Multifunctional self-cleaning probe plate

A self-cleaning, probe card technology, applied in the field of probe cards and multi-functional self-cleaning probe cards, can solve the problems of cleaning agent residues and bristles fibers falling, so as to prevent inaccuracies and facilitate maintenance and replacement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

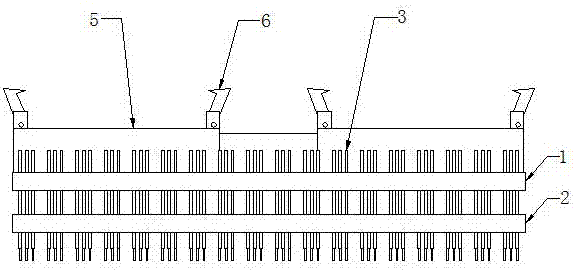

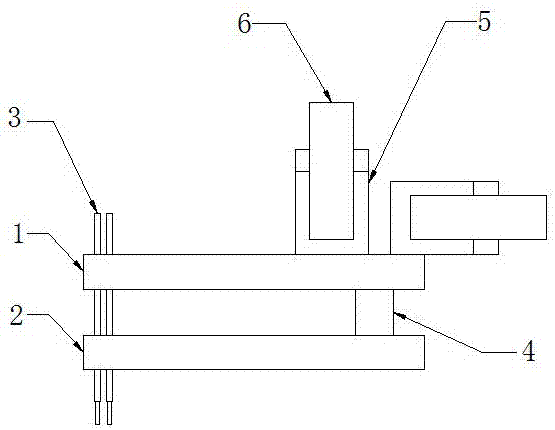

[0028] as attached Figure 1-6 As shown, a multifunctional self-cleaning probe card includes a wiring substrate 1, a support plate 2, and a probe 3. The probe 3 is installed on the wiring substrate 1, and the wiring substrate 1 is fixed and installed through a connecting column 4. On the support plate 2, three slots 5 are installed on the wiring substrate 1, connecting fasteners 6 are arranged on both sides of the mouth of the slot 5, and binding posts 7 are arranged in the slot 5. The connecting post 7 is connected to the probe 3 at the corresponding position through the circuit on the wiring substrate 1; through holes 8 are set at the corresponding positions of the wiring substrate 1 and the support plate 2, and a compressed air duct is installed in the through holes 8 9. The air outlet end of the compressed air duct 9 is connected to a transverse duct 10 , and a gas nozzle 11 is arranged on the transverse duct 10 , and the gas nozzle 11 is arranged at a position opposite to...

Embodiment 2

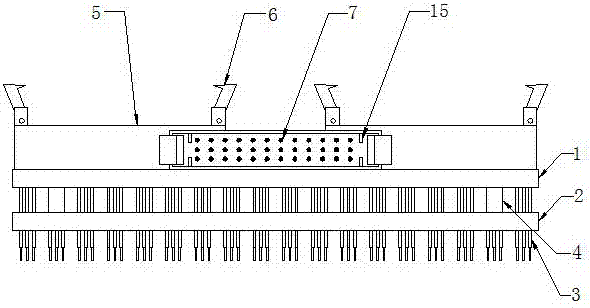

[0032] as attached Figure 1-8 As shown, a multifunctional self-cleaning probe card includes a wiring substrate 1, a support plate 2, and a probe 3. The probe 3 is installed on the wiring substrate 1, and the wiring substrate 1 is fixed and installed through a connecting column 4. On the support plate 2, three slots 5 are installed on the wiring substrate 1, connecting fasteners 6 are arranged on both sides of the mouth of the slot 5, and binding posts 7 are arranged in the slot 5. The connecting post 7 is connected to the probe 3 at the corresponding position through the circuit on the wiring substrate 1; through holes 8 are set at the corresponding positions of the wiring substrate 1 and the support plate 2, and a compressed air duct is installed in the through holes 8 9. The air outlet end of the compressed air duct 9 is connected to a transverse duct 10 , and a gas nozzle 11 is arranged on the transverse duct 10 , and the gas nozzle 11 is arranged at a position opposite to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com