Chicken rearing equipment

A kind of equipment and chicken cage technology, applied in the poultry industry, application, poultry cage or house, etc., can solve the problems that the dirt cannot be removed in time, unfavorable to the healthy breeding of chickens, and unfavorable breeding environment, so as to improve the scale of breeding and economic benefits , Improve the economic benefits of breeding and increase the effect of breeding density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with embodiment.

[0027] The present invention is achieved like this, and chicken raising equipment comprises 5 systems, as follows:

[0028] (1) Manure cleaning system;

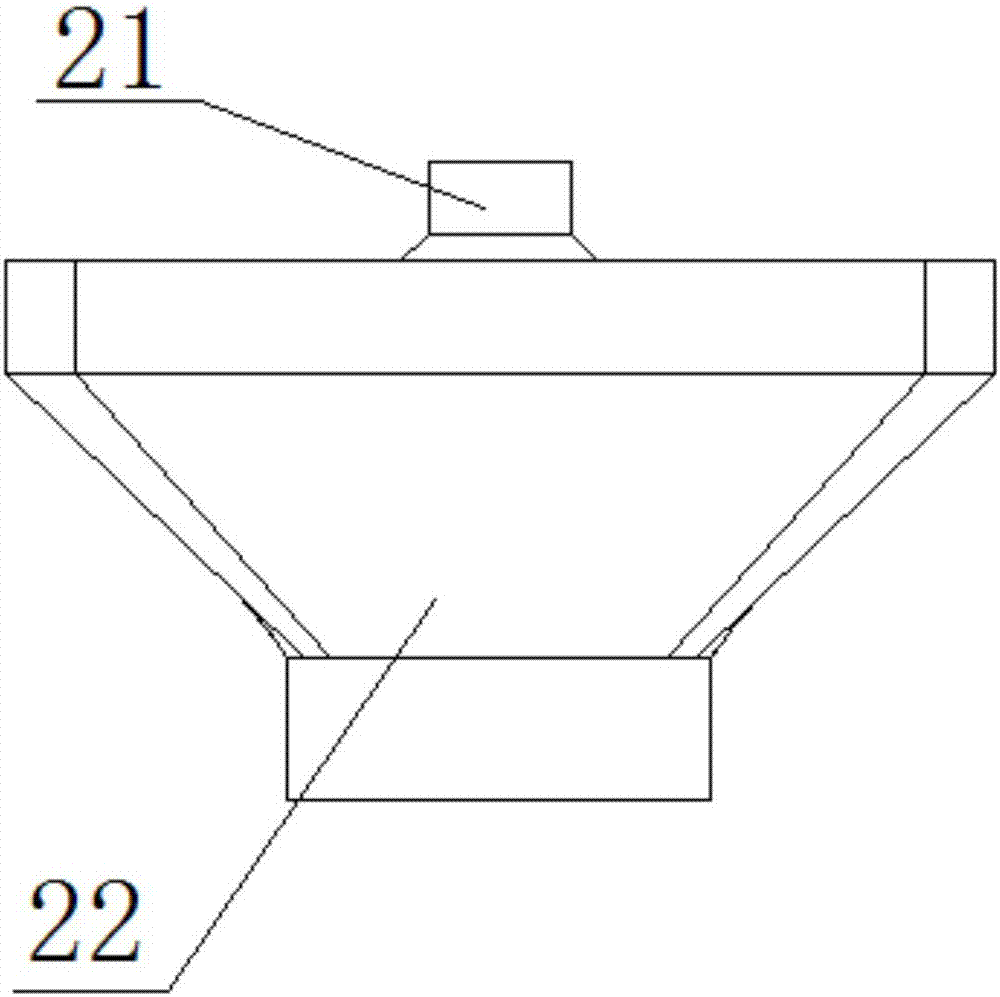

[0029] (2) Feeding feed system;

[0030] (3) Feeding water system;

[0031] (4) chicken coop;

[0032] (5) Fixed bracket system.

