Visual testing device of high-frequency roadbed vibration under plane strain condition

A technology of plane strain and high-frequency vibration, applied in the direction of measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, instruments, etc. Problems such as complex mechanical behavior of media

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

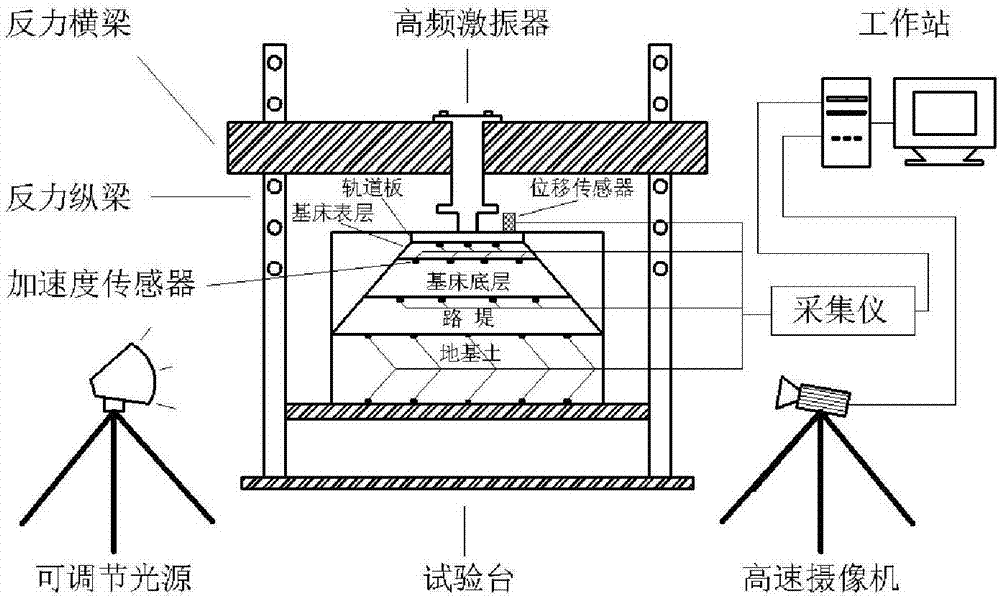

[0024] Such as figure 1 As shown, the device includes three parts: High-frequency loading device: This device can simulate the dynamic load generated by the high-speed train during the running process by adjusting parameters such as loading amplitude and frequency. Visual vibration monitoring and analysis device: This device uses a high-speed camera to record image data, combined with high-speed image processing software, to analyze the model's vibration deformation and internal stress wave propagation rules under high-frequency loads. Energy dissipation monitoring device: This device is composed of acceleration sensor, displacement sensor and data acquisition instrument. Acceleration sensors are placed at the junction of various layers of bulk materials in the subgrade model. By measuring the vibration time-history curves of bulk materials at different interfaces of each layer, the energy of vibration waves can be back-calculated. By comparing the data of each interface, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com