Multipoint sampling photoacoustic spectrometry gas inspection and quarantine device

A technology for inspection and quarantine and photoacoustic spectroscopy, which is applied to the field of multi-point sampling photoacoustic spectroscopy gas inspection and quarantine devices, can solve problems such as inability to efficiently realize multi-point detection, and achieve the effects of improved detection efficiency and accuracy and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

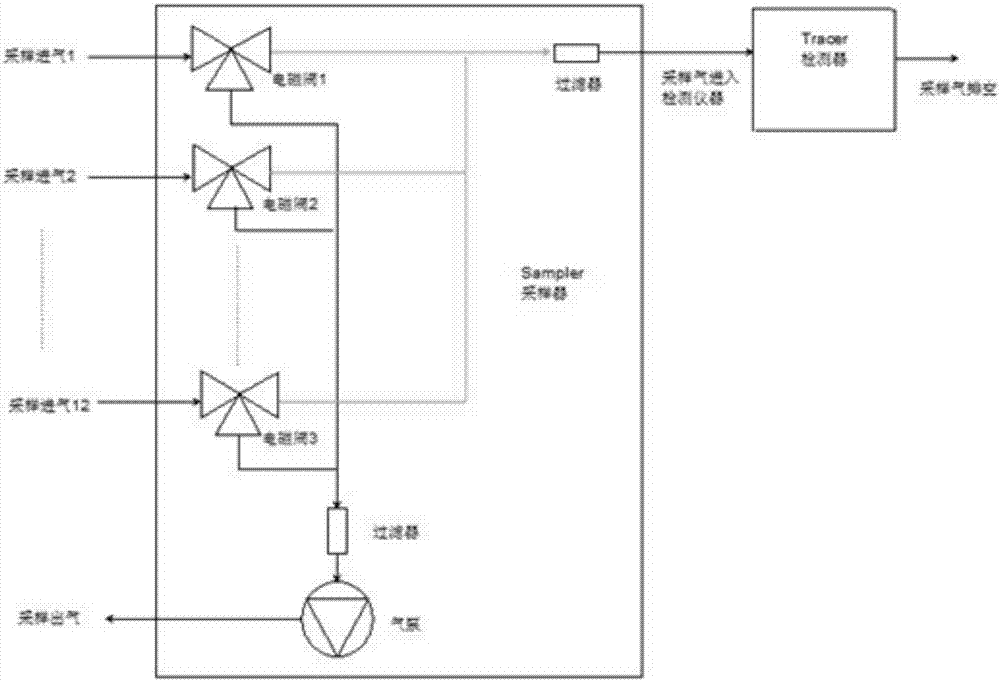

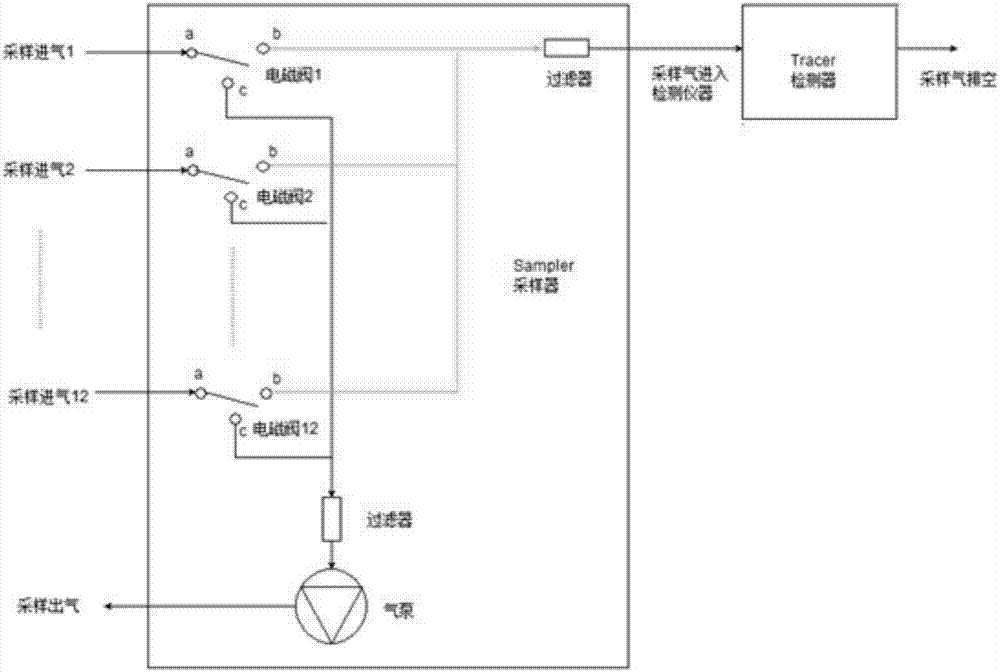

[0029] Such as Figure 1-2 As shown, the multi-point sampling photoacoustic spectroscopy gas inspection and quarantine device proposed by the present invention includes a plurality of sampling air inlets, each air inlet is connected to a solenoid valve, and a passage of the solenoid valve is connected to the air inlet of the rear detector. The other channel connects the air pump in series; set the polling time, which is the time when the sampled gas entering the detector comes from a sampling point, and set each sampling point according to the length of the intake pipe when different sampling points enter the detector for detection polling time;

[0030] When one of the sampling points is polled, the other sampling points are simultaneously sampled through the air pump to keep the sample gas stored in the sampling tube full. When the sampling point is polled, when the polling time is up, it is input to the detector through the solenoid valve. When each sampling point and dete...

Embodiment 2

[0033] Select up to 12 sampling points in the room, and connect each sampling point to the sampling inlet of the sampler. By setting the polling time of each channel, it can be guaranteed that the sampling gas entering the detector at a certain time comes from one sampling point, and other sampling points are also sampling through the air pump, which can ensure that when the next sampling port is detected, The current sampling gas is the gas at the sampling point, which saves detection time, instead of waiting for a long time for the sampling gas to enter the detector like the traditional method. Through multiple sampling points, it can also accurately reflect the concentration distribution of methyl bromide in the room.

[0034] When working normally, the detector uses the principle of photoacoustic spectroscopy to detect the concentration of methyl bromide gas.

[0035] For example, the software controls the solenoid valve 1 so that the sampled intake air 1 enters the detec...

Embodiment 3

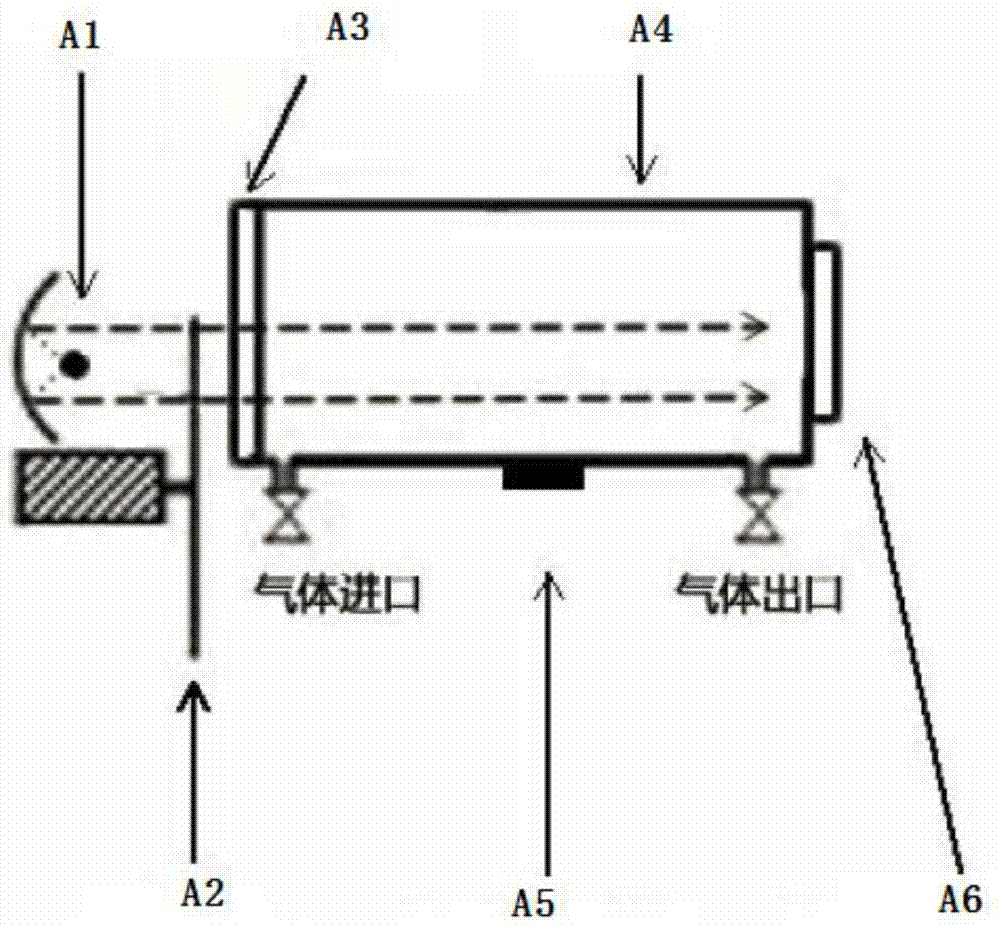

[0040] Furthermore, the photoacoustic spectrum detector of the present invention includes a light source A1, a chopper A2, an optical filter A3, a photoacoustic pool A4, a silicon picophone A5, and an infrared detector A6; The filter A2 and the filter A3 are located at the left end of the photoacoustic cell A4. The photoacoustic cell A4 is divided into upper and lower gas chambers, and an infrared detector A6 is embedded in the right end of the upper gas chamber; The embedded silicon picophone A5, the infrared detector A6 and the silicon picophone A5 are located on the same vertical plane, and the light source A1 is chopped by the chopper A2 and then input through the filter A3 to enter the photoacoustic pool A4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com