Method for fast modifying surface of palladium catalyst

A palladium catalyst and a catalyst technology, applied in the field of nanoscience, can solve the problems of inability to optimize treatment, difficult to prepare in large quantities, complicated methods, etc., and achieve the effects of convenient large-scale modification, low cost, and simple modification process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The method for the rapid modification palladium catalyst surface of the present invention comprises the following steps:

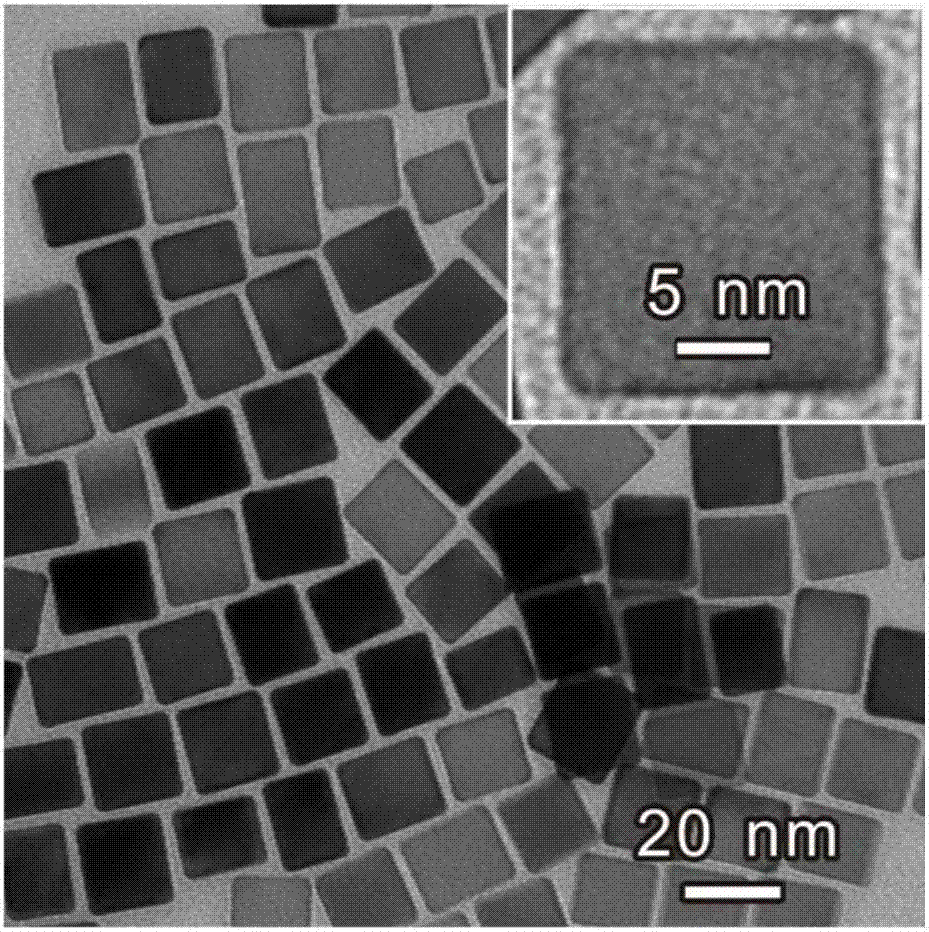

[0044] 1) Disperse 10 mg of palladium cubic nanocrystals in 5 mL of oleylamine to obtain a reaction solution, wherein the concentration of palladium in the reaction solution is 2 mg / mL;

[0045] 2) The reaction solution was stirred in an oil bath at 180° C., and 0.4 mL of tri-n-octyl phosphorus was added to react for 20 seconds, then centrifuged and washed to obtain a modified palladium catalyst, wherein the thickness of the palladium phosphorus layer was 0.3 nm.

Embodiment 2

[0047] The method for the rapid modification palladium catalyst surface of the present invention comprises the following steps:

