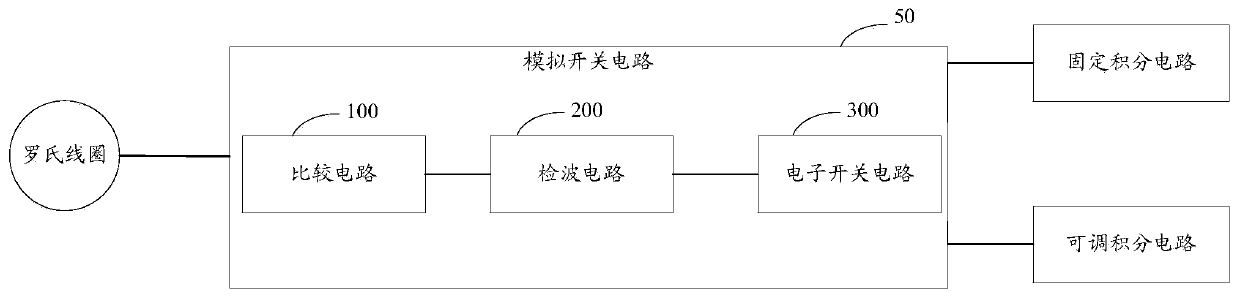

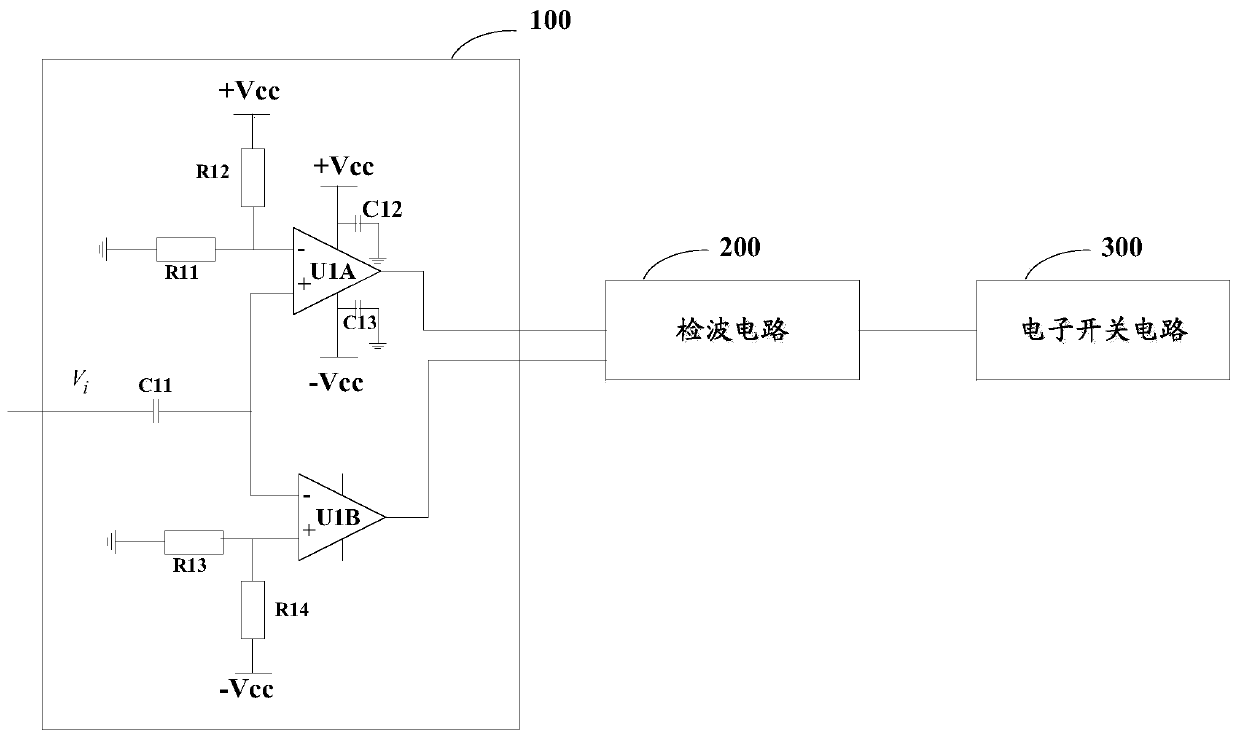

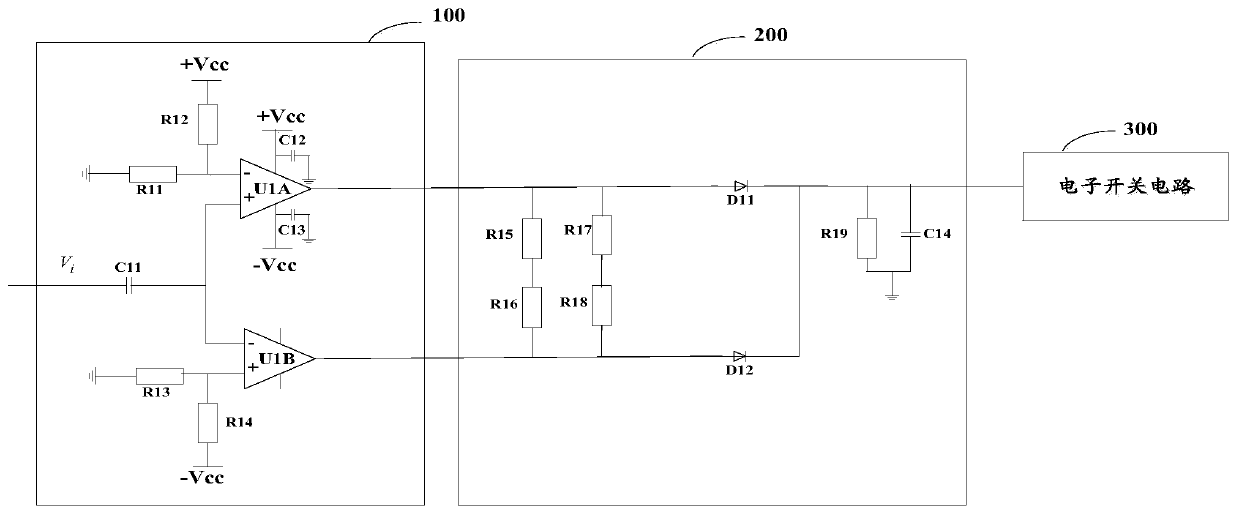

Analog switch circuit and secondary current detection system of inverter resistance welding machine

A technology for simulating switching circuits and resistors, applied in the field of welding current detection of inverter DC resistance welding machines, can solve problems such as uncontrollable integral capacitance, achieve the effect of improving measurement accuracy and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

application example 1

[0078] Taking the JYD-04AL intermediate frequency inverter resistance welding machine as a test prototype, the solution of the present invention is introduced in detail. The inverter frequency of the prototype is 4kHz, and the effective value of the rated output current is 4kA. The welding current waveform actually output by the prototype, that is, the current signal to be detected by the present invention is as follows: Figure 9 As shown, it can be seen from the figure that the measured object is a pulsating DC signal, and the pulsating frequency is 8kHz. This application example uses a flexible Rogowski coil with the following parameters for measurement: coil ratio 85mV / kA (50Hz), amplitude accuracy ±0.5% rdg (25°C), maximum response time 1μs, bandwidth 2Hz-100kHz. The original welding current of the prototype is input to the input end of the Rogowski coil in the secondary current detection system of the inverter resistance welding machine. Such as Figure 10 As shown, wh...

application example 2

[0080] The welding current is 2kA, the welding time is 2s, and the compensation effect is compared. Such as Figure 11 , wherein, 1, 2, and 3 in the figure refer to channel 1, channel 2 and channel 3 respectively; channel 1 represents the secondary current signal measured when uncompensated; channel 2 represents the secondary current detection using the inverter resistance welding machine of the present invention The secondary current signal measured by the system; Channel 3 represents the secondary current signal measured by the Hall current sensor. It can be seen that the waveform output without compensation has obvious integral drift in the integration time of nearly two seconds, and the waveform is seriously distorted. The waveform after compensation is consistent with the trend of the actual welding current waveform, and the compensation effect is remarkable.

application example 3

[0082] Test the linearity of the secondary current detection system of the inverter resistance welding machine in the present invention. Calibrate the current detection device when the current is 4.00kA, so that the effective value of its output voltage is 4V. Then test the current detection device when the actual welding current is 3.70kA, 3.40kA, 3.10kA, 2.80kA, 2.50kA, 2.20kA, 1.90kA, 1.60kA, 1.30kA, 1.00kA and 0.70kA, and the linearity of the measurement results Degree curve such as Figure 12 shown. The linearity of the measurement results is 1.004, meeting the measurement requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com