Extraction and analysis method and device for section contour line of special-shaped workpiece

A special-shaped workpiece and analysis method technology, applied in measurement devices, image analysis, using optical devices, etc., can solve the problems of unverifiable machining accuracy, hidden dangers in application, and inability to perform measurement, so as to reduce the amount of data, avoid inaccuracy, The effect of eliminating human error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

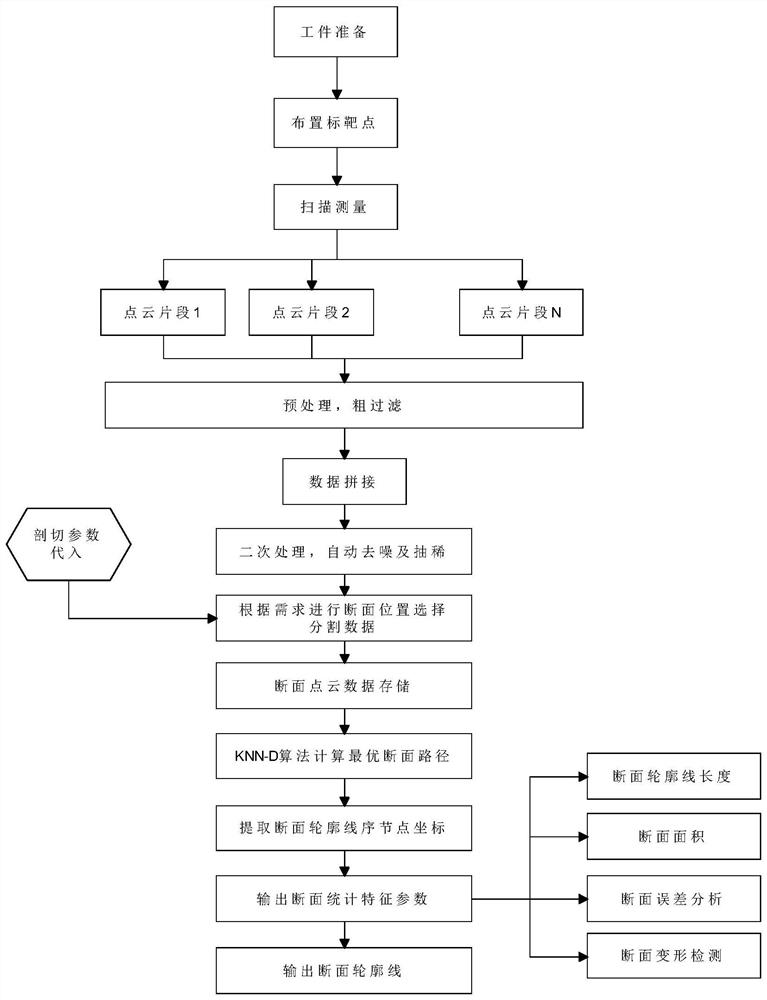

[0080] Such as figure 1 As shown, a method for extracting and analyzing the profile of a special-shaped workpiece section provided in this embodiment includes the following steps:

[0081] S1: Pretreatment of the surface of the workpiece to be measured, the mirror material with strong reflection can be properly sprayed to reduce the output of noise, mark the measured target point on the contour line of the workpiece section, and determine the position P of the laser scanner 0 The coordinates (x 0 ,y 0 ,z 0 ) and the position P of the measured target point i The coordinates (x i ,y i ,z i ), there are n measured target points on the contour line of the workpiece section, i=1,2,...,n;

[0082] S2: Use a laser scanner to automatically scan and collect data from multiple angles of the workpiece to be measured, and obtain the three-dimensional scattered point data of n measured target points on the cross-sectional surface of the workpiece, as well as n points on the cross-se...

Embodiment 2

[0110] The difference between this embodiment and Embodiment 1 or Embodiment 2 is that before the data boundary fitting and data splicing using the least squares method in step S3, the boundary endpoints of the fitted sphere formed by the measured target points are constructed. The method for judging whether it is a boundary triangle includes the following steps:

[0111] M1: Use a triangle with the smallest circumscribed empty circle with a radius r formed by any three points on the fitted sphere center cross-section circle with parameters a, b, c and d to calculate the side length l and semiperimeter s of the triangle :

[0112]

[0113]

[0114] Among them, (x 1 ,y 1 ,z 1 ) and (x 2 ,y 2 ,z 2 ) is the three-dimensional coordinates of any two points in the triangle;

[0115] M2: Use Heron's formula to calculate the triangle area S formed by any three points on the cross-sectional circle of the center of the fitting sphere:

[0116]

[0117] M3: According to ...

