Novel method for improving the foaming properties of cleaning compositions for topical use

A compositional, linear technology for use in the cosmetic and/or pharmaceutical industries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

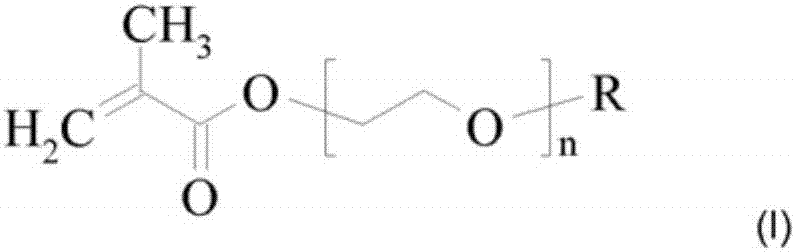

Image

Examples

Embodiment 1

[0165] 1.1. Preparation of ammonium 2-methyl 2-[(1-oxo2-propenyl)amino]1-propanesulfonate, N,N-dimethyl Terpolymer of acrylamide and tetraethoxylated lauryl methacrylate [AMPS / DMAM / MAL (40E) 77.4 / 19.2 / 3.4 moles] [Example of the present invention]

[0166] 592 g of a 15% by mass aqueous solution of 2-methyl 2-[(1-oxo2-propenyl)amino]1-propanesulfonate ammonium in a tert-butanol / water mixture (97.5 / 2.5 volume), 10.1 g of N,N-dimethylacrylamide, 4.2 g of tetraethoxylated lauryl methacrylate and 0.75 g of trimethylolpropane triacrylate were charged into a reactor maintained at 25°C under stirring.

[0167] After a time sufficient to achieve good homogenization of the solution, the solution was deoxygenated by bubbling nitrogen gas heated to 70°C. Then 0.42 g of dilauroyl peroxide are added and the reaction medium is then kept at 70° C. for about 60 minutes and then at 80° C. for 2 hours.

[0168] After cooling, the powder formed during the polymerization was filtered and dried t...

Embodiment 2

[0182] A—Preparation of cleaning compositions comprising polyelectrolyte 1, and comparative formulations

[0183] Pour water into the beaker at 20°C in the mass ratios listed in Table 1, then gradually pour the foaming surfactant with mechanical stirring at 50 rpm, then gradually pour the thickener, then the neutralizer (acidic or basic, depending on the formulation) to obtain the desired pH. Inventive formulations (F1), (F11), (F12) and (F13) and comparative formulations (F2)-(F10) were obtained.

[0184] Table 1

[0185]

(F1)

(F2)

(F3)

(F4)

Sodium Laureth Sulfate (2.2OE) (27.1% M.A.)

44.3%

44.3%

44.3%

44.3%

Amonyl TM 380 BA (1) (28.9% M.A.)

10.4%

10.4%

10.4%

10.4%

Amonyl TM 675 SB (2) (38.44% M.A.)

0%

0%

0%

0%

water

44.3%

43.6%

42.4%

42.5%

45% lactic acid solution

0.2%

0.2%

0%

0%

10% citric acid solution

0%

0%

0%

0.5%

50% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com