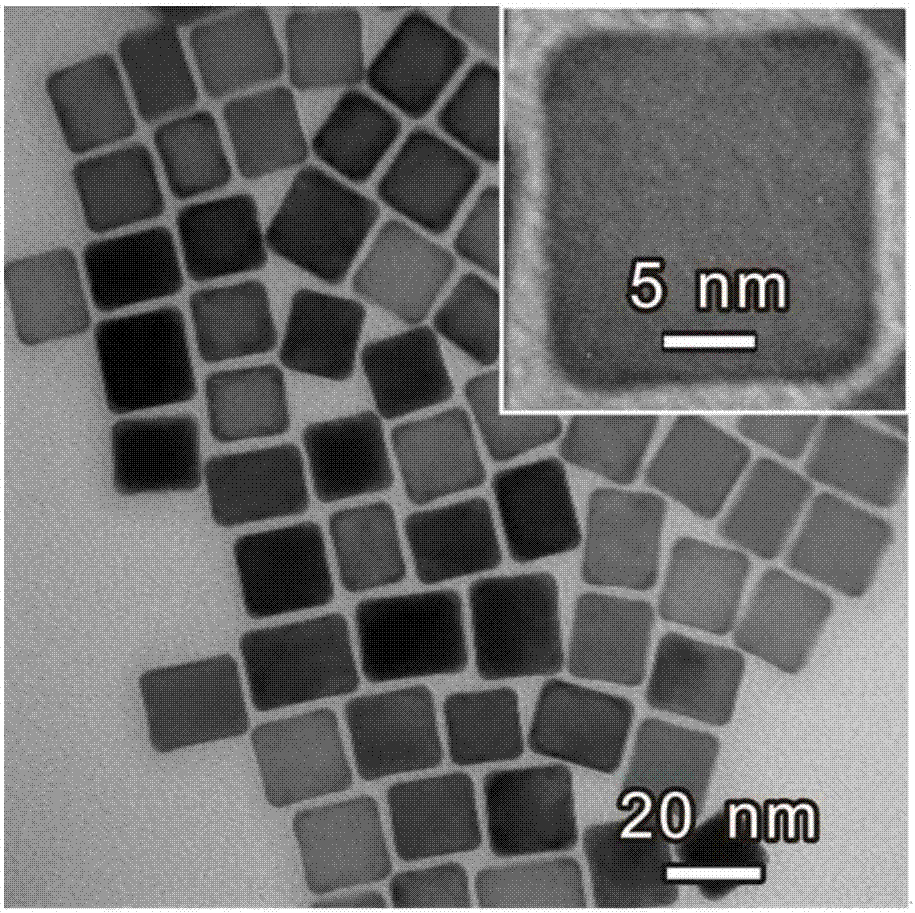

[0048] 1) Disperse 10 mg of palladium cubic nanocrystals in 5 mL of oleylamine to obtain a reaction solution, the concentration of palladium in the reaction solution is 2 mg / mL;

[0049] 2) The reaction solution was stirred in an oil bath at 180° C., and 0.4 mL of tri-n-octylphosphine was added to react for 1 minute, and then centrifuged and washed to obtain a modified palladium catalyst, wherein the palladium-phosphorus layer The thickness is 0.5 nm.

Embodiment 3

[0051] The method for the rapid modification palladium catalyst surface of the present invention comprises the following steps:

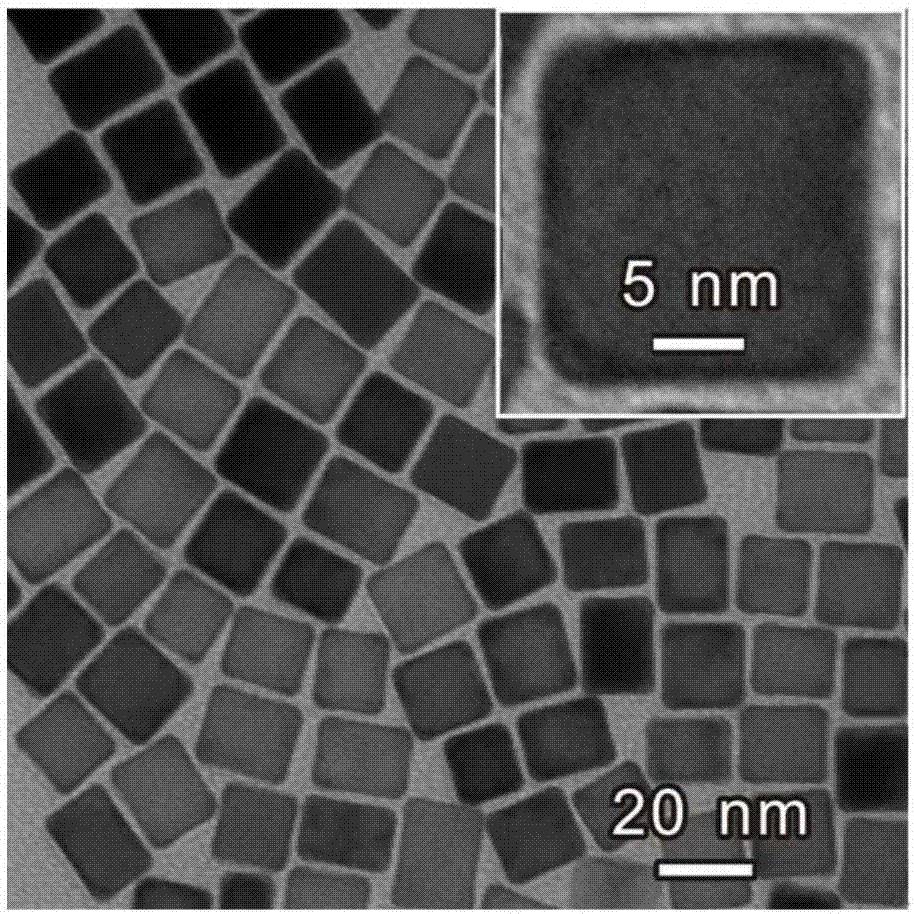

[0052] 1) Disperse 10 mg of palladium cubic nanocrystals in 5 mL of oleylamine to obtain a reaction solution, the concentration of palladium in the reaction solution is 2 mg / mL;

[0053]2) The reaction solution was stirred in an oil bath at 180°C, and 0.4 mL of tri-n-octylphosphine was added to react for 2 minutes, and then centrifuged and washed to obtain a modified palladium catalyst, wherein the palladium-phosphorus layer The thickness is 0.7 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com