Embodiment 3

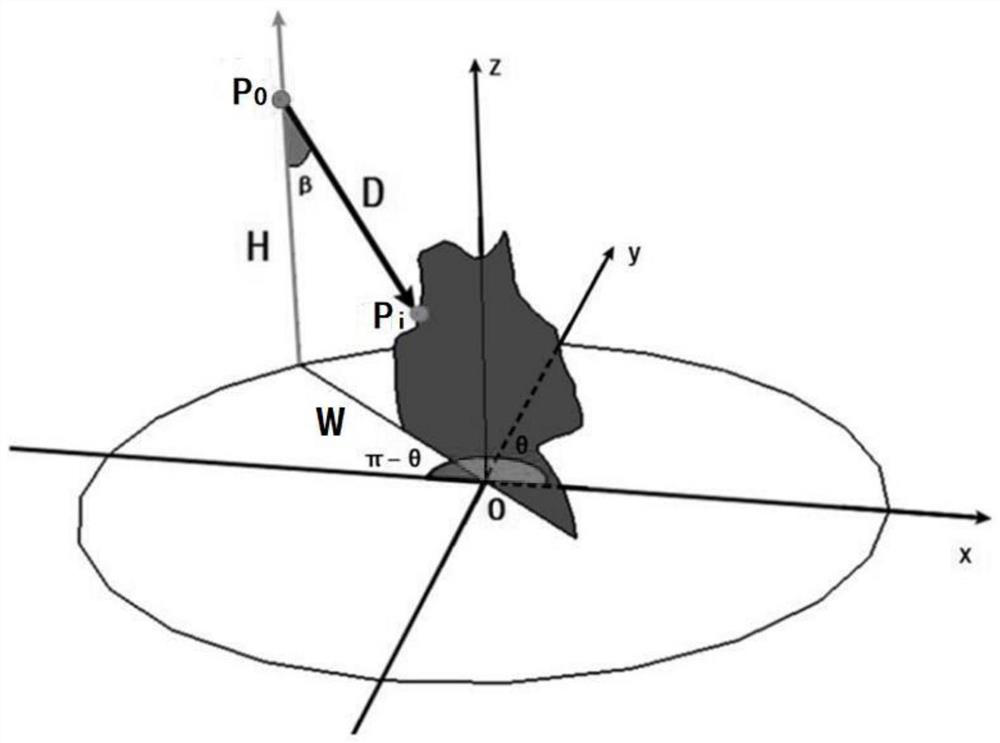

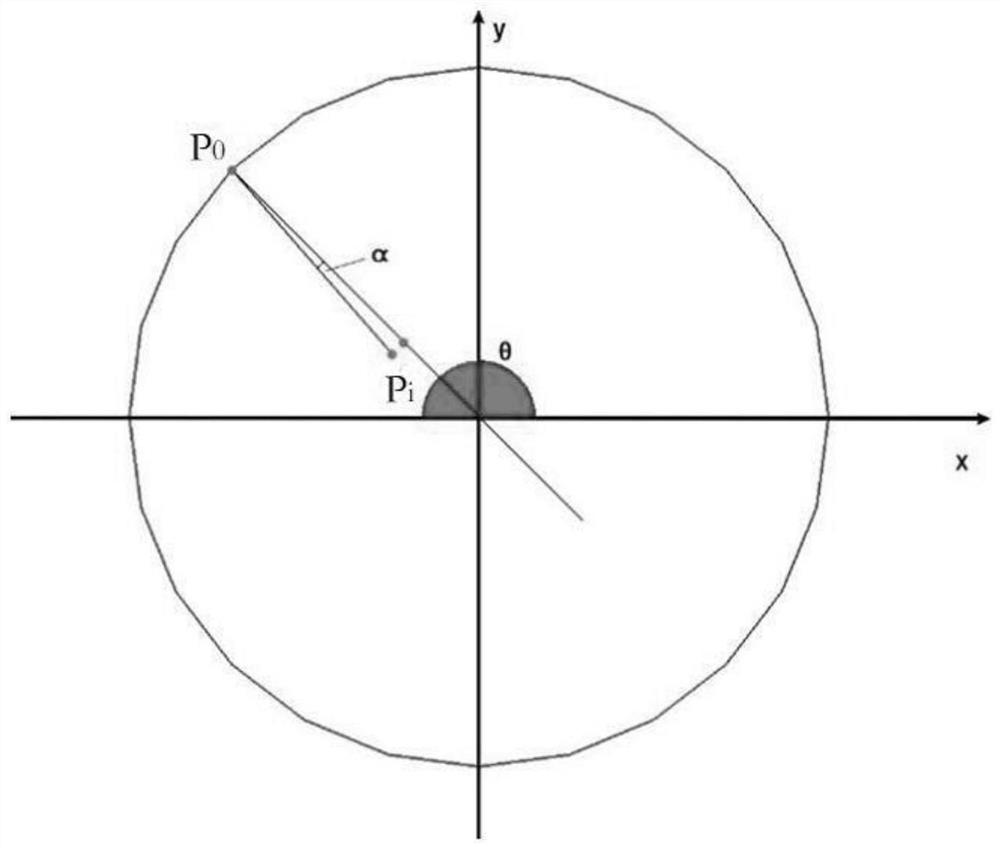

[0121] like figure 2 As shown, the difference between this embodiment and embodiment 2 is only the position P of the laser scanner in the S1 step 0 Coordinates (x 0 ,y 0 ,z 0 )Calculated as follows:

[0122] x 0 =W×cosθ

[0123] x 0 =W×sinθ

[0124] z 0 =H

[0125] Among them, W is the radius of the light source center of the laser scanner equipment relative to the origin of the center of the orbit around the scanner, H is the height of the light source center of the laser scanner equipment relative to the flat base plane of the scanning area, θ is the center of the light source of the laser scanner equipment along the scanner Instantaneous angle during orbital motion;

[0126] The position coordinates of the measured target point (x i ,y i ,z i ) is calculated as follows:

[0127] x i =(W-D×sinβ)×cosθ;

[0128] the y i =(W-D×sinβ)×sinθ;

[0129] z i =H-D×cosβ;

[0130] Among them, D is the distance between the center of the light source of the laser scann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com