Preparation process of cold-pressed tea seed oil

A preparation process and technology of tea seed oil, which are applied in the direction of oil/fat refining, edible oil/fat, and oil/fat production, etc., can solve problems such as loss of aroma of camellia oleifera, and achieve the effects of strong aroma, stable process and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] A kind of cold pressing tea seed oil preparation technology is characterized in that, comprises the following steps:

[0023] (1) Put the tea seeds into the cold storage for 10-12 hours, the temperature of the cold storage is -15--10°C; after taking them out, send them to the tunnel drying room for drying, the temperature of the drying room is 50-60°C , the time is 3-4 hours; repeated several times; until the water content of tea seeds is 5%;

[0024] (2) Pulverizing the Camellia oleifera seed, separating the shell and kernel;

[0025] (3), adding water for tempering, passing steam into the Camellia oleifera seed powder until the water content of the Camellia oleifera seed powder is 10-12%;

[0026] (4) Pressing, enter the press material at less than 35°C, and use a twin-screw oil press to press out the oil;

[0027] (5) Fine filtration, using a bag filter to filter until the cold-pressed oil is clear and transparent. It is high-grade cold-pressed tea seed oil.

[0...

PUM

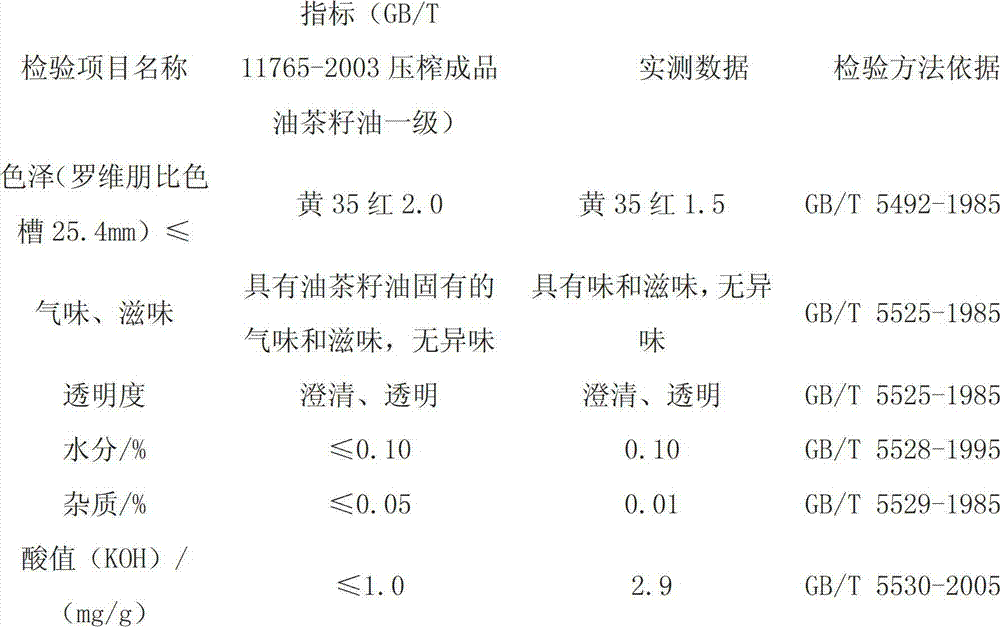

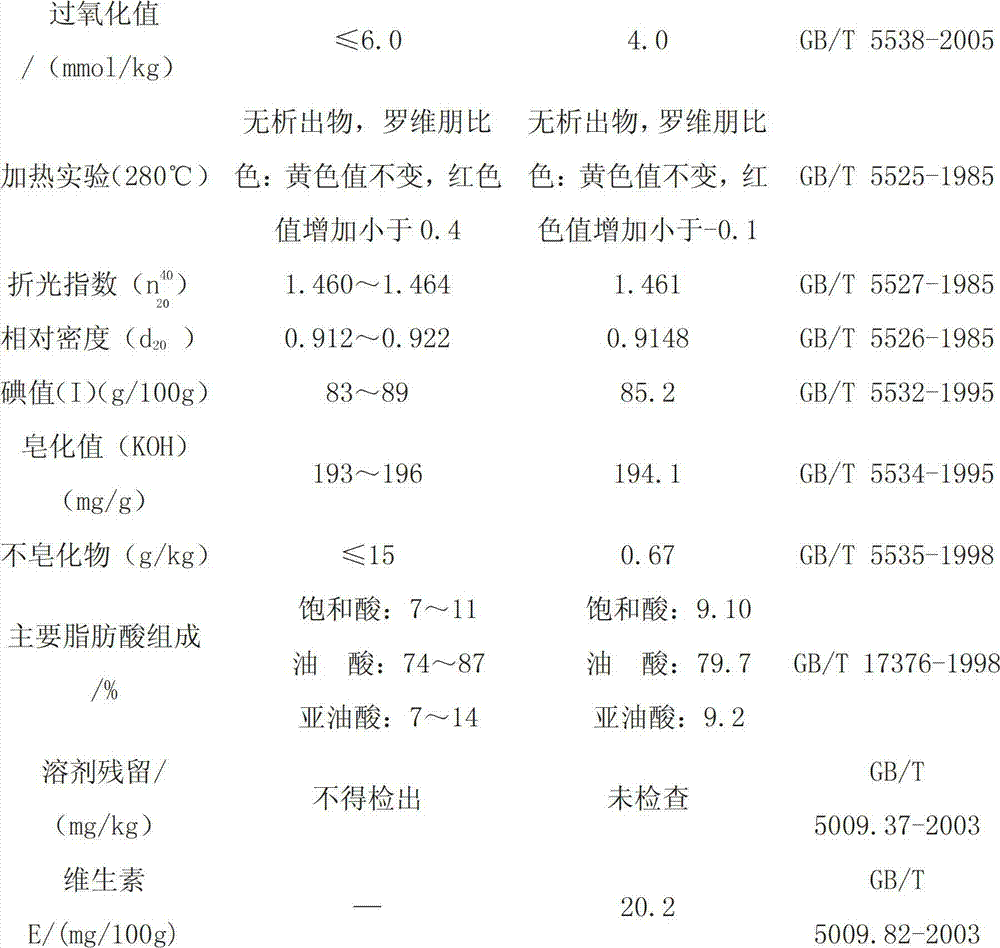

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| peroxide value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com