Manufacturing method and device of electromagnetic shielding part, terminal, computer readable storage medium and electromagnetic shielding part

A technology of electromagnetic shielding and manufacturing method, applied in the field of 3D printing, can solve the problems of structural limitation, affecting the heat dissipation of the chip, heavy weight, etc., to achieve the effect of easy modification, high precision and flexibility, and easy modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

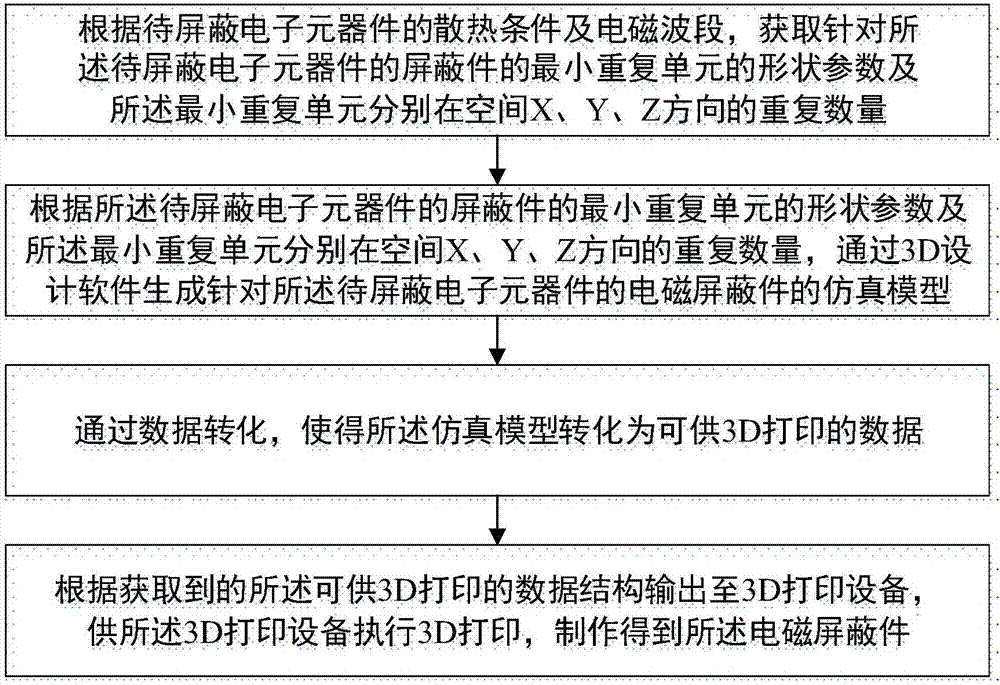

[0054] See attached figure 1 , The manufacturing method of the electromagnetic shield provided by the first embodiment of the present invention includes the following steps:

[0055] Step S1: According to the heat dissipation conditions and the electromagnetic wave band of the electronic components to be shielded, the shape parameters of the smallest repeating unit of the shielding member for the electronic components to be shielded and the number of repetitions of the smallest repeating unit in the X, Y, and Z directions of the space are obtained;

[0056] Step S2: According to the shape parameters of the smallest repeating unit of the shielding part of the electronic component to be shielded and the number of repetitions of the smallest repeating unit in the X, Y, and Z directions of the space, generate electromagnetic shielding for the electronic component to be shielded by 3D design software The simulation model of the piece;

[0057] Step S3: Transform the simulation mod...

Embodiment 2

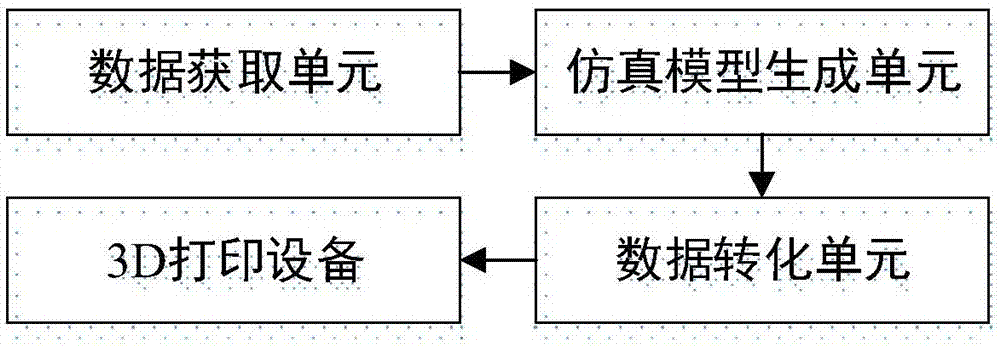

[0067] See attached figure 2 , the manufacturing device of the electromagnetic shielding member provided by Embodiment 2 of the present invention includes:

[0068] The data acquisition unit is used to obtain the shape parameters of the smallest repeating unit of the shielding member of the electronic component to be shielded and the shape parameters of the smallest repeating unit in the X, Y, and Z directions of space, respectively, according to the heat dissipation conditions and the electromagnetic wave band of the electronic component to be shielded. number of repetitions;

[0069] The simulation model generation unit is used to generate the electronic components to be shielded through 3D design software according to the shape parameters of the smallest repeating unit of the shielding part of the electronic component to be shielded and the repetition numbers of the smallest repeating unit in the X, Y, and Z directions of space respectively. The simulation model of the el...

Embodiment 3

[0074] The terminal provided by Embodiment 3 of the present invention includes a processor, a memory, a program for making an electromagnetic shield that is stored in the memory and can run on the processor, and a 3D printing device. The steps of the manufacturing method of the electromagnetic shield provided by the present invention when the production program of the electromagnetic shield is executed by the processor; the 3D printing device is used to perform 3D printing according to the production program of the electromagnetic shield to produce the electromagnetic shield.

[0075] In the process of preparing the electromagnetic shielding part by using the joint application of the terminal and the 3D printing equipment provided by Embodiment 3 of the present invention, firstly, according to the heat dissipation conditions and the electromagnetic wave band of the electronic component to be shielded, the minimum repetition of the shielding part for the electronic component to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com