A kind of topping machine and its topping mechanism

A topping machine and budding technology, applied in agricultural machinery and tools, horticulture, agriculture, etc., can solve the problems of small planting scale, high production cost, high labor intensity, etc., and achieve high topping efficiency and good topping effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

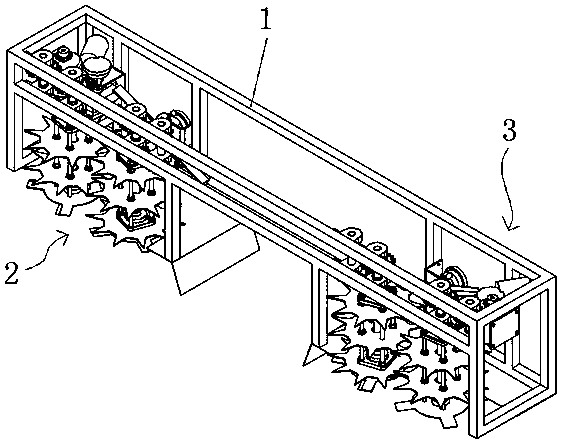

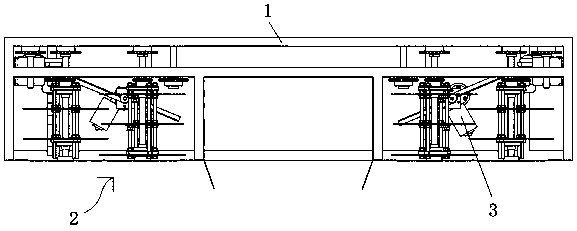

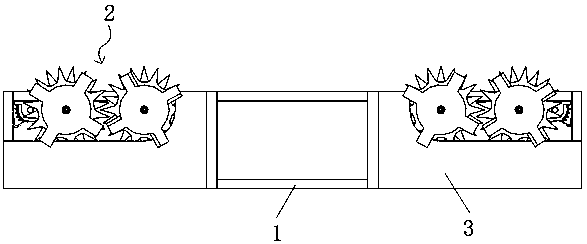

[0047] The specific embodiment 1 of a topping machine of the present invention includes a rack 1. The inside of the rack 1 is divided into three spaces along the left and right directions, and a set of topping modules are provided in the spaces on the left and right sides. The topping module includes a topping mechanism 2 and a top bud cleaning mechanism 3. In addition, the frame 1 is also provided with a casing for protecting the topping module, wherein the casing is provided with an inlet for tobacco plants at the entrance of the corresponding topping mechanism 2, and the corresponding top bud cleaning mechanism The outlet of 3 is provided with a discharge port for the top buds to be cut off, and the discharge ports of the top bud cleaning mechanism of the topping module on the left and right sides are opposite to each other. The specific structure of the rack 1 and its internal devices is as Figure 1 to Figure 3 As shown, in order to facilitate the observation of the intern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com