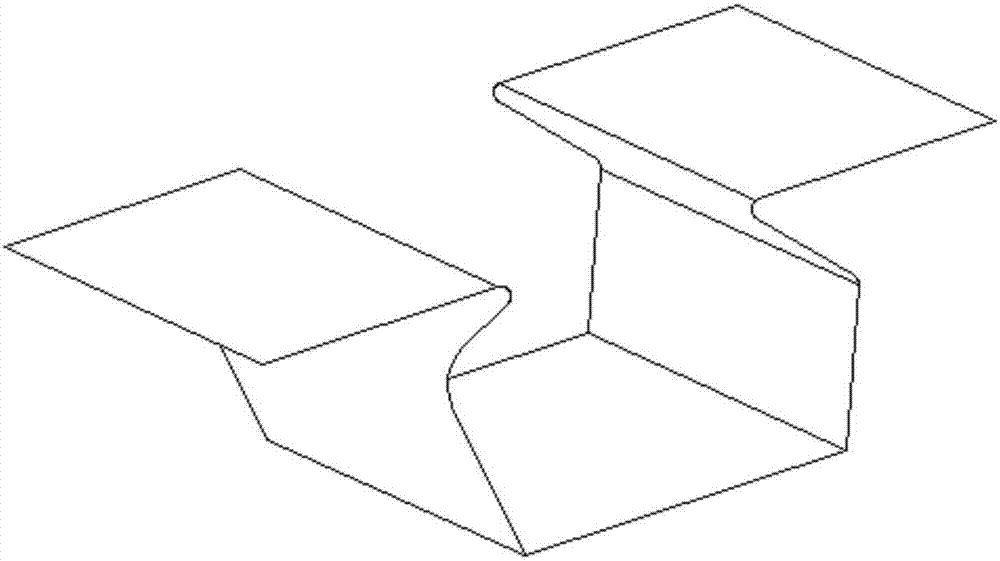

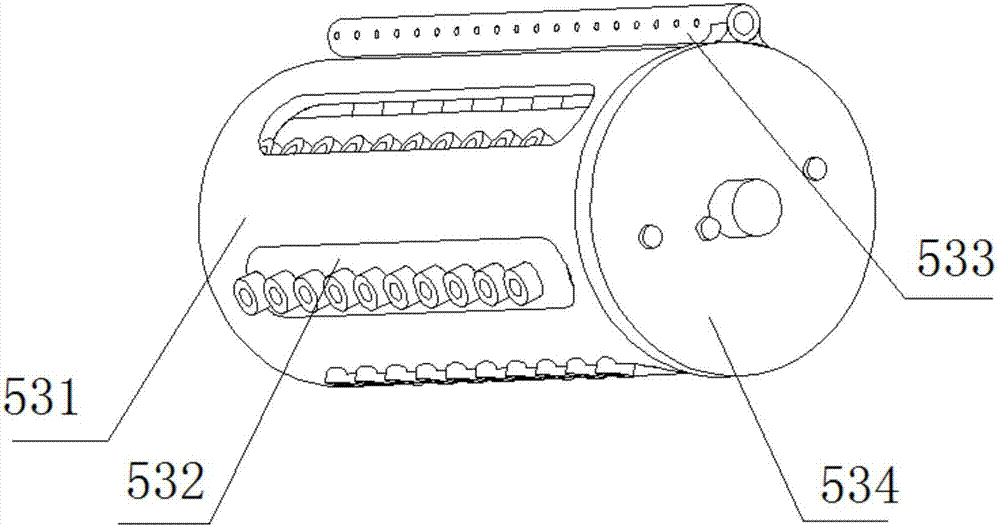

[0033] 1. If figure 1 and figure 2 As shown, the manure cleaning system is to timely clean out feces, feathers and other dirt during the breeding process to maintain the hygienic conditions of the breeding environment, which specifically includes the following two aspects:

[0034] (1) Belt-type manure conveyor belt 1 with certain movement rules;

[0035] Such as figure 1 , the transportation of feces is to transport the pollution out in time by the feces conveyor belt 1, and the conveying speed and conveying time are set under the influence of the breeding objects. The excrement conveyor belt ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com