking efficiency, preventing splashing, and saving production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

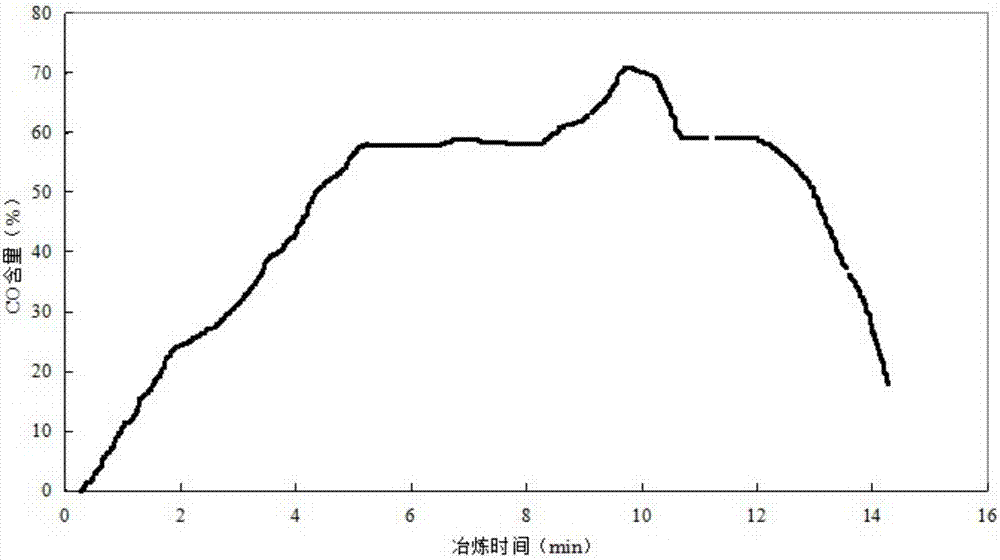

[0012] A production process method for converter steelmaking, comprising a dynamic converter steelmaking system and a data communication system, wherein: a gas analyzer is also included, and the gas analyzer is connected to the converter flue in the dynamic converter steelmaking system through pipelines It is used to collect the flue gas in the converter flue and analyze the content of carbon monoxide in the flue gas, and transmit it to the furnace front operation platform of the dynamic converter steelmaking system through the data communication system, and then use the dynamic converter steelmaking system to draw the trend of CO in the furnace in real time According to the graph, the material in the converter steelmaking is adjusted according to the trend chart of CO according to the conventional method. A converter smelting cycle is divided into three stages. The normal trend chart of CO is a smooth curve. Except for a part of the CO-containing gas generated during the blowi...

Embodiment 2

[0014] Slag overflow in the early stage of converter smelting:

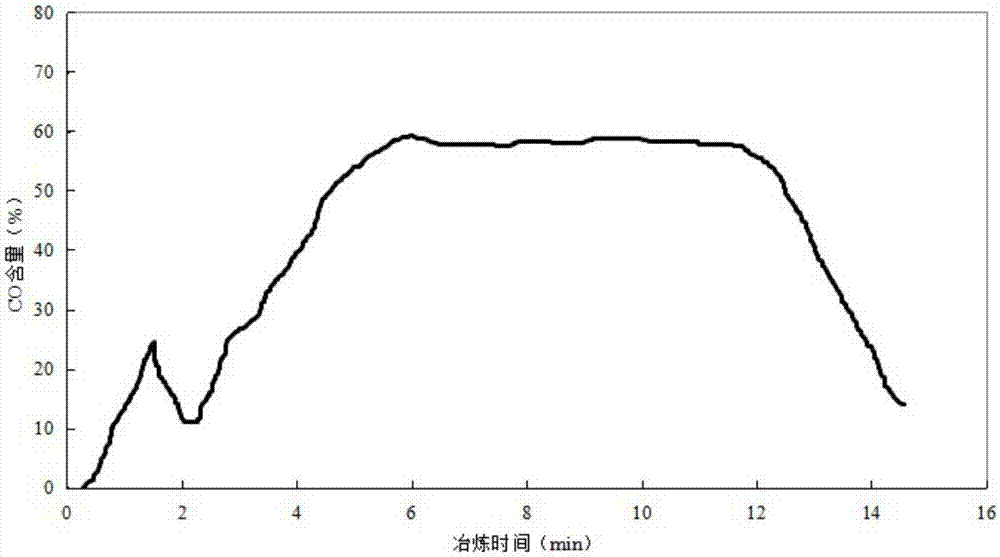

[0015] In the actual production process, at the initial stage of smelting, as elements such as Si, Mn, P, and Fe in molten iron begin to oxidize, C is also oxidized synchronously, and as the temperature continues to increase, the CO content also increases. 3min, the first batch of slag added and the oxidized elements also began to react continuously to form the first batch of slag. The shape and composition of the system are also reflected in the CO curve, that is, the CO value begins to decrease after reaching a small peak, see figure 1 . This phenomenon is due to the change of the slag slag system, and more gas is trapped in the slag, which makes it unable to be discharged out of the furnace in time. As more and more gas is hindered from being discharged, the foamy slag formed gradually increases until it overflows, and the slag foam appears. In the early stage of smelting, it is necessary to add slag materia...

Embodiment 3

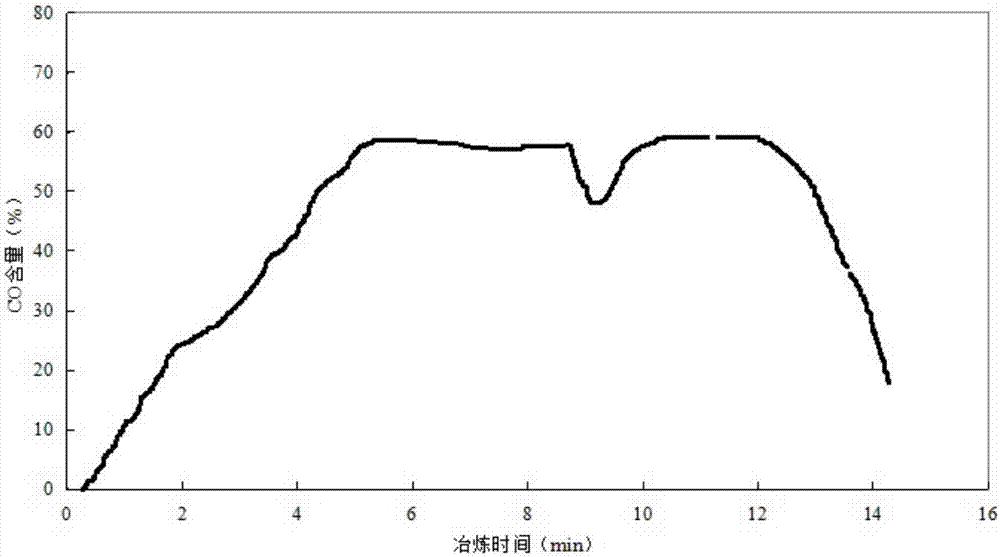

[0017] Mid splatter:

[0018] The change of CO in the furnace gas when the slag is splashed is shown in image 3 . In the middle stage of smelting, if the trend chart of CO shows a significant drop, it means that splashing will occur. The middle stage of smelting is the intense reaction period of C and O. Normally, the CO content will be stable at a high value area in the middle stage of smelting. If the slag is foamed at this stage , it will cause a large amount of gas to stagnate in the slag, the gas content in the CO trend chart will drop obviously, the slag will also expand rapidly, and splashing will occur in a short time. If this phenomenon occurs, it is necessary to add slag first to break the foamy slag At the same time, the position of the gun can be changed. The position of the gun can be interchanged between high and low, and the slag system can also be adjusted to a low position.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com