3D-printed double-layer composite exterior wall board

A composite exterior wall panel, 3D printing technology, applied in building materials, building components, buildings, etc., can solve the problems of insufficient use of steel structure advantages in construction speed, poor fire prevention, waterproof, thermal insulation, sound insulation and other problems, and achieve convenient Standardized construction and installation, rich textures and colors, and fast installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

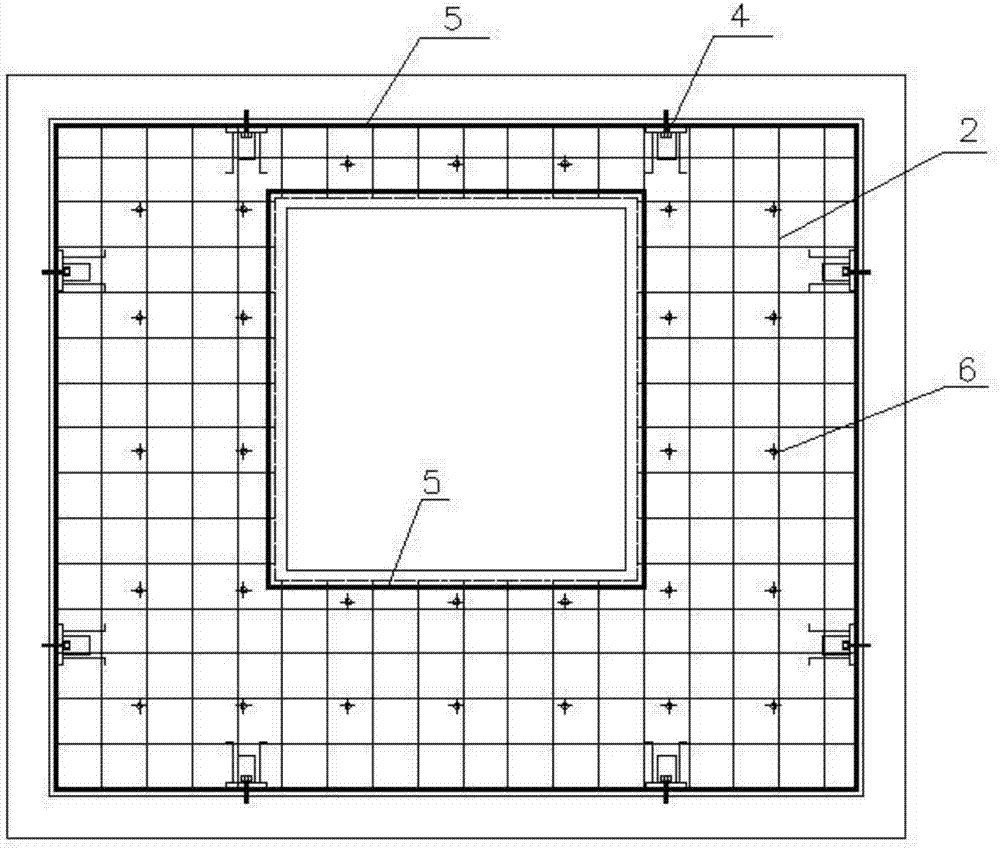

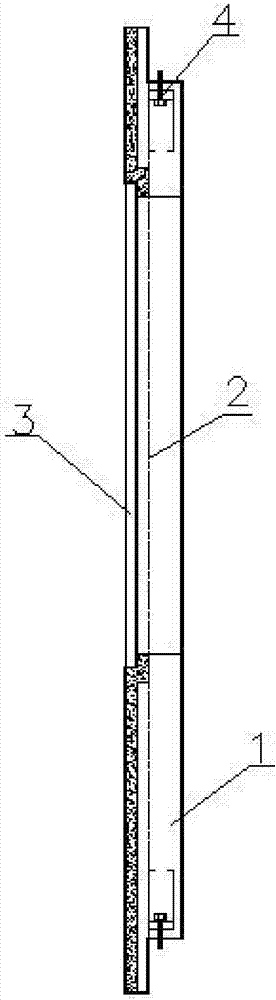

[0028] see figure 1 and figure 2 , the present invention provides a technical solution: a 3D printed double-layer composite exterior wall panel, including a composite exterior wall panel core layer and an outer protective layer decoration layer, the composite exterior wall panel core layer includes a foam concrete thermal insulation, fireproof and sound insulation wall Layer (1), steel wire mesh reinforcement layer (2), wall embedded parts (4) and steel wire mesh peripheral reinforcement steel bars (5), the outer protective layer decoration layer includes high-density fiber concrete waterproof surface layer (3); The core layer of the composite exterior wall panel is connected with the decorative layer of the outer protection layer through a fiber connector (6);

[0029] The foam concrete thermal insulation, fireproof and soundproof wall layer (1) is formed by adding admixtures with waste materials such as tailings, mixing and stirring, and 3D printing;

[0030] The steel wi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap