Method for preparing MgO/carbon composite adsorbing material by using lemon pulp and magnesium slag through one-step method

The technology of carbon composite material and adsorption material is applied in the field of preparing MgO/carbon composite adsorption material, which can solve the problems of crops, human and livestock being harmful, and achieve the effects of low cost, high adsorption efficiency and light weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

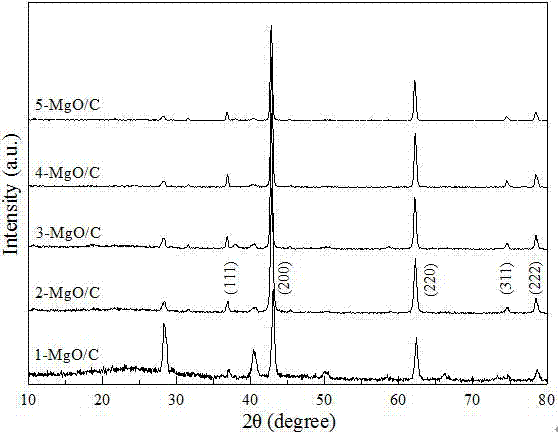

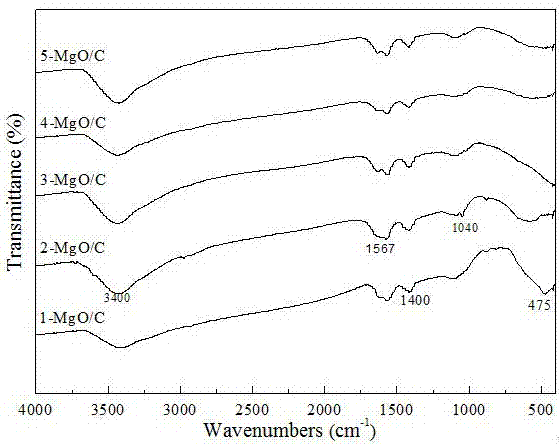

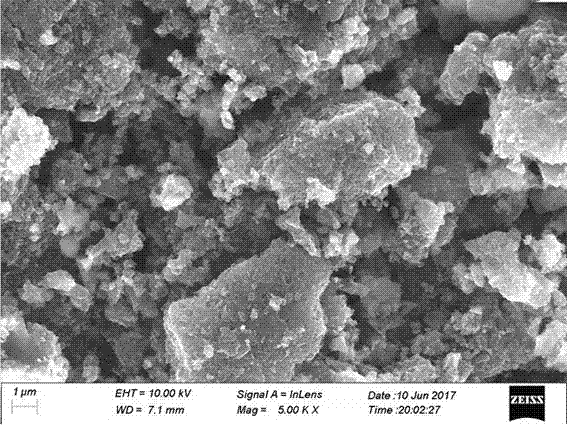

Embodiment 1

[0032] Weigh 10g of lemon residue and add it to a beaker filled with 300mL of magnesium residue solution with a concentration of 10g / L, then electric stir in a water bath at 80°C until most of the solvent evaporates, then place the beaker in an oven and dry at 60°C for 3h , collect samples at N 2 In an atmosphere furnace with a flow rate of 5mL / min, the temperature was raised to 400°C at a rate of 5°C / min and roasted for 5h to obtain a MgO / carbon composite material, which was denoted as 1-MgO / carbon composite material.

Embodiment 2

[0034] Weigh 10g of lemon residue and add it to a beaker filled with 300mL of magnesium residue solution with a concentration of 15g / L, then electric stir in a water bath at 85°C until most of the solvent evaporates, then place the beaker in an oven and dry at 60°C for 3h , collect samples at N 2 In an atmosphere furnace with a flow rate of 8mL / min, the temperature was raised to 500°C at a rate of 3°C / min and roasted for 5 hours to obtain a MgO / carbon composite material, which was denoted as 2-MgO / carbon composite material.

Embodiment 3

[0036]Weigh 10g of lemon residue and add it to a beaker filled with 300mL of magnesium residue solution with a concentration of 20g / L, then electric stir in a water bath at 75°C until most of the solvent evaporates, then place the beaker in an oven and dry at 60°C for 3h , collect samples at N 2 In an atmosphere furnace with a flow rate of 10mL / min, the temperature was raised to 600°C at a rate of 8°C / min and roasted for 4 hours to obtain a MgO / carbon composite material, which was denoted as 3-MgO / carbon composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com