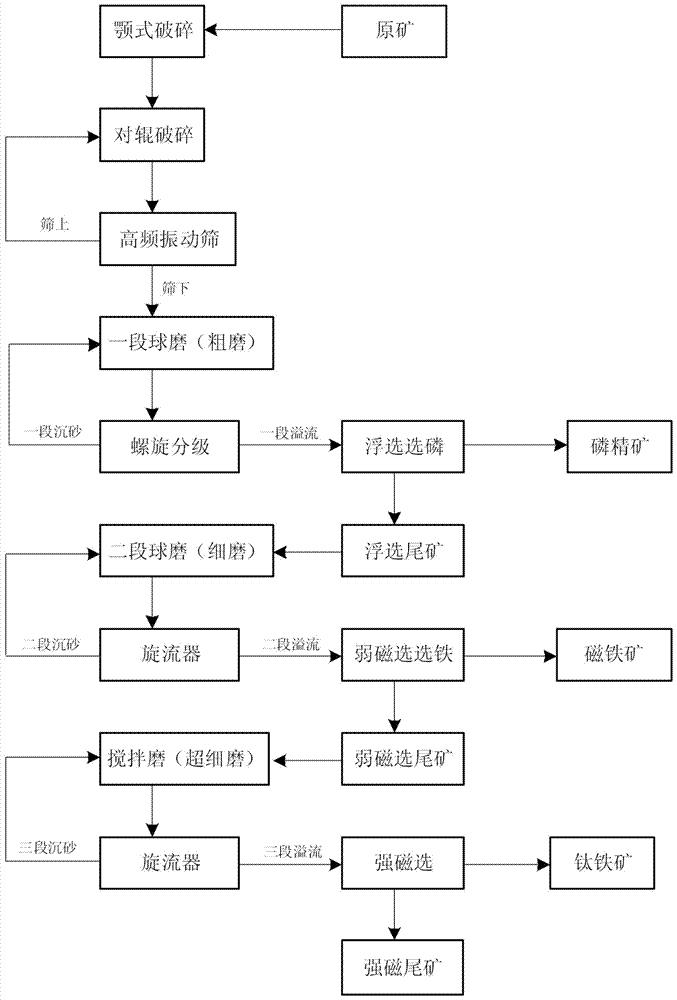

Method for comprehensively recovering phosphorus, iron and titanium minerals in magmatic rock type phosphorite

A technology of magmatic rocks and titanium minerals, applied in the field of mineral processing, can solve the problems of small processing capacity, low recovery rate, and difficult flotation separation, and achieve the effect of avoiding over-grinding of minerals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The magmatic rock-type phosphate rock comes from a low-grade ore containing phosphorus, iron and titanium in Chengde, Hebei; the composition is shown in Table 1 (weight percentage);

[0033] Table 1

[0034] Element

P 2 o 5

TF

TiO 2

SiO 2

Al 2 o 3

CaO

MgO

content / %

2.22

10.31

2.25

44.63

13.90

8.07

4.86

[0035] Coarsely crush the raw ore of igneous rock-type phosphate rock to a particle size of 30mm~50mm to obtain coarsely crushed ore;

[0036] The coarse crushed ore is finely crushed and then screened. The sieve hole size during screening is 3mm, and the fine crushed ore under the screen is obtained; the on-screen material obtained by screening is returned to the fine crushing process

