Automobile hub thermal treatment conveying device

A technology for automobile hubs and transmission devices, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of high furnace temperature, poor working environment, and high manufacturing costs, and achieve high work efficiency, fast expansion and contraction speed, and improved processing quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the present invention is not limited.

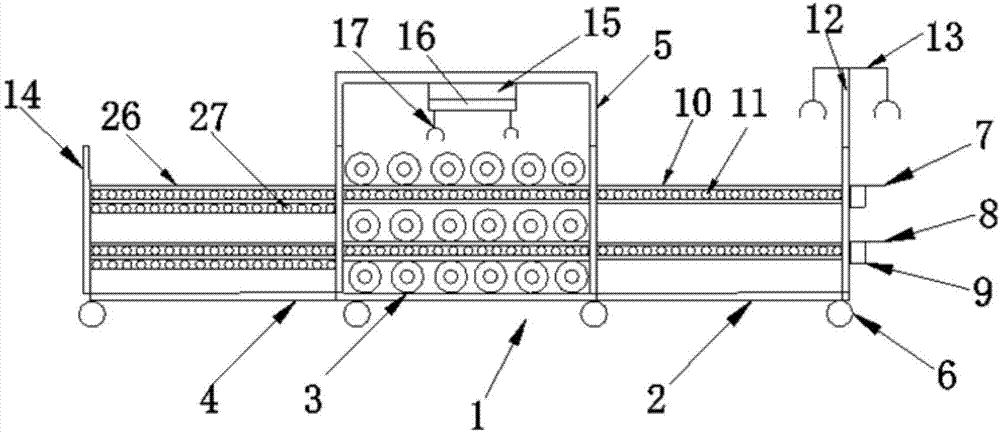

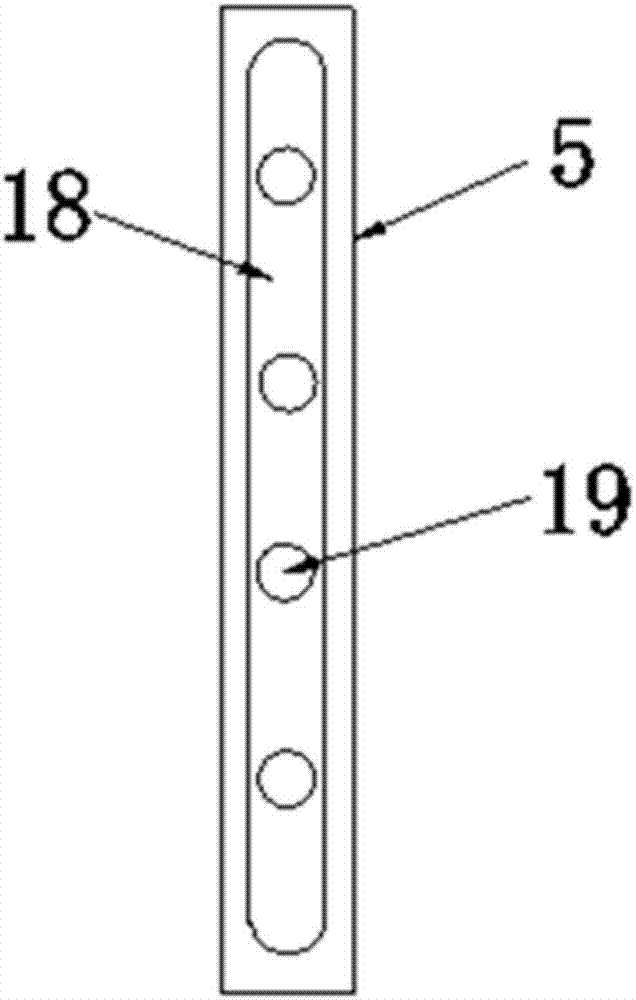

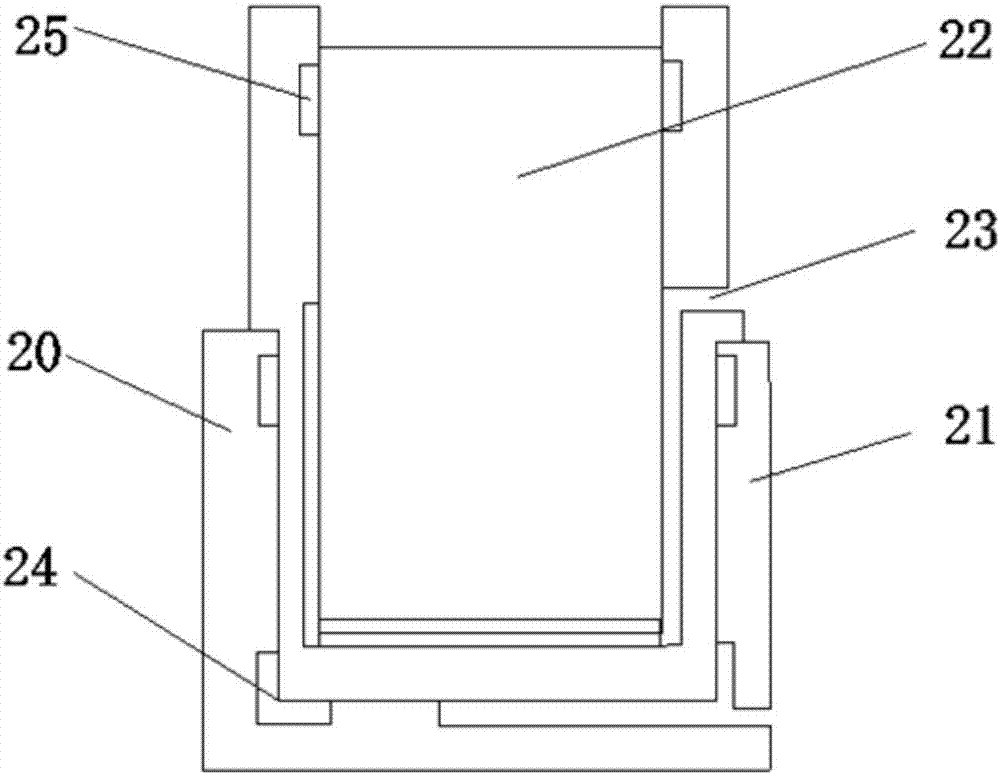

[0028] The automobile hub heat treatment transmission device provided by the invention has a structure such as Figure 1 to Figure 3 As shown, it includes a body 1, a feeding frame 2, a heating frame 3 and a discharging frame 4, wherein: the body 1 is provided with a heating frame 3, and an adjustable clamping bracket 5 is provided above the heating frame 3, The left side of described heating frame 3 is fixedly installed discharging frame 4, and the right side of described heating frame 3 is fixedly installed feeding frame 2, and the bottom of described feeding frame 2, heating frame 3, discharging frame 4 is all provided with rolling guide. round 6.

[0029] The main body 1 is a basic frame of the device, and is used to install other components such as the feeding frame 2, the heating frame 3, and the discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com