Low-temperature solid propellant

A solid propellant and low-temperature technology, applied to explosives and other fields, to achieve the effects of easy availability of raw material resources, cost savings, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

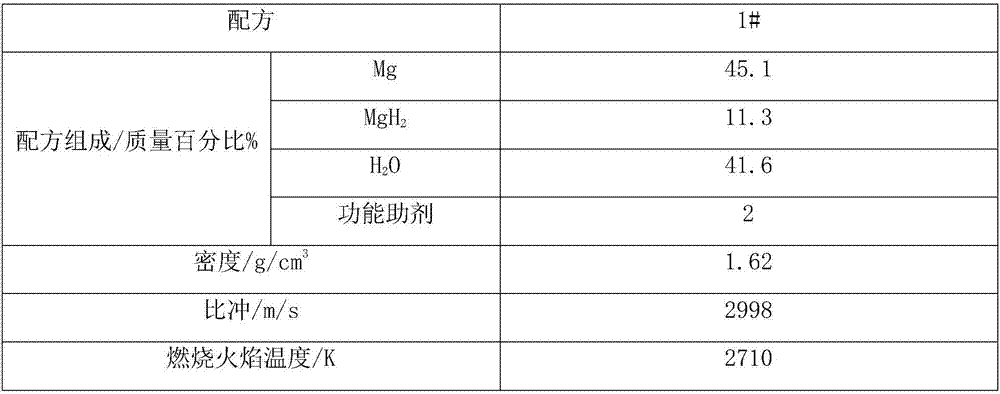

Embodiment 1

[0022] The mass ratio of each component is: metal magnesium powder (Mg): 45.1%; magnesium dihydride (MgH 2 ): 11.3%; deionized water: 41.6%; functional additives: 2%.

[0023] The magnesium powder is a composite magnesium powder composed of ultra-fine magnesium powder and conventional magnesium powder. The particle size of the ultra-fine magnesium powder is 100 nm-1 μm; the particle size of the conventional magnesium powder is 1 μm-100 μm. In the composite magnesium powder, the ultrafine magnesium powder accounts for 60% of the mass of the composite magnesium powder, and the rest is conventional magnesium powder. The purity of the ultrafine magnesium powder is greater than 99%.

[0024] The particle size of the magnesium dihydride is 1 μm-100 μm.

[0025] The functional aid is a combination of stabilizer, process aid and combustion aid. The stabilizer is MNA (N-methyl-p-nitroaniline) with a content of 0.5%; the process aid is sodium dodecyl sulfonate with a content of 1%; t...

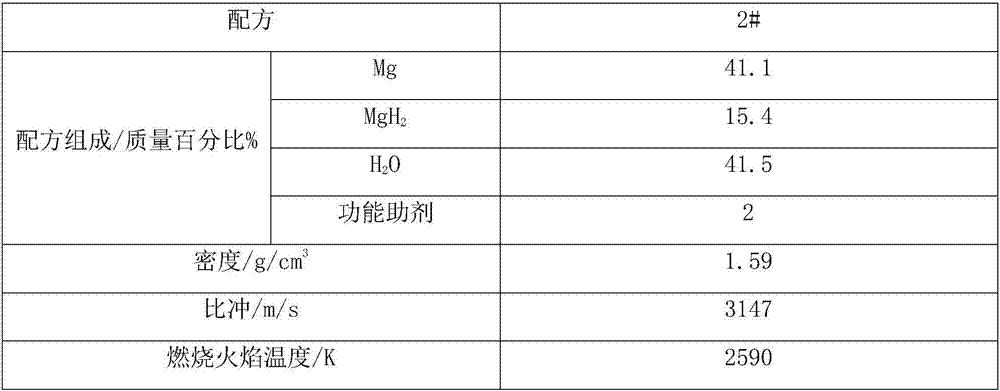

Embodiment 2

[0031] Table 2 below provides 2#Mg / MgH of the present invention 2 / H 2 Formulation components and properties of low-temperature solid propellants

[0032] Table 2 Mg / MgH 2 / H 2 O

[0033]

[0034] It can be seen from Table 2 that when Mg / MgH 2 / H 2 MgH in low temperature solid propellants 2 When the mass fraction increased to 15.4%, the density of the propellant was 1.59 g / cm lower than that of Example 1. 3 , the specific impulse increased to 3147m / s, and the flame temperature decreased to 2590K.

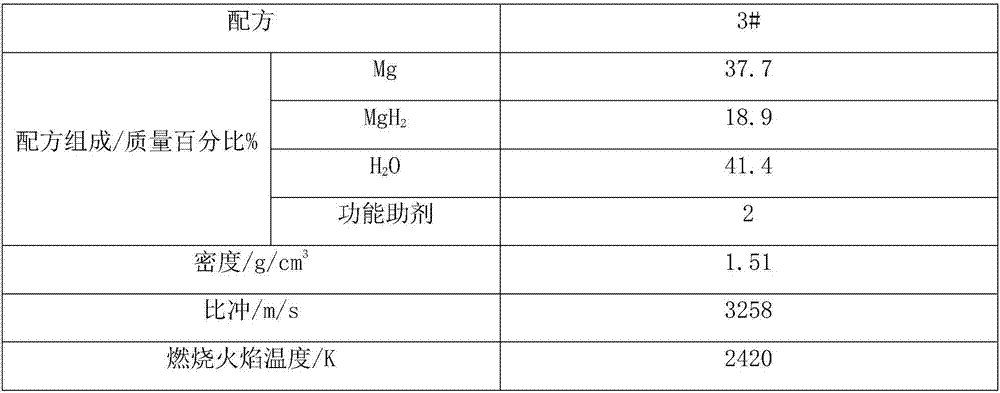

Embodiment 3

[0036] Table 3 below provides 3#Mg / MgH of the present invention 2 / H 2 Formulation components and properties of low-temperature solid propellants

[0037] Table 3 Mg / MgH 2 / H 2 O

[0038]

[0039] It can be seen from Table 3 that when Mg / MgH 2 / H 2 MgH in low temperature solid propellants 2 When the mass fraction increased to 18.9%, the propellant density was further reduced to 1.51g / cm 3 , the specific impulse increases to 3258m / s, and the flame temperature drops to 2420K.

[0040] It can be seen from the above examples that the present invention greatly improves the specific impulse of the propellant and other properties of the propellant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com