Preparation of soluble squid ink melanin after fishy smell removal, and application of soluble squid ink melanin after fishy smell removal in foods

A technology of melanin and squid ink, which is applied in food ingredients as antioxidants, food science and other directions, can solve the problems of deodorization of squid ink, unsuitable products for processing and production, etc., and achieves high application potential, abundant raw materials, and simple preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

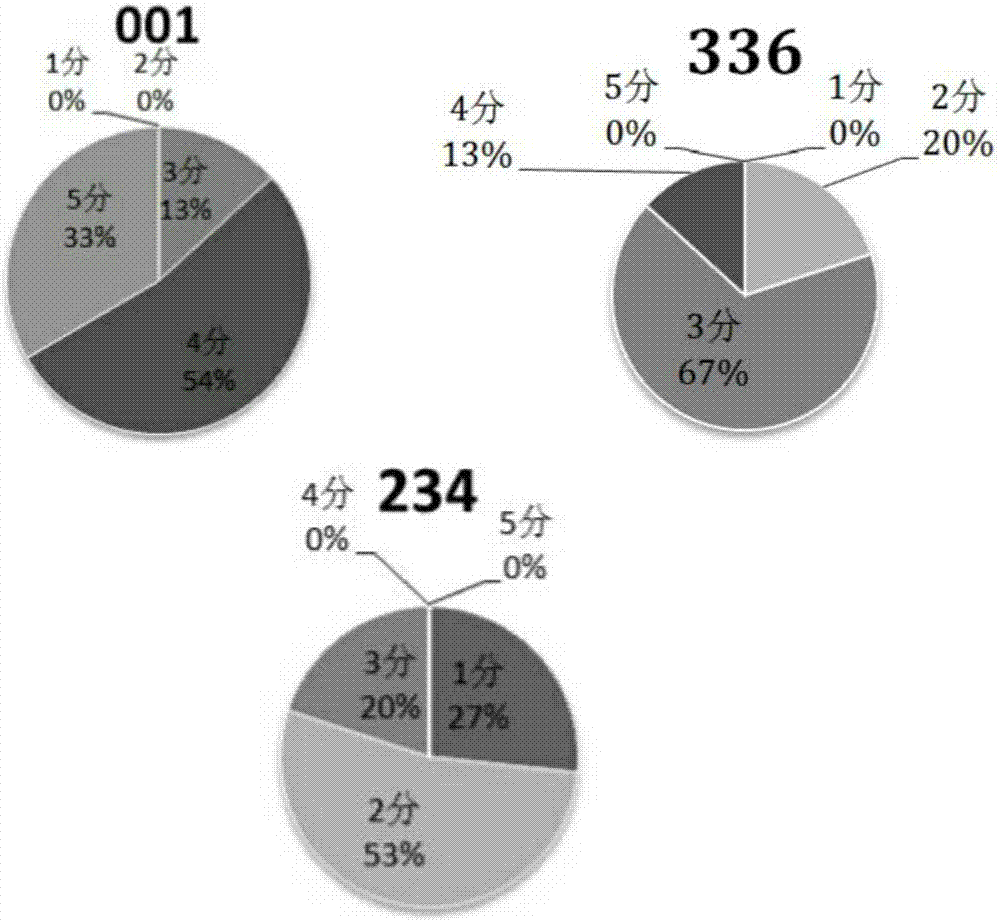

[0050] Thaw the squid ink sac at 0°C, soak it in the ice-water mixture overnight to thaw, add deionized water, centrifuge at 20°C, 10000r / min for 20min, discard the supernatant; obtain a precipitate; add citric acid / sesamol / Ethanol compound deodorizing agent (mass ratio of precipitation to deodorizing agent is 1:3, deodorizing agent is 0.4g sesamol and 1.0g citric acid dissolved in 100mL ethanol), stirring at low temperature for 40min, at 20°C, 8000r / min Discard the supernatant after centrifugation for 20 minutes; dry the precipitate at 55°C for sensory evaluation of fishy smell. So far, sensory evaluation is still considered to be the most convenient, efficient and effective method for fishy odor research. Human beings have the ability to detect many effective odors at extremely low concentrations, which still exceeds the sensitivity of instrumental methods in chemical analysis.

[0051] Among them, the squid ink melanin that has not been washed and deodorized is used as a ...

