Laying method of prestressed steel cable in steel pipe body

A technology of prestressed steel cables and steel pipes, applied in the processing of building materials, construction, building construction, etc., can solve problems such as damage, low construction efficiency, and increased difficulty in quality control, achieve excellent bearing capacity characteristics, and save materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

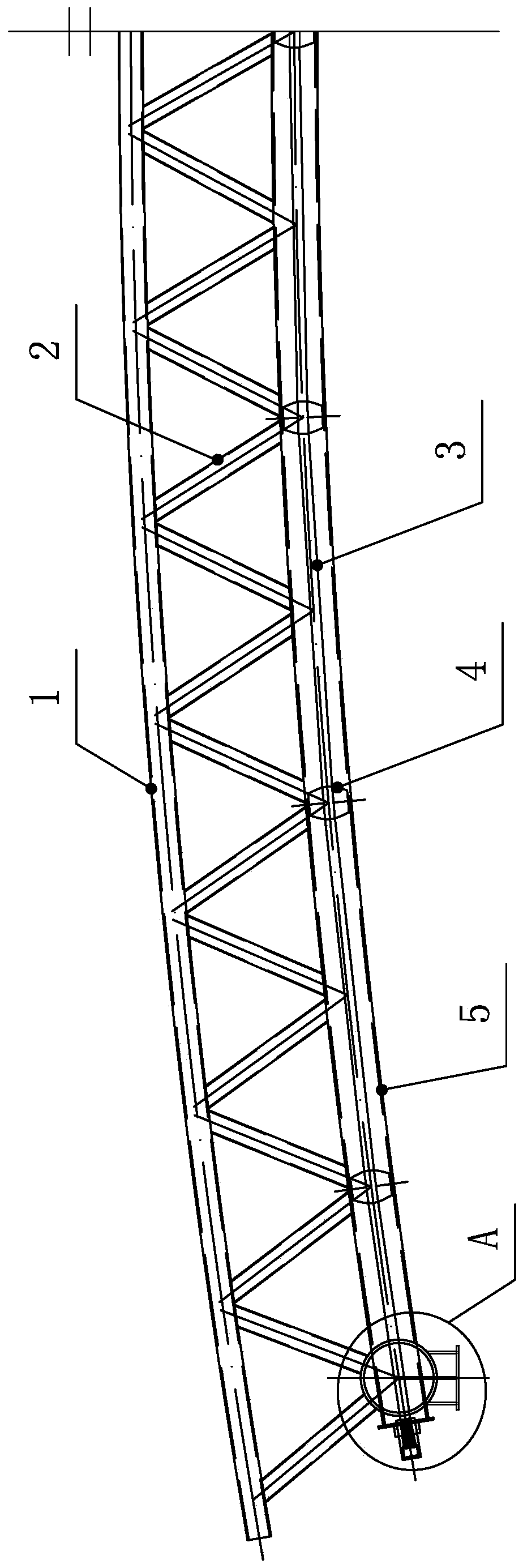

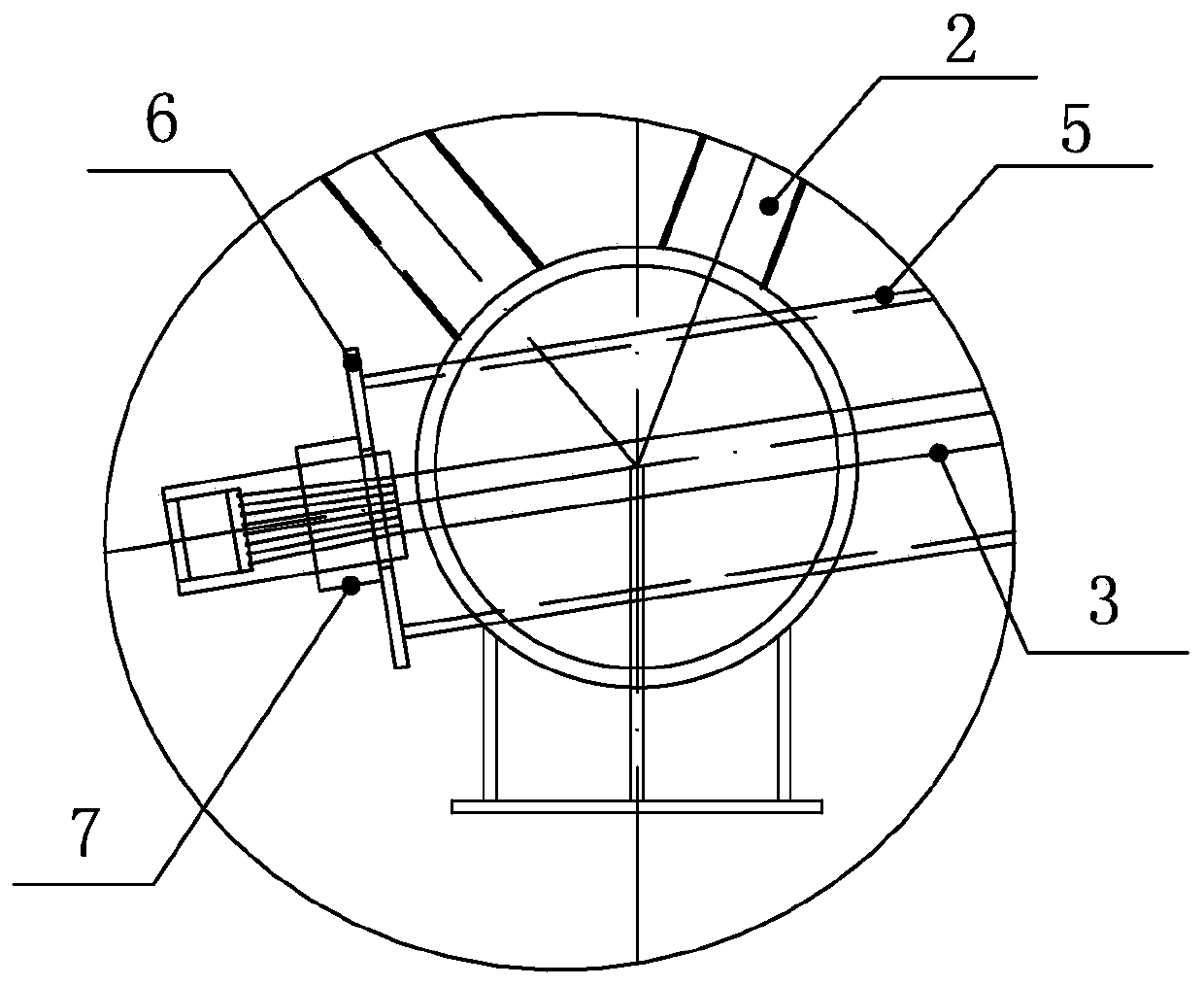

[0040] Such as Figure 1 to Figure 11 Shown, be the prestressed steel cable laying method in the steel pipe body of the present invention, comprise the steps:

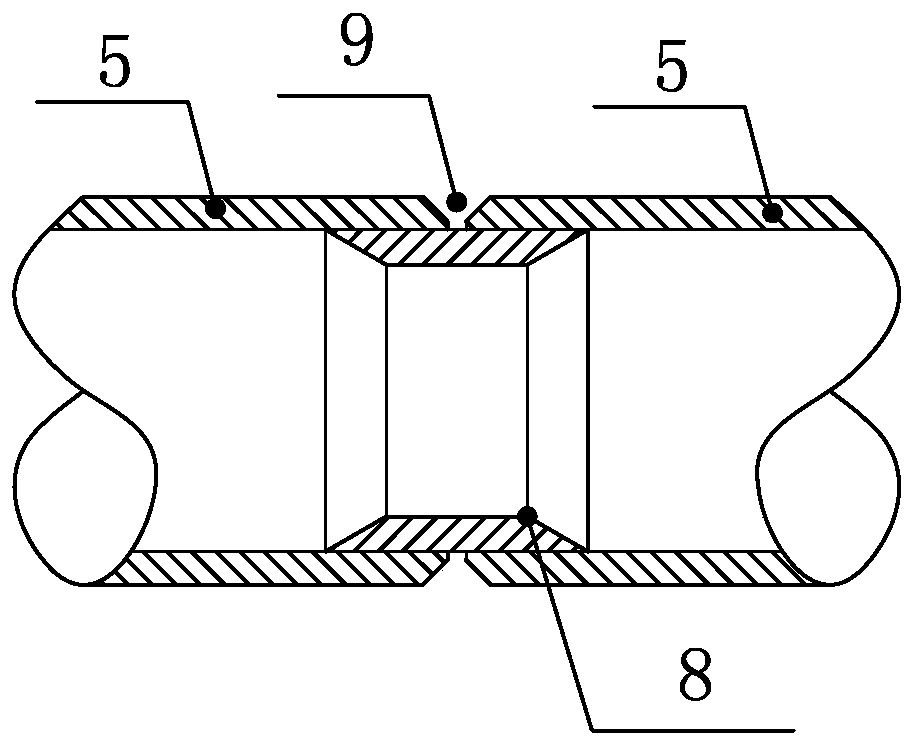

[0041] (a) The raw materials for laying the prestressed steel cables 3 are inspected according to the project management requirements, and the bottom chord 5 is inspected through the ball at the same time.

[0042] The specific ball-passing inspection is to first set a ball-passing steel wire rope 11 inside the lower chord 5, and then hang a steel ball 10 on the end of the lower chord 5. The steel ball 10 is connected with the ball-passing steel wire rope 11. The outer diameter of the steel ball 10 is less than The inner diameter of the lower chord 5 is 2-4mm smaller. Then the steel wire rope 11 for passing the ball is pulled, and the steel ball 10 is drawn out from the other end of the lower chord 5, and the steel ball 10 passes smoothly to illustrate that the inner wall of the lower chord 5 meets the requirements. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com