ic lead frame chip electroplating silver plating machine

A lead frame and chip type technology, which is applied in the field of IC lead frame chip electroplating silver plating machine, can solve the problems of low production efficiency of the electroplating machine, achieve convenient and quick adjustment, improve efficiency, and prevent the effect of clogging the nozzle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

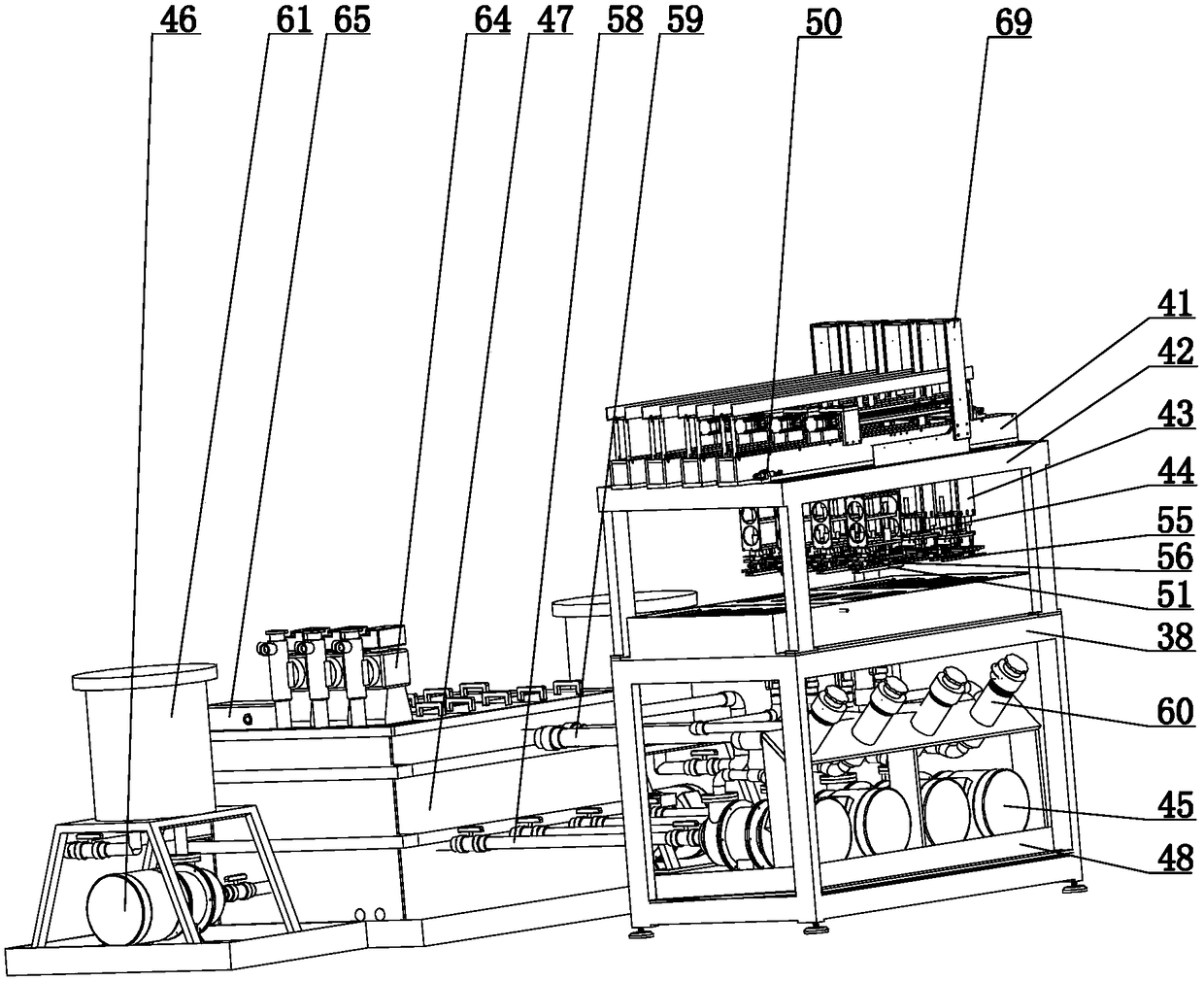

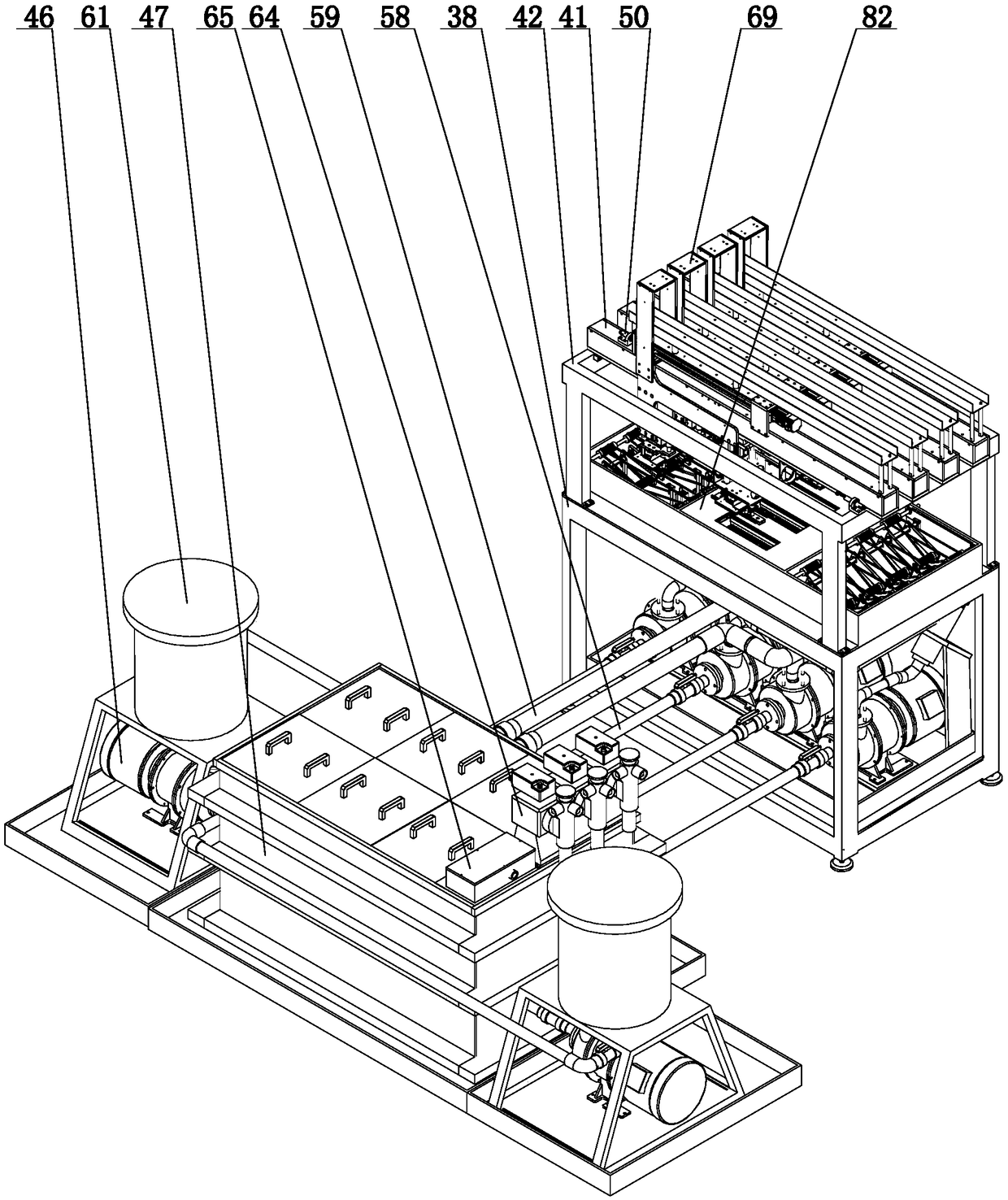

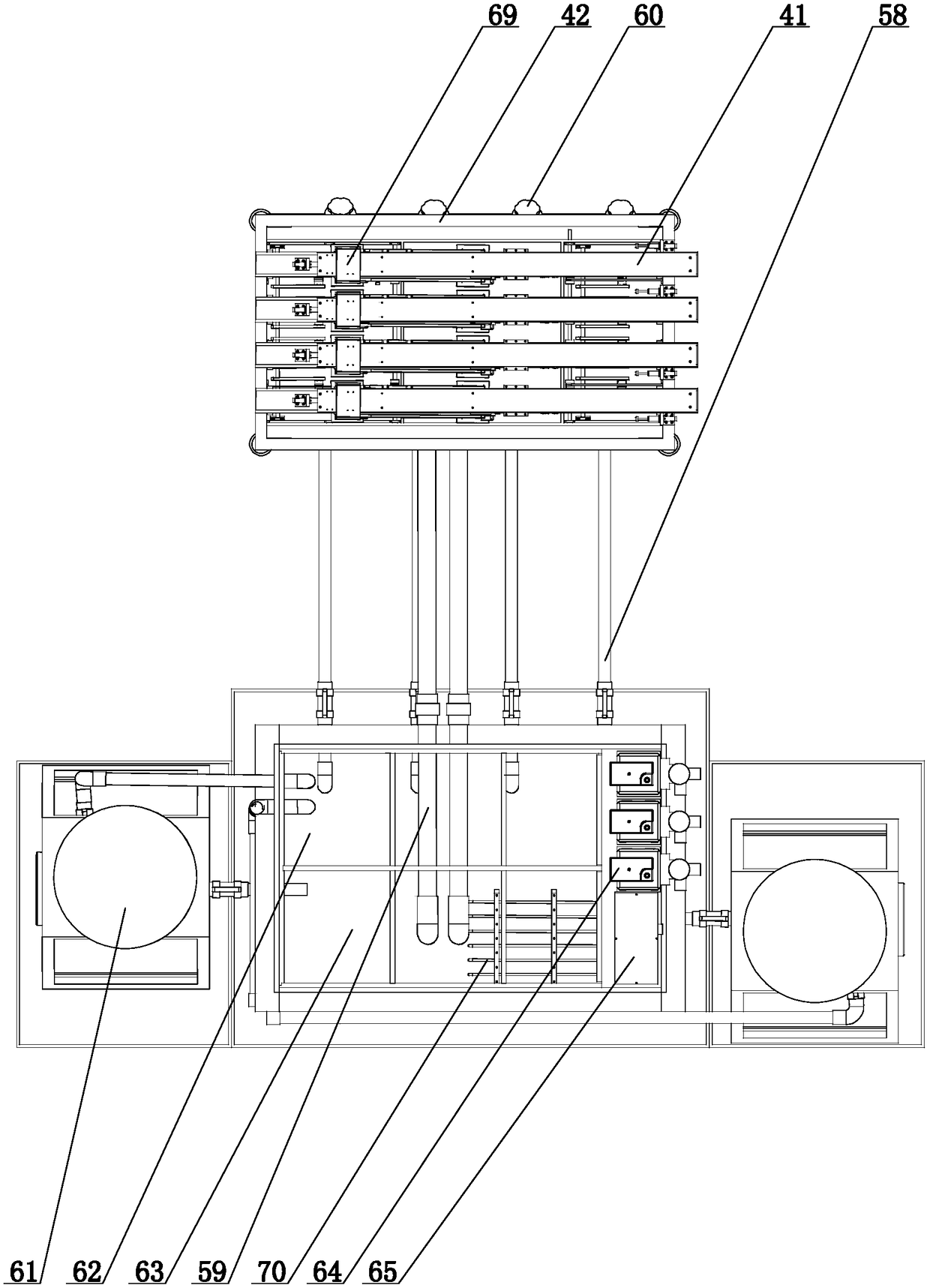

[0028] Such as Figure 1~10 The shown IC lead frame chip electroplating and silver plating machine includes a bottom platform D38, and the middle surface of the bottom platform D38 is provided with a drug discharge cylinder 39, which is a square shape, and the area of the drug discharge cylinder 39 is relatively large, and the chemical discharge cylinder 39 has a large area per unit time. It can hold more potion and discharge it into the silver water tank. It can open all channels for production at any time, and the production efficiency is greatly improved. Moreover, there is a large space between the template grooves 40, which is very convenient when replacing the template. The medicine discharge cylinder cover 82, the height of the upper surface of the medicine discharge cylinder cover 82 is higher than the height of the upper surface of the template groove 40, preventing the liquid medicine that is full after the silver plating reaction from splashing out of the medicine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com