Technology for finely separating materials and sand in laminar flow

A technology of fine separation and technology, which is applied in the field of laminar flow material sand fine separation, can solve the problems such as the inability to separate feces from sand fines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

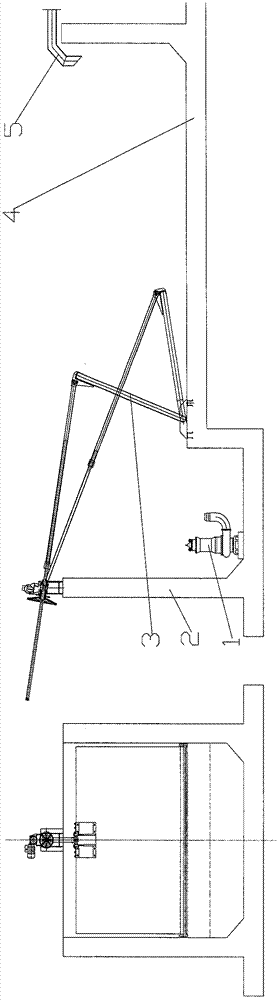

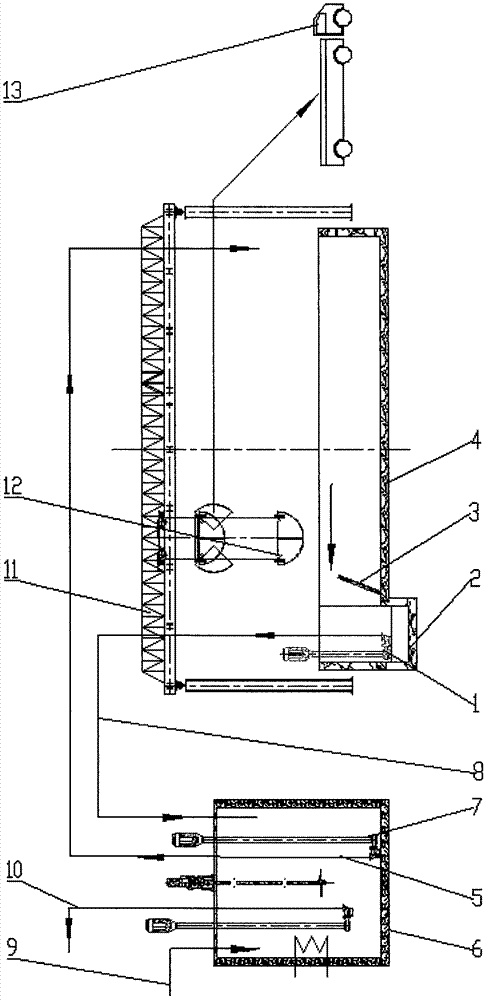

[0009] The specific implementation manners involved in the present invention will be described below in conjunction with the accompanying drawings.

[0010] The fine separation technology of laminar flow material and sand provided by the present invention is to carry out fine separation of the sand-containing material that has been roughly separated in the sand collection tank in the sand washing tank, and first use the sand-containing material lifting pump 7 to lift the sediment in the sand collection tank The sand-containing material at the bottom of the pool 6 is pumped into the inlet of the sand washing tank. Before feeding the sand washing tank, the upper end of the gate 3 is adjusted to the highest position. After the material enters and settles for a certain period of time, the gate is lowered to the second height. , the sand-free clarified fecal liquid on the uppermost layer of the sand washing tank overflows the gate and enters the flushing pool 2, and then settles for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com