Magnetic fusion motor

A technology of rotary motor and linear motor, applied in the new field of electromagnetic field, can solve the problems of complex structure, huge cost, construction of roadbed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

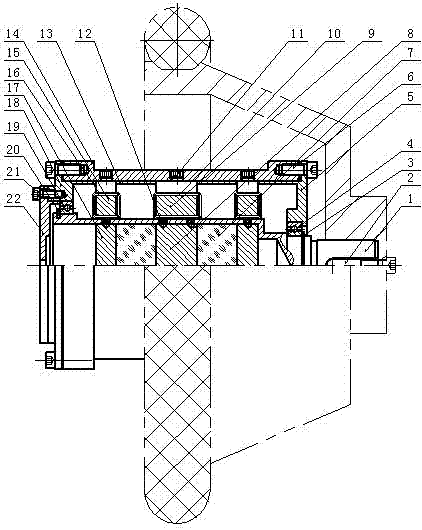

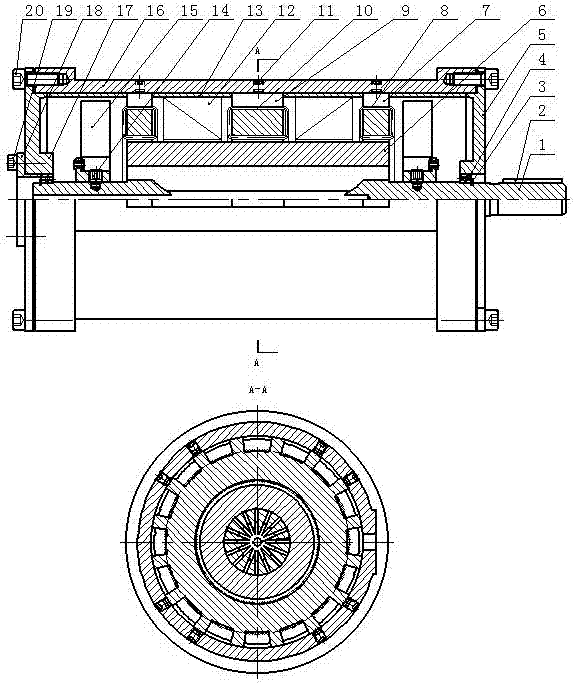

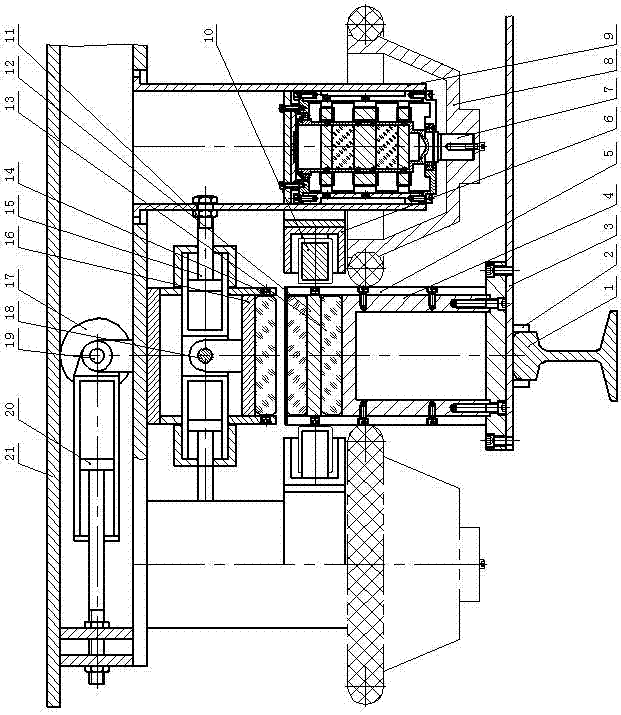

Image

Examples

Embodiment Construction

[0025] The rotor, iron core, and casing of the magnetic fusion motor are made of carbon steel. The cross-sectional area of the armature winding wire is as large as possible to reduce heat generation. If necessary, a fan is installed on the rotating shaft.

[0026] The permanent magnets of permanent magnet fusion motors are made of high energy product permanent magnet materials, such as neodymium iron boron (Nd-Fe-B). The rotating shaft is placed vertically to facilitate the magnetic levitation of the rotating shaft of the magnetic fusion rotating electrical machine.

[0027] The number of turns of the pair of excitation winding coils of the electromagnetic fusion motor is as large as possible, and the direct current or alternating current of opposite rotation direction is passed respectively, so as to obtain a sufficiently large axial magnetic field in opposite direction.

[0028] The steering of the rotor can be controlled using a bridge circuit connected to the armature wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com