Liquid espresso concentrate

A concentrate and coffee technology, applied in the direction of coffee, coffee extraction, roasting coffee, etc., can solve problems such as coffee difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

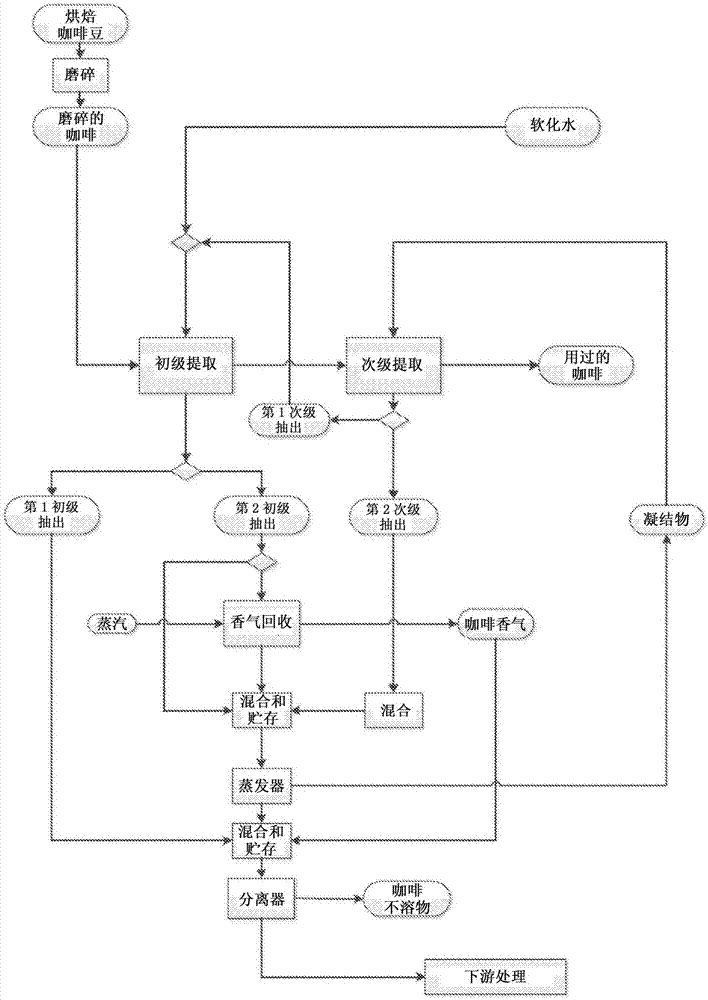

Method used

Image

Examples

Embodiment 1

[0157] The principles of the invention were demonstrated on an industrial scale in a series of diffusion cell arrays of fixed bed coffee extractors. A coffee blend consisting of 60% washed Arabica and 40% unwashed Arabica has been roasted in a batch roaster at 9:00 minutes with reduced roasting air temperature . The degree of torrefaction that had been applied resulted in a torrefaction loss of 16.5% by weight. The moisture content of the roasted coffee beans was 2.9% by weight.

[0158] Just prior to coffee extraction, the roasted coffee beans were ground to an average grind size of 1.9 mm (XMa min was defined according to the calculation given above).

[0159] The chamber was loaded 100% with ground coffee and no wetting of the ground coffee should be applied prior to extraction.

[0160] The primary extraction was performed countercurrently to sodium demineralized water, with the feed water being introduced into the percolator in upflow, with a feed temperature of 95°C. ...

Embodiment 2

[0172] A coffee concentrate was manufactured following the procedure of Example 1 with the specific settings outlined in Table 3 below. Coffee blend used: 60 wt.% Arabica washed; 40% Arabica unwashed.

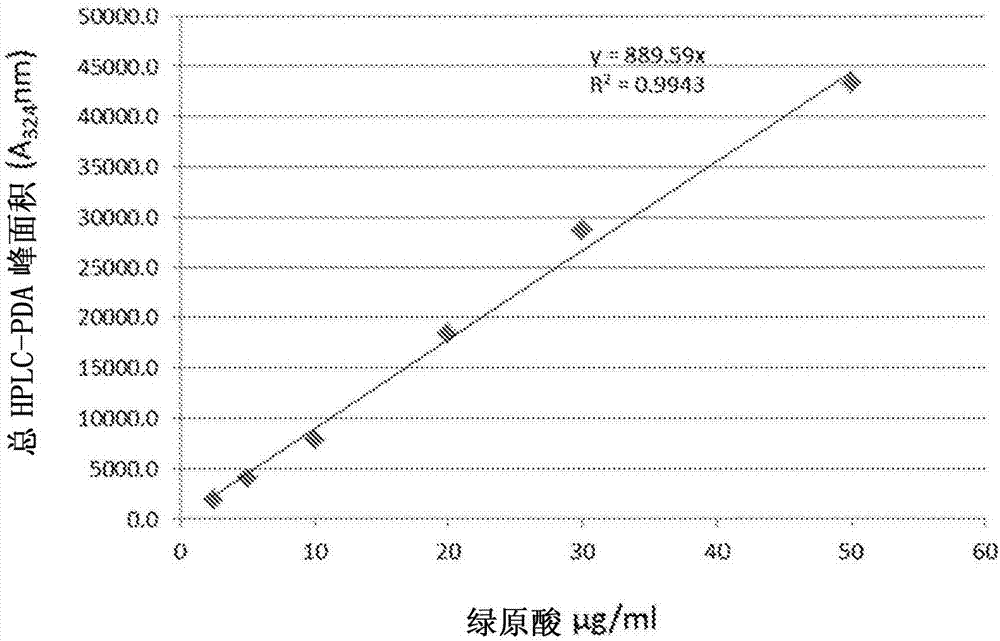

[0173] 1 - CQL content of 559 mg per kg dry solid matter for the liquid concentrate obtained according to Example 2A and 622 mg per kg dry solid matter for the liquid concentrate obtained according to Example 2B.

[0174] The Y process model values calculated based on partial least squares discriminant analysis of the six identified flavor markers, as defined in this specification, are as follows for Examples 2A and 2B:

[0175] 2A: 0.827

[0176] 2B: 0.682

Embodiment 3

[0177] Embodiment 3 (reference example)

[0178] A coffee concentrate was prepared according to the teaching in WO 2007 / 043873 with a coffee blend nearly identical to that of Example 2 (65 wt.% Arabica washed; 35% Arabica unwashed card), and the specific settings are summarized in Table 3 below. The size of the coffee grounds (Martin diameter minimum as defined in this specification) is 3.6 mm. The mass transfer Fourier number was 0.20. The ratio of the yield obtained in the first primary extraction to the yield obtained in the total extraction was 13.9.

[0179] For the liquid concentrate obtained, the 1-CQL content is 375 mg per kg of dry solid matter. As defined in this specification, the Y process model value calculated based on partial least squares discriminant analysis of the six identified flavor markers was 0.329.

[0180] table 3

[0181]

[0182] Table 4

[0183]

[0184] table 5

[0185]

[0186] Table 6

[0187]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com