A method for on-site dynamic balancing of the high-speed output shaft of the reducing and sizing gearbox

An on-site dynamic balancing and output shaft technology, applied in the field of on-site dynamic balancing, can solve the problems of inconvenient application, cumbersome operation, inefficient practical effect, etc., and achieve the effect of convenient on-site application, avoiding potential safety hazards, and facilitating anti-loosening and tightening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

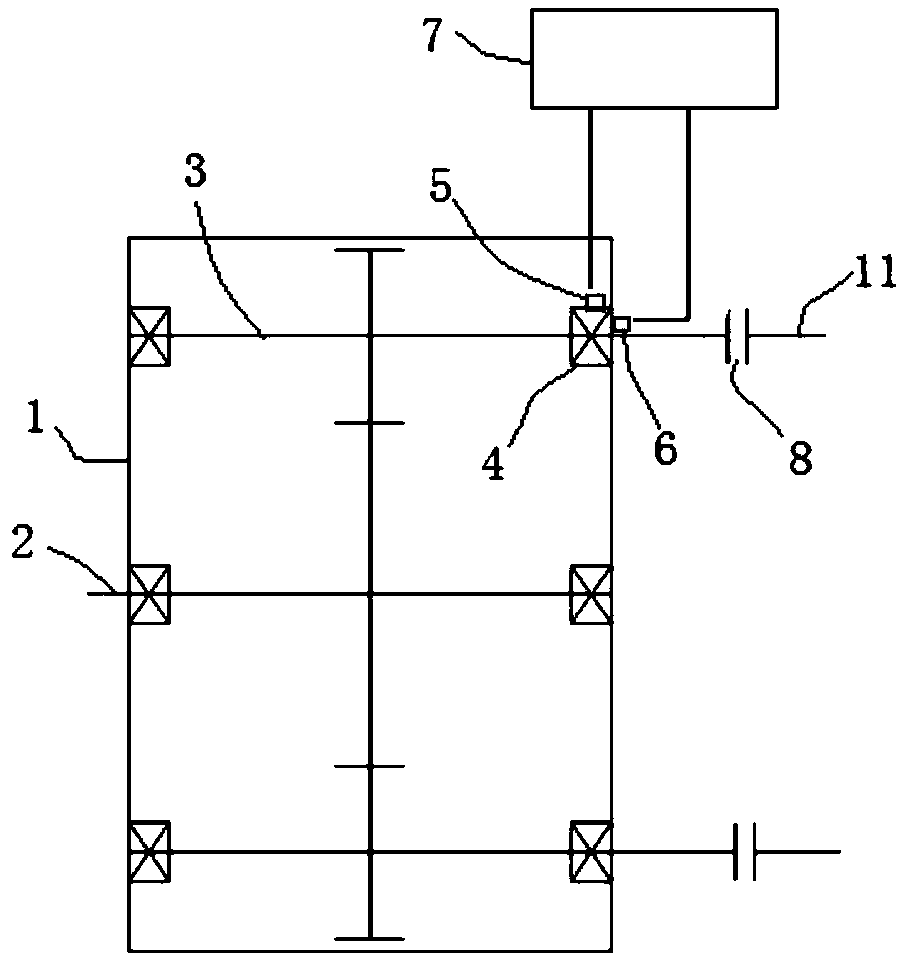

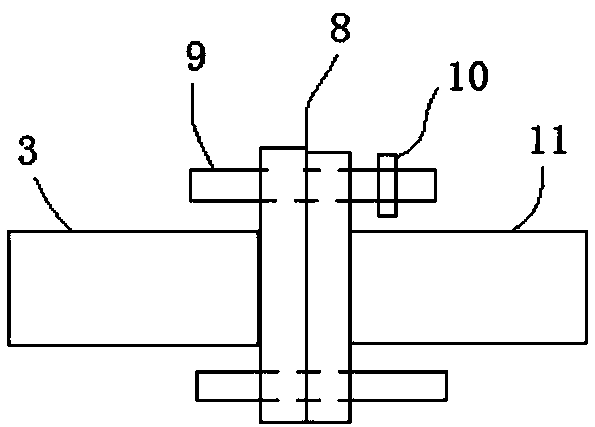

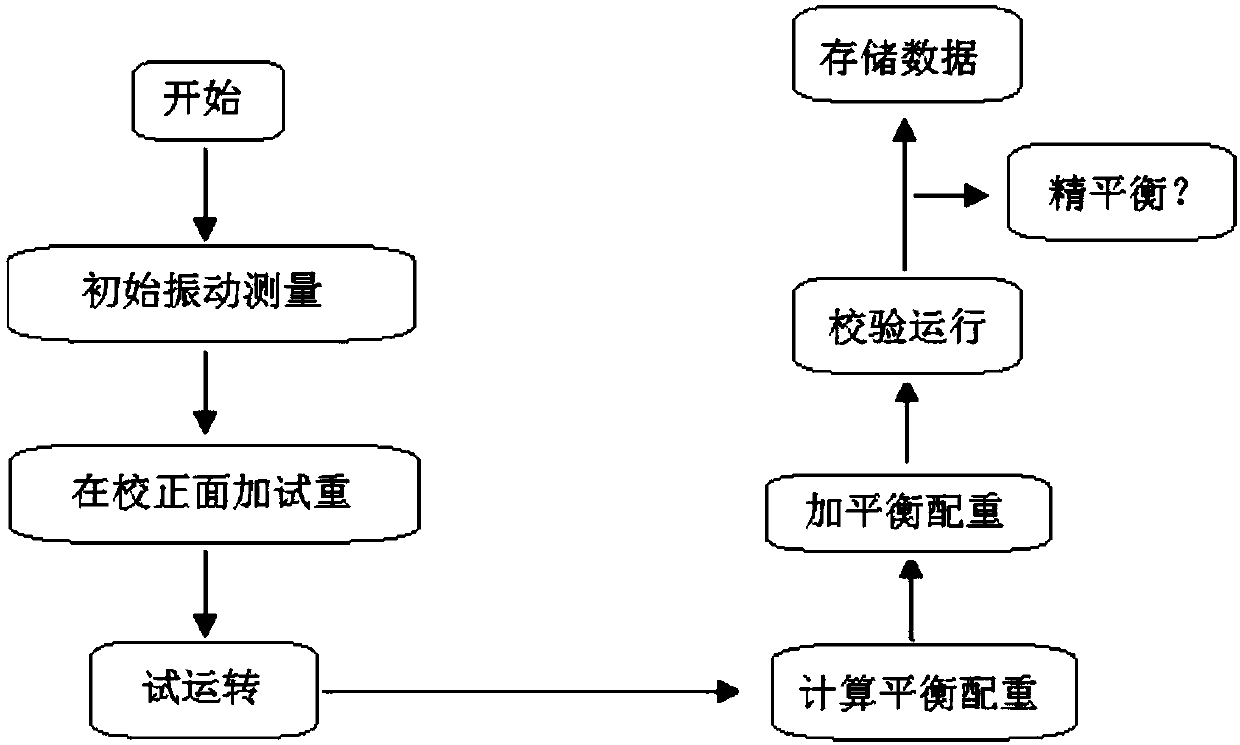

[0045] Such as Figure 1 ~ Figure 4 As shown, the reducing and sizing gearbox 1 is provided with an input shaft 2 and an output shaft 3, and the transmission between the input shaft 2 and the output shaft 3 is carried out through transmission gears, that is, both the input shaft 2 and the output shaft 3 are provided with gears, through Gear meshing transmission; the two ends of the output shaft 3 are fixed with bearing housings 4, the output end of the output shaft 3 is connected with the connecting shaft 11 through the coupling 8, and the connecting shaft 11 is finally connected to the rolling mill, specifically as figure 2 As shown, the coupling 8 includes two opposite flanges, and the bolt rod 9 passes through the two flanges for connection and is fastened by a nut (the nut is not shown in the figure). When used on site, the output shaft 3 is prone to excessive vibration during long-term operation, especially the problem of excessive axial vibration. After repeated inspect...

Embodiment 2

[0064] The on-site dynamic balancing method of a high-speed output shaft of a reducing and sizing gearbox in this embodiment is basically the same as that in Embodiment 1, except that the gamma value in this embodiment is 70°, and the safety factor k is 0.8.

Embodiment 3

[0066] The on-site dynamic balancing method of the high-speed output shaft of the reducing and sizing gearbox in this embodiment is basically the same as that in Embodiment 1, except that the gamma value in this embodiment is 80°, and the safety factor k is 0.9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com