Device and method for removing ultrasonic electrochemical radioactive contaminations of nuclear facilities

A technology of ultrasonic electrochemistry and decontamination device, which is applied in the direction of chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., which can solve the problems of unsatisfactory decontamination effects such as waste and waste liquid, and achieve excellent corrosion resistance performance, long electrode life, and less secondary waste generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

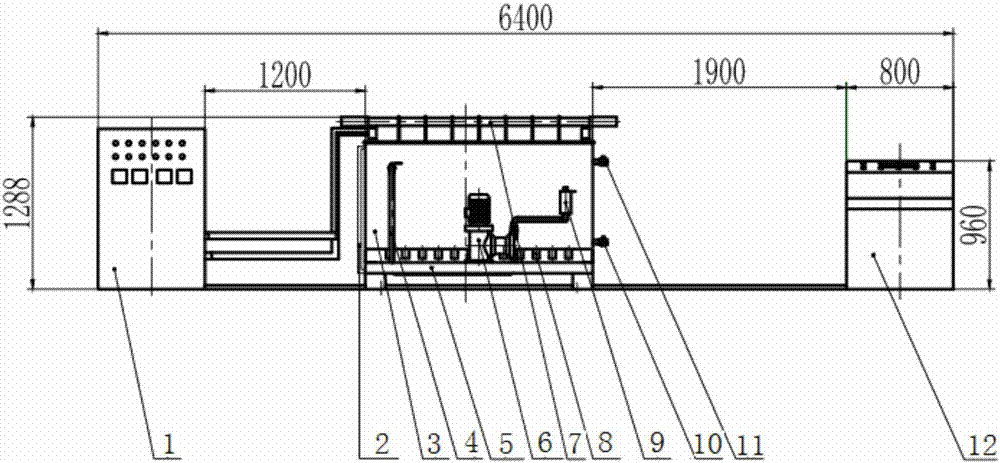

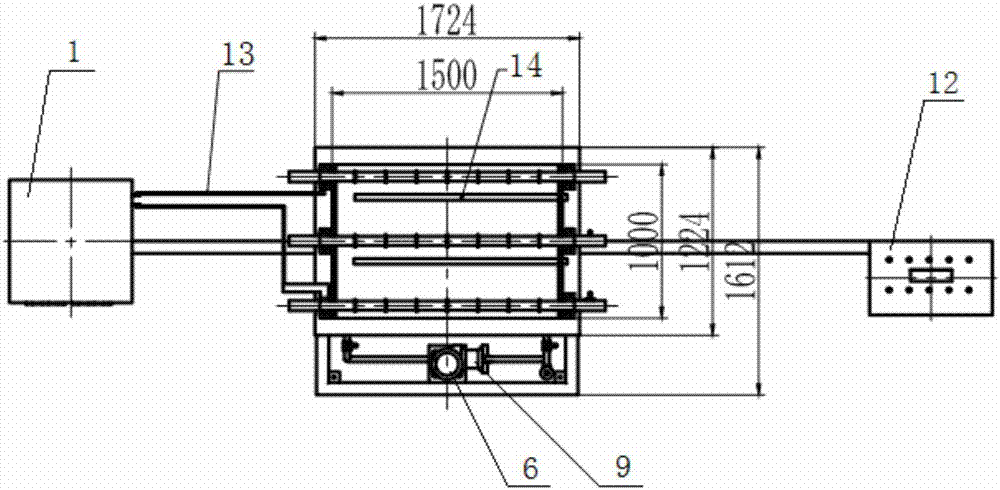

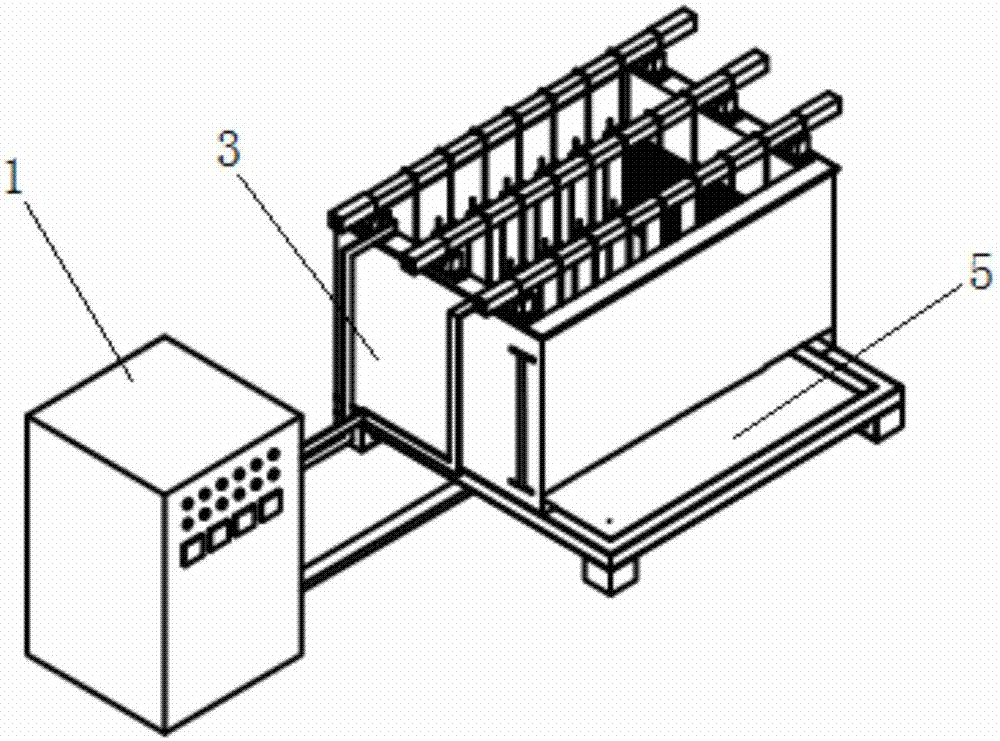

[0032] Such as Figure 1-Figure 3 As shown, the ultrasonic electrochemical radioactive pollution decontamination device for nuclear facilities of the present invention has the advantages of both ultrasonic decontamination and electrochemical decontamination methods, and mainly includes an electrochemical decontamination system, an ultrasonic decontamination system, a heating system, an electrolytic decontamination system, and an electrolytic decontamination system. Liquid circulation system and controller, the specific structure is as follows:

[0033] (1) The electrochemical decontamination system comprises electrochemical power source 1, electrode 7, three parts of electrochemical decontamination tank 3, and electrode 7 is arranged in the electrochemical decontamination tank 3, and the input terminal of electrochemical power source 1 is connected with control by wire 13 The output end of the electrochemical power supply 1 is connected to the electrode 7 through the wire 13. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com