Crack detection method based on laser scanning thermal imaging

A crack detection and thermal imaging technology, which is applied in the crack detection field of laser thermal imaging, can solve the problems of difficult detection of tiny cracks and low signal-to-noise ratio of materials with low thermal conductivity, so as to improve the signal-to-noise ratio of crack imaging and reduce the results Interference, take advantage of the full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

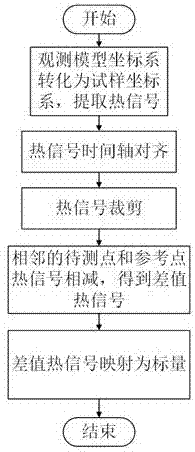

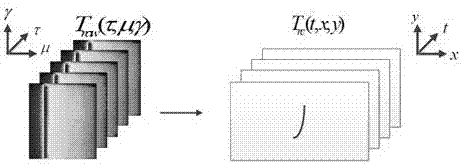

[0024] In order to make the purpose of the present invention, technical solutions and advantages clear, the present invention will be further described below in conjunction with the accompanying drawings:

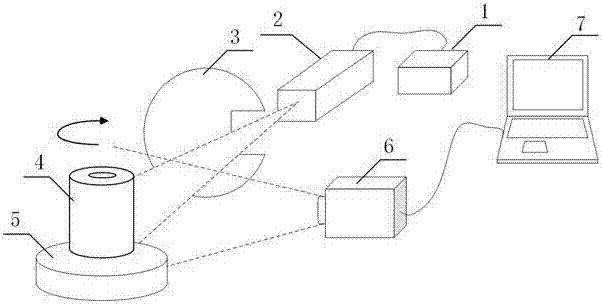

[0025] The detection system of the first embodiment of the present invention is as figure 2 As shown, the experimental object is a cylindrical ferrite device with a diameter of 19 mm, which may produce tiny cracks that are difficult for human eyes to detect due to material and process problems during the production process.

[0026] The detection system includes a laser 1 and its attached probe 2 , a laser shutter 3 , a sample rotating device 5 , an infrared thermal imager 6 , and a computer 7 . The laser 1 is used to scan and heat the cylindrical test piece 4; the laser shutter 3 is used to absorb the laser energy during the laser light preheating stage, so that the laser power can be stabilized; the sample rotating device 5 is used to make the laser and the cylinder unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com