Embodiment 2

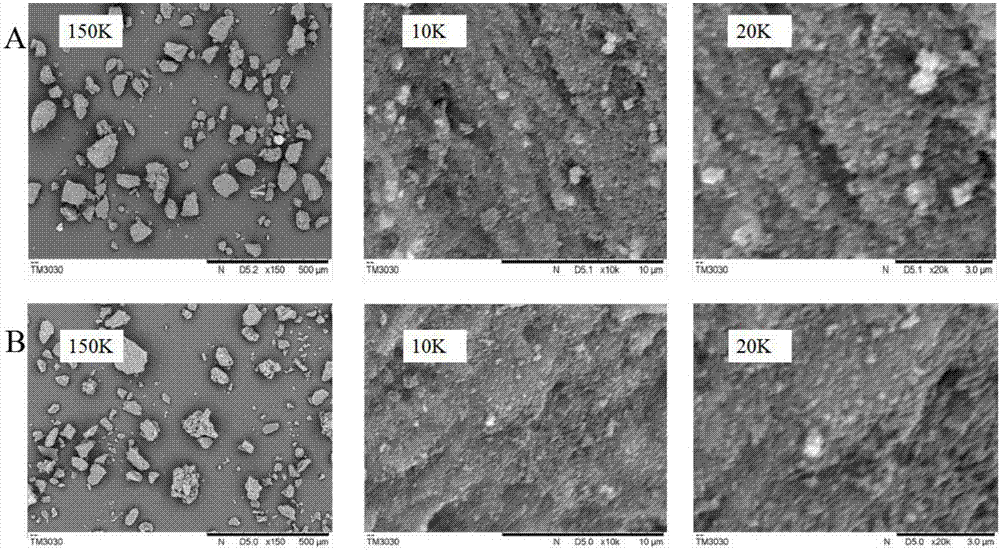

[0055] Thaw the squid ink sac at 0°C, soak it in the ice-water mixture overnight to thaw, add deionized water, centrifuge at 20°C, 10000r / min for 20min, discard the supernatant; obtain a precipitate; add citric acid / sesamol / Ethanol compound deodorizing agent (mass ratio of precipitation to deodorizing agent is 1:3, deodorizing agent is 0.4g sesamol and 1.0g citric acid dissolved in 100mL ethanol), stirring at low temperature for 40min, at 20°C, 8000r / min Discard the supernatant after centrifugation for 20 min; add a small amount of deionized water to the precipitated part, centrifuge at 8000 r / min at 20°C for 20 min, discard the supernatant, and repeat 8 times. Dry and freeze-dry the obtained precipitate at 50°C respectively to obtain the insoluble melanin sample; the yield of the insoluble squid ink melanin prepared by this method is 2% to 4%. Insoluble squid ink melanin carries out scanning electron microscope observation, and the result is as follows ( figure 2 ), it can...

Embodiment 3

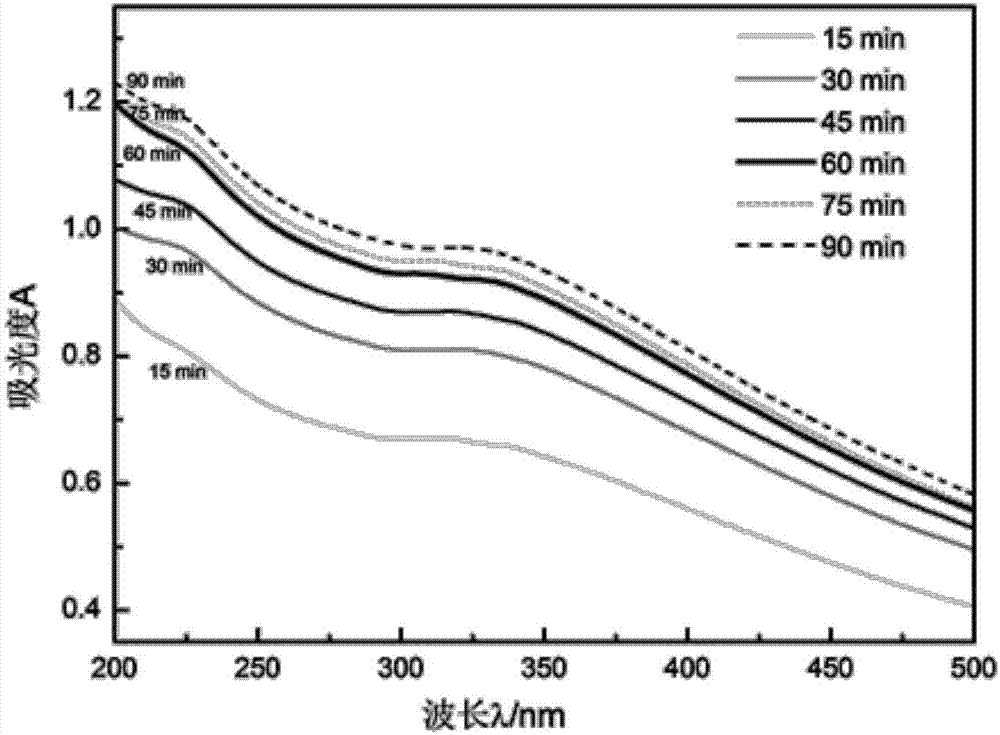

[0057] The insoluble melanin sample obtained in Example 2 was taken and dispersed in deionized water (the ratio of precipitate to deionized water was 1.0 g of precipitate / 25 mL of deionized water). Treat in 350W ultrasonic wave for 15min, 30min, 45min, 60min, 75min, 90min respectively; after cooling to room temperature, take the mixed solution in a centrifuge tube, centrifuge at 20℃, 8000r / min for 20min, discard the precipitate, and take the supernatant to freeze The soluble melanin samples were obtained after drying, and the ultraviolet analysis was carried out on the melanin treated with different ultrasonic time ( image 3 ), it can be seen that the longer the ultrasonic time is, the higher the soluble melanin content is obtained, and the soluble melanin concentration increases slowly after the ultrasonic time exceeds 60 min. After ultrasonic treatment, insoluble squid ink melanin can be completely converted into soluble squid ink melanin. 100-500 mg of insoluble melanin c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com