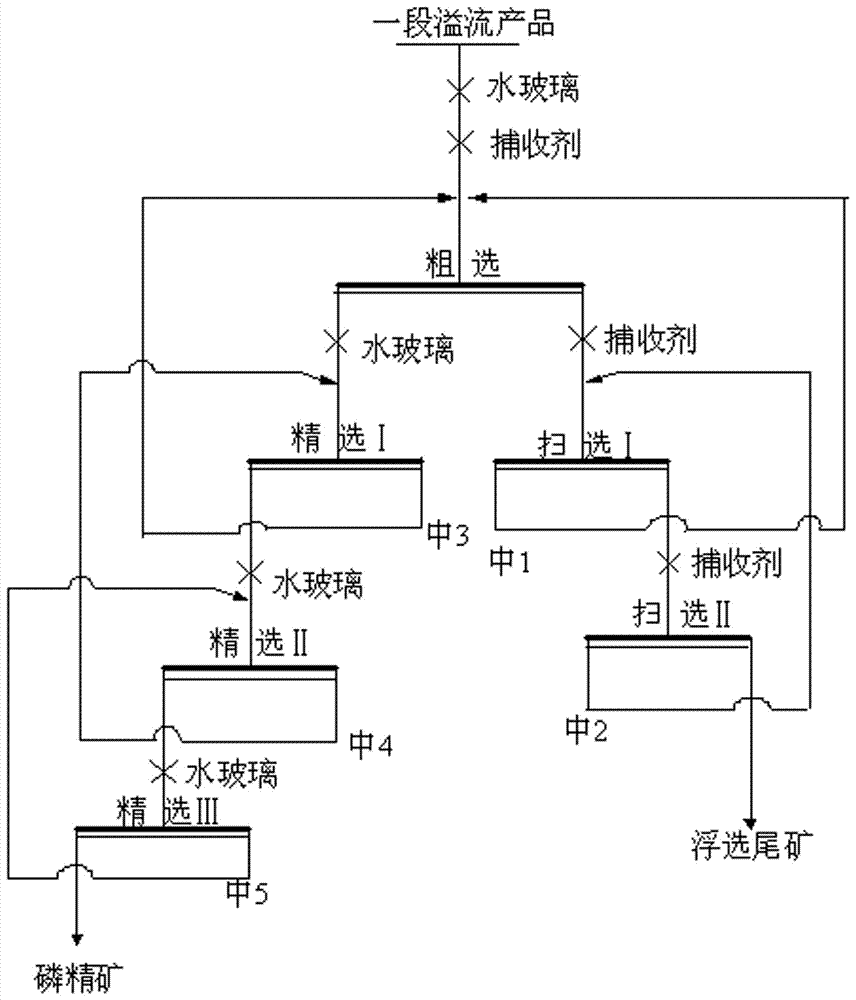

[0037] Feed the finely crushed ore into a ball mill for coarse grinding, the concentration of the grinding pulp is 50%, and classify with a spiral classifier to obtain a section of overflow product with a...

Embodiment 2

[0045] Method is with embodiment 1, and difference is:

[0046] (1) The size of the sieve hole during screening is 2mm; the concentration of the grinding pulp is 60%,

[0047] (2) The reagent system for roughing is: for raw ore feed, the dosage of water glass is 600g / t, and the dosage of collector is 1000g / t. At this time, the pH value of the roughing pulp is 7.5, and the mass concentration of the pulp is 35%. The rougher concentrates are subjected to three times of beneficiation to obtain phosphorous concentrates. The beneficiation system is as follows: for the raw ore feed, the amount of water glass for each beneficiation is 150g / t; the rougher tailings obtained by rougher are cleaned twice. The flotation tailings are selected, and the scavenging reagent system is as follows: for the raw ore feed, the amount of collector used for each scavenging is 250g / t;

[0048] (3) The roughing time is 4 minutes, the selection and sweeping time is 3 minutes, and the flotation temperatur...

Embodiment 3

[0053] Method is with embodiment 1, and difference is:

[0054] (1) The sieve hole size during sieving is 5mm; the concentration of the grinding pulp is 70%,

[0055] (2) The roughing agent system is: for raw ore feed, the amount of water glass is 800g / t, and the amount of collector is 1200g / t. At this time, the pH value of the roughing pulp is 8, and the mass concentration of the pulp is 40%. The rougher concentrates are subjected to three times of beneficiation to obtain phosphorous concentrates. The beneficiation system is as follows: for the raw ore feed, the amount of water glass for each beneficiation is 200g / t; the rougher tailings obtained by rougher are cleaned twice. The flotation tailings are selected, and the scavenging reagent system is as follows: for the raw ore feed, the amount of collector for each scavenging is 300g / t;

[0056] (3) The roughing time is 6 minutes, the selection and sweeping time is 3 minutes, and the flotation temperature is 40°C;

[